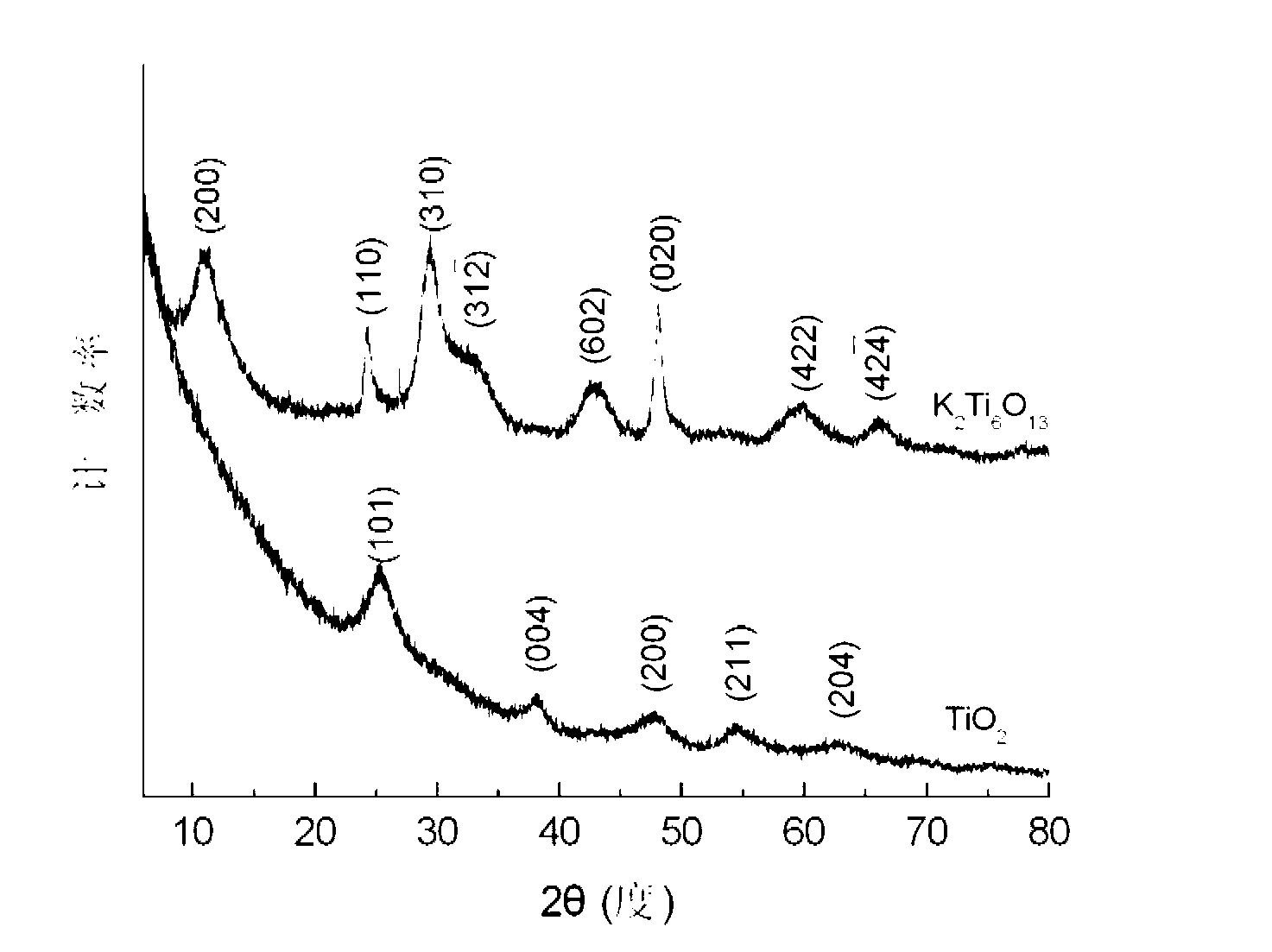

Preparing method of nano band potassium titanate (K2Ti6O13)

A technology of potassium hexatitanate and ribbons, which is applied in the field of preparation of nanoribbon-shaped potassium hexatitanate, which can solve problems affecting the size uniformity of hydrothermal products, uneven diameters of potassium titanate nanowires, and weak light absorption properties. , to achieve the effect of improving the efficiency of hydrothermal reaction, realizing controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In the first step, TiO was prepared by sol-gel method 2 Nano powder

[0029] Using butyl titanate as the precursor, mix butyl titanate and absolute ethanol at a ratio of 1:1 to form a uniform solution, prepare solution A, add 2% nitric acid and 5% sodium polyacrylate solution in distilled water for magnetic stirring, The volume ratio of distilled water: 2% nitric acid: 5% sodium polyacrylate is 75:2.5:1, and it is prepared into solution B, and then the required amount of solution A is added into solution B, and the volume ratio of solution A to solution B is 1: 5. Hydrolyze at room temperature, stir for 2 hours and then filter and dry the resulting white precipitate to obtain anatase phase white TiO 2 Nanopowder, the particle size of which is between 4nm and 10nm, and the above percentages are mass percent concentrations;

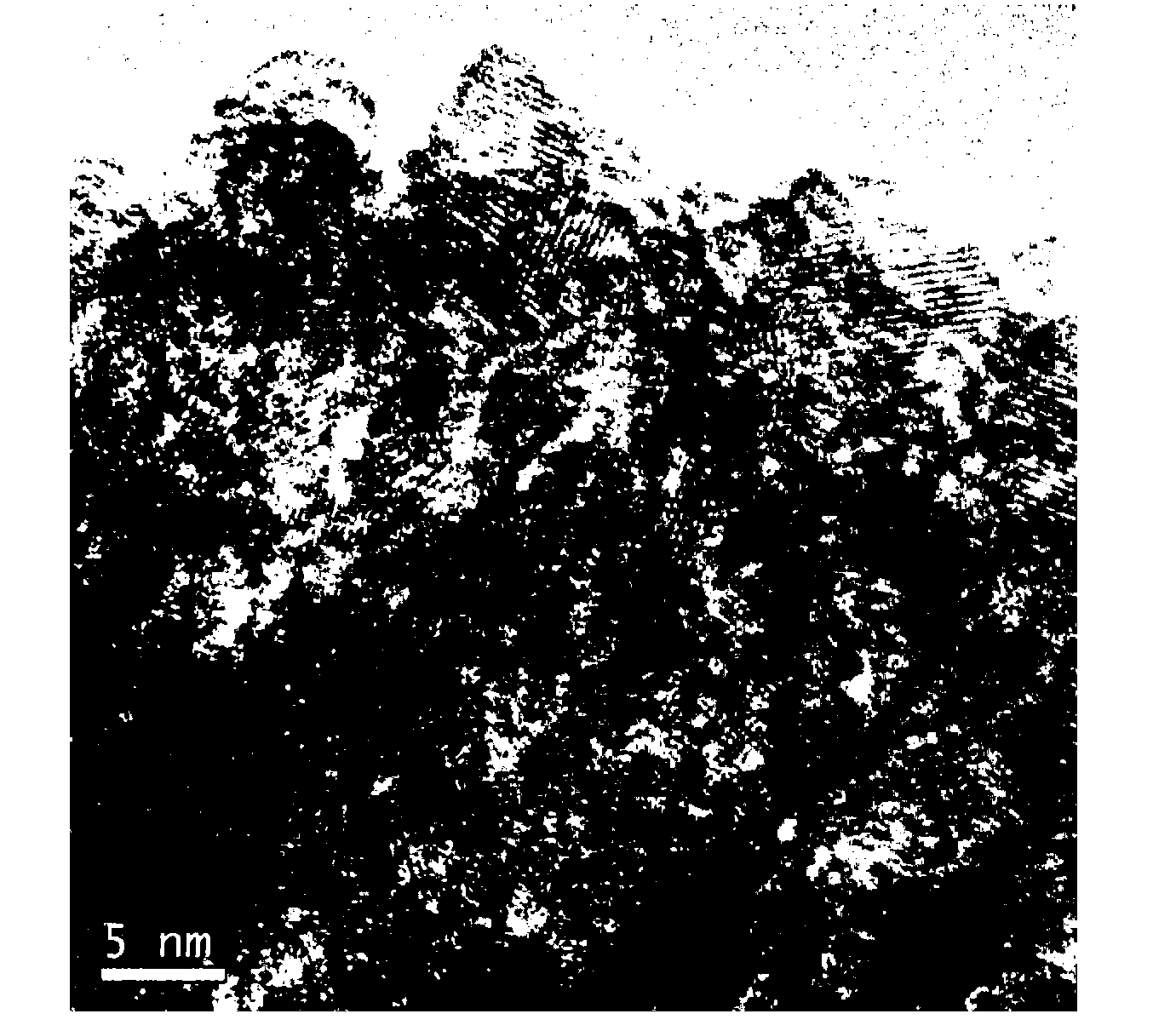

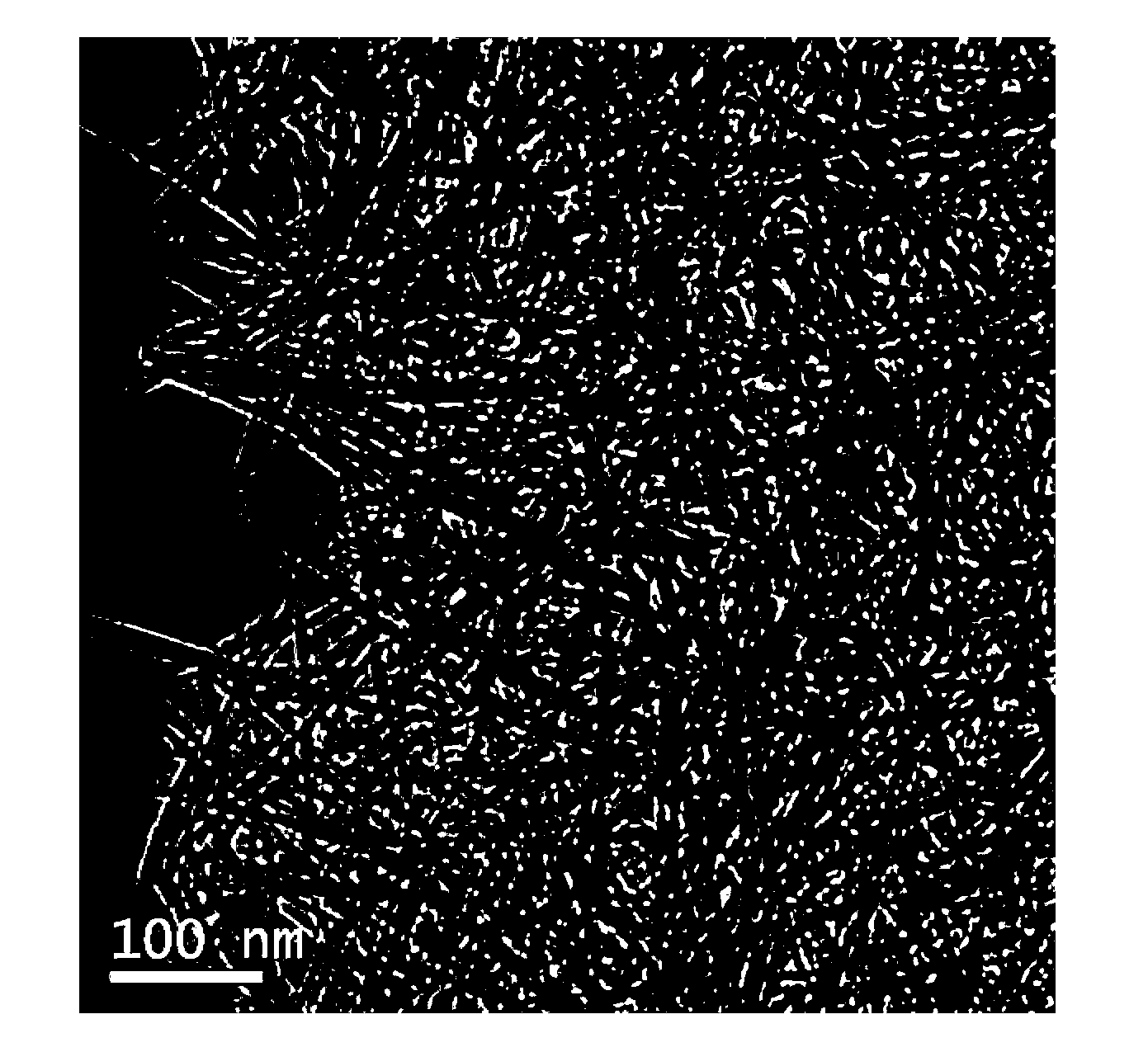

[0030] In the second step, the nanoribbon-like K 2 Ti 6 o 13 One-dimensional nanomaterials

[0031] Take 1g of TiO produced in the first step ...

Embodiment 2

[0035] In the first step, TiO was prepared by sol-gel method 2 Nano powder

[0036] Using butyl titanate as the precursor, mix butyl titanate and absolute ethanol at a ratio of 1:1 to form a uniform solution, prepare solution A, add 2% nitric acid and 5% sodium polyacrylate solution in distilled water for magnetic stirring, The volume ratio of distilled water: 2% nitric acid: 5% sodium polyacrylate is 75:2.5:1, and it is prepared into solution B, and then the required amount of solution A is added into solution B, and the volume ratio of solution A to solution B is 1: 5. Hydrolyze at room temperature, stir for 2 hours and then filter and dry the resulting white precipitate to obtain anatase phase white TiO 2 Nanopowder, the particle size of which is between 4nm and 10nm, and the above percentages are mass percent concentrations;

[0037] In the second step, the nanoribbon-like K 2 Ti 6 o 13 One-dimensional nanomaterials

[0038] Get 2.25g of the TiO produced in the first...

Embodiment 3

[0042] In the first step, TiO was prepared by sol-gel method 2 Nano powder

[0043] Using butyl titanate as the precursor, mix butyl titanate and absolute ethanol at a ratio of 1:1 to form a uniform solution, prepare solution A, add 2% nitric acid and 5% sodium polyacrylate solution in distilled water for magnetic stirring, The volume ratio of distilled water: 2% nitric acid: 5% sodium polyacrylate is 75:2.5:1, and it is prepared into solution B, and then the required amount of solution A is added into solution B, and the volume ratio of solution A to solution B is 1: 5. Hydrolyze at room temperature, stir for 2 hours and then filter and dry the resulting white precipitate to obtain anatase phase white TiO 2 Nanopowder, the particle size of which is between 4nm and 10nm, and the above percentages are mass percent concentrations;

[0044] In the second step, the nanoribbon-like K 2 Ti 6 o 13 One-dimensional nanomaterials

[0045] Take 5g of TiO produced in the first step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com