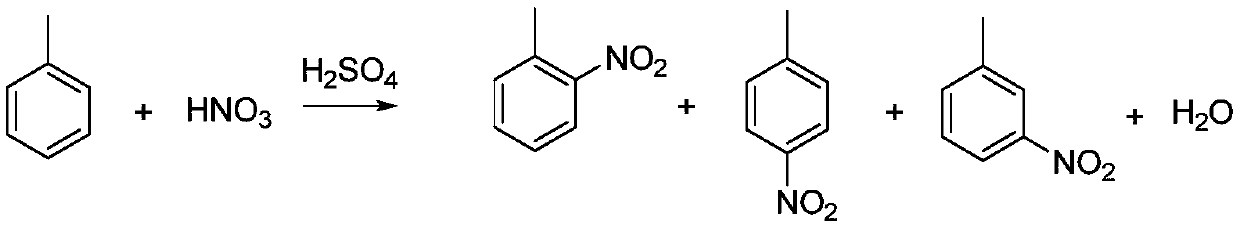

Method for preparing mononitrotoluene by continuously adiabatically nitrifying toluene at high temperature

A technology of mononitrotoluene and nitrated toluene, which is applied in the field of continuous adiabatic high-temperature nitration of toluene to prepare mononitrotoluene, can solve the problems of large liquid holding capacity, low heat transfer efficiency, and out-of-control temperature of the reaction system, and achieve high production efficiency, The effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) the concentrated sulfuric acid that 914g mass percent concentration is 98% is slowly added in 366g water, and preparation mass percent concentration is 1280 grams of 70% dilute sulfuric acid;

[0025] (2) the concentrated nitric acid that 107g mass percentage concentration is 98% is joined in the dilute sulfuric acid solution that the mass percentage concentration of step (1) is 70%, the sulfuric acid solution (mixed acid solution) that prepares nitric acid, this mixed acid solution joins Store in bottle A;

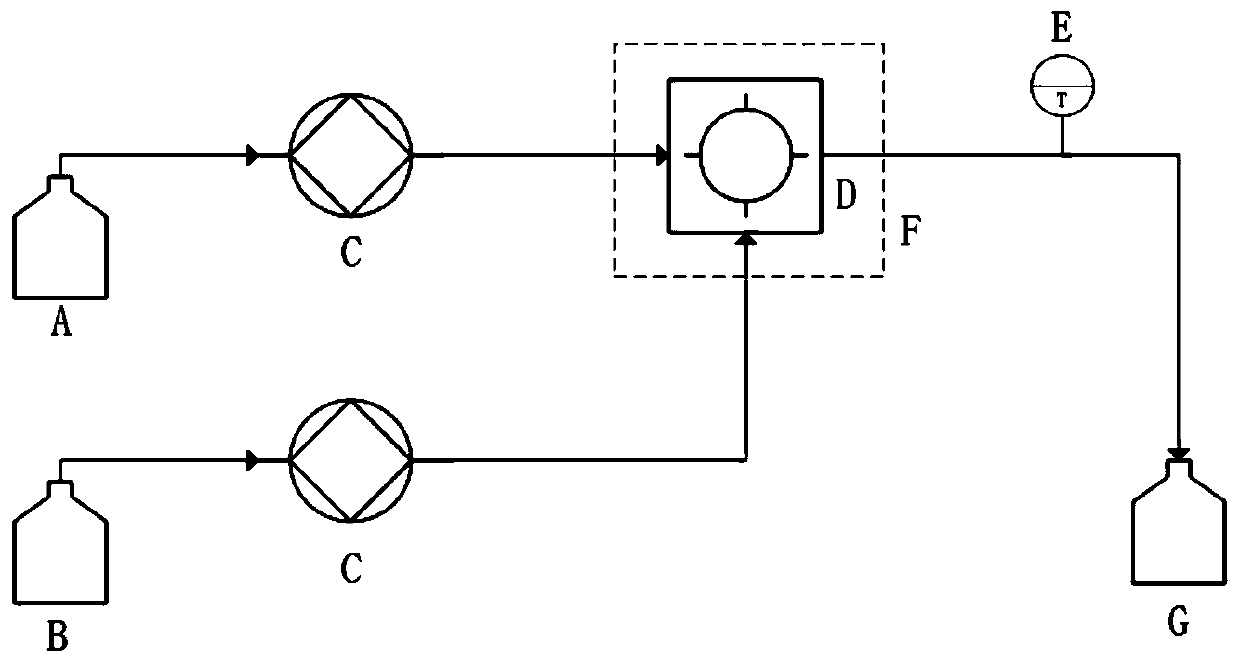

[0026] (3) Toluene is added to storage bottle B, and the mixed acid solution in toluene and storage bottle A (the molar ratio of toluene and nitric acid is 1:1.02) is transported in reactor D through fluid delivery equipment C for rapid mixing and heat insulation High temperature reaction, the control reaction pressure is 0.9 kilograms, and the reaction temperature is 85 degrees centigrade and the reaction time is 45 seconds, and the reaction mixture obtained i...

Embodiment 2

[0030] (1) the concentrated sulfuric acid that 914g mass percent concentration is 98% is slowly added in 366g water, and preparation mass percent concentration is 1280 grams of 70% dilute sulfuric acid;

[0031] (2) the concentrated nitric acid that 107g mass percentage concentration is 98% is joined in the dilute sulfuric acid solution that the mass percentage concentration of step (1) is 70%, the sulfuric acid solution (mixed acid solution) that prepares nitric acid, this mixed acid solution joins Store in bottle A;

[0032] (3) Toluene is added to storage bottle B, and the mixed acid solution in toluene and storage bottle A (the molar ratio of toluene and nitric acid is 1:1.05) is transported in the reactor D through fluid delivery equipment C for rapid mixing and heat insulation High temperature reaction, the control reaction pressure is 0.9 kilograms, and the reaction temperature is 85 degrees centigrade and the reaction time is 45 seconds, and the reaction mixture obtain...

Embodiment 3

[0036] (1) the concentrated sulfuric acid that 914g mass percent concentration is 98% is slowly added in 366g water, and preparation mass percent concentration is 1280 grams of 70% dilute sulfuric acid;

[0037] (2) the concentrated nitric acid that 107g mass percentage concentration is 98% is joined in the dilute sulfuric acid solution that the mass percentage concentration of step (1) is 70%, the sulfuric acid solution (mixed acid solution) that prepares nitric acid, this mixed acid solution joins Store in bottle A;

[0038](3) Toluene is added to storage bottle B, and the mixed acid solution in toluene and storage bottle A (the molar ratio of toluene and nitric acid is 1:1.08) is transported in reactor D through fluid delivery equipment C for rapid mixing and heat insulation High temperature reaction, the control reaction pressure is 0.9 kg, the reaction temperature is 86 degrees Celsius and the reaction time is 45 seconds, and the reaction mixture obtained is stored in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com