Printing and dyeing wastewater treatment system and printing and dyeing wastewater treatment method

A printing and dyeing wastewater and treatment system technology, applied in water/sewage treatment, special compound water treatment, light water/sewage treatment, etc., can solve the problems of complex components of printing and dyeing wastewater, increased treatment costs, and great environmental hazards, and achieve reduction The use of medicines, the effect of improving the treatment effect, and the effect of strong activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

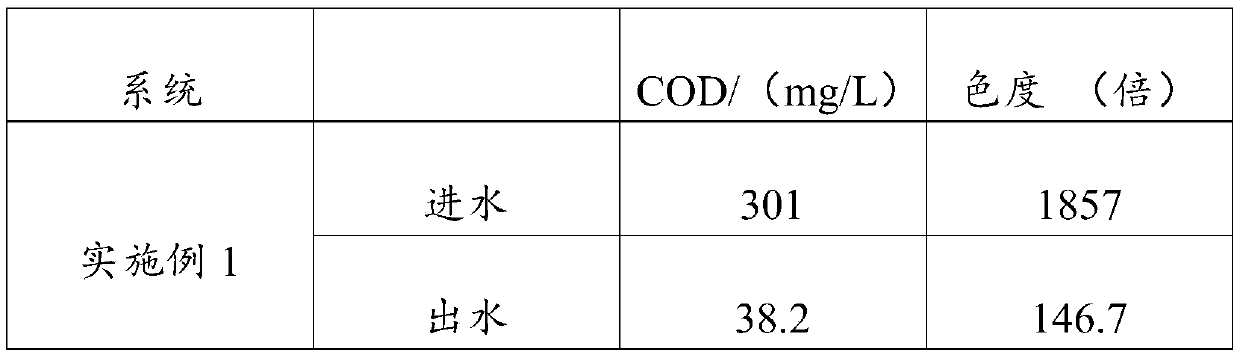

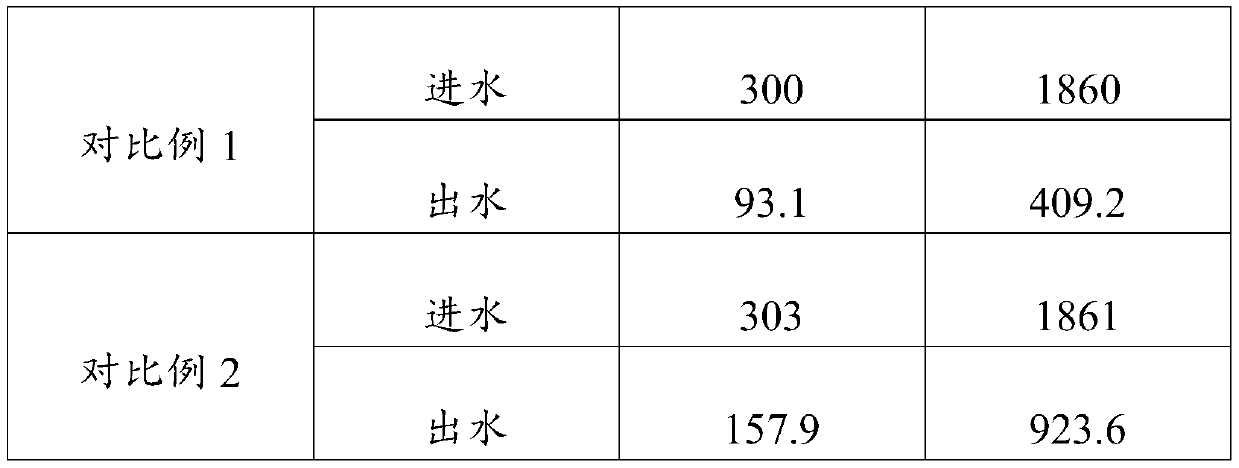

Embodiment 1

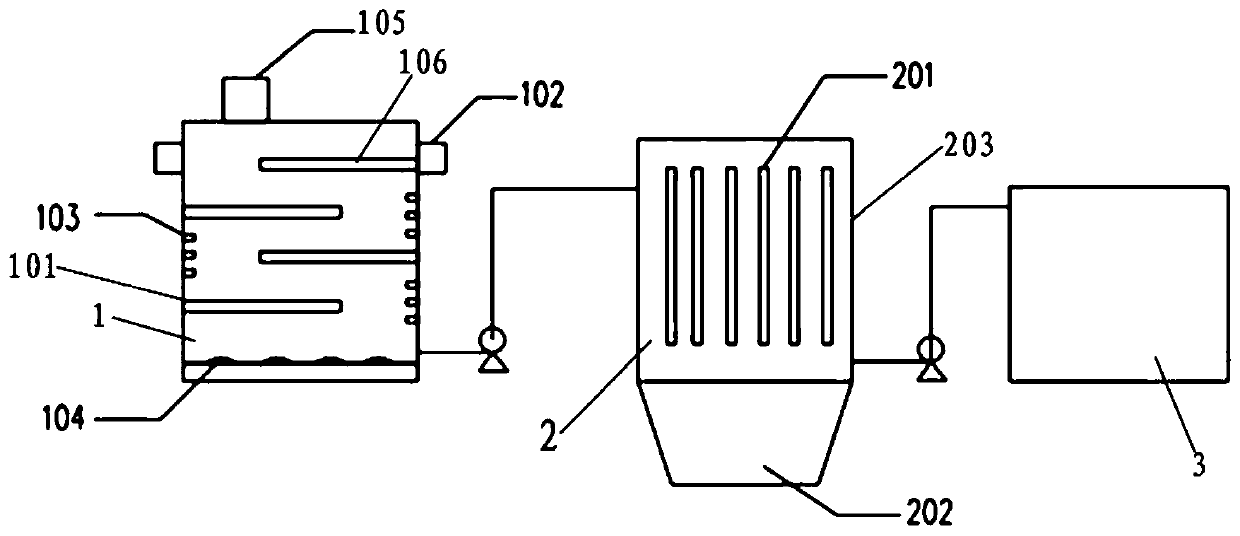

[0031] As a kind of printing and dyeing wastewater treatment system of the embodiment of the present invention, as figure 1 As shown, the printing and dyeing wastewater treatment system includes a microwave photoelectric Fenton treatment unit 1, a magnetic separation unit 2 and a nanofiltration-reverse osmosis unit 3 connected in sequence;

[0032] The microwave photoelectric Fenton processing unit 1 comprises a reaction vessel 101, a microwave generating device, an ultraviolet light generating device 102 and an aeration device, and the reaction container is provided with a water inlet of the microwave photoelectric Fenton processing unit, a water outlet of the microwave photoelectric Fenton processing unit, Solid feed inlet, positive electrode and negative electrode, positive electrode and negative electrode are electrically connected with voltage output device, and microwave generating device comprises microwave output mechanism 103, and the microwave output mechanism 103 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com