Preparation method and device of monochloramine

A monochloramine and ammonium chloride technology, applied in chemical instruments and methods, special treatment targets, inorganic chemistry, etc., can solve the problems of insufficient attention to pH value of reaction control conditions, high degree of automation, and high technical support requirements, and achieve improved Labor production efficiency, saving and its auxiliary equipment, the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

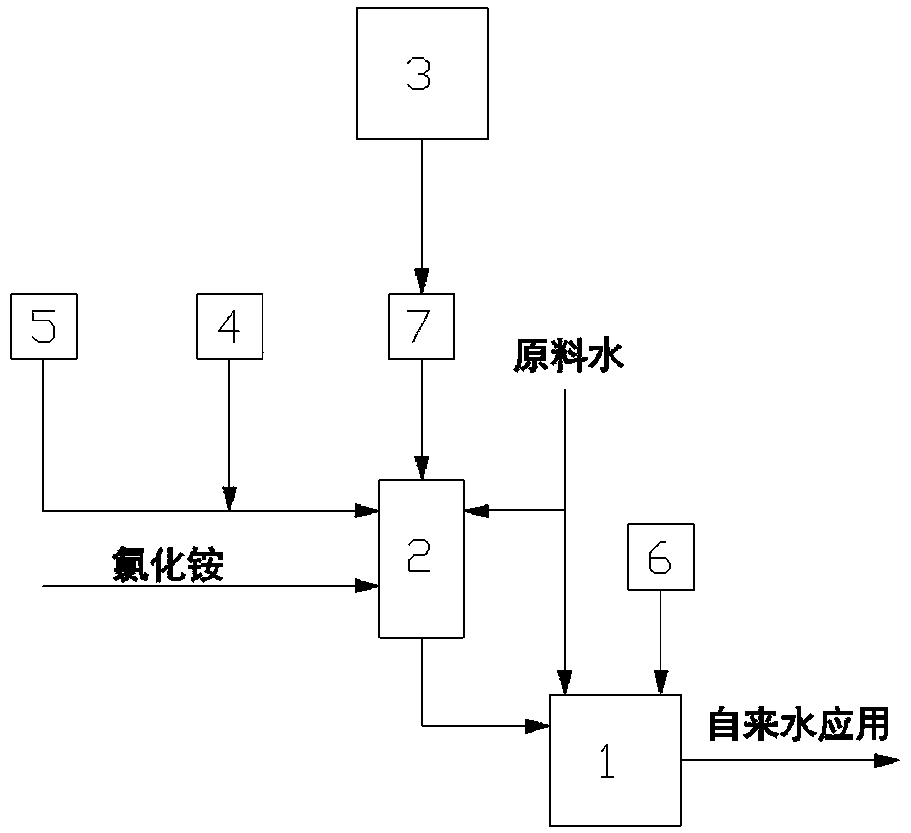

[0049] Measure 17 kg of raw material sodium hypochlorite and put it into sodium hypochlorite solution feeding metering tank 3 (hereinafter referred to as metering tank 3), and measure 240 kg of raw material water into metering tank 3 through a metering pump; the concentration of sodium hypochlorite in metering tank 3 is 0.7% based on NaClO, and the total solution is 257 Kilogram. Measure 1.3 kg of ammonium chloride powder and put it into reactor 2; at the same time, use a metering pump to measure 85 kg of raw water into reactor 2; simultaneously use liquid level metering to measure 2 kg of 5% HCl from hydrochloric acid solution feeding metering tank 4 into the reactor 2; In reactor 2, the concentration of ammonium chloride is 1.465%, the total amount of the solution is 88.3 kg, and the pH value is 2.2. Quickly add 147 kg of 0.7% NaClO to the reactor 2 within 2 minutes to raise the pH value of the reaction solution to 8.9, and then use a pump to meter 150 kg of raw water to the...

Embodiment 2

[0051] Measure 17 kilograms of raw material sodium hypochlorite and put it into metering tank 3, and metering pump measures 240 kilograms of raw material water into metering tank 3; the concentration of sodium hypochlorite in metering tank 3 is 0.7% based on NaClO, and the total solution is 257 kilograms. Measure 1.3 kg of ammonium chloride powder and put it into reactor 2; at the same time, use a metering pump to measure 88 kg of raw water into reactor 2; simultaneously use liquid level metering to measure 2.5 kg of 5% HCl from hydrochloric acid solution feeding metering tank 4 into the reactor 2; In reactor 2, the concentration of ammonium chloride is 1.41%, the total amount of the solution is 91.8 kg, and the pH value is 1.64. Quickly add 206 kg of 0.7% NaClO to the reactor 2 within 2 minutes to raise the pH value of the reaction solution to 8.9, and then use a pump to meter 150 kg of raw material water to the reactor 2. While opening the slower speed and continuously addin...

Embodiment 3

[0053] Measure 17 kilograms of raw material sodium hypochlorite and put it into metering tank 3, and metering pump measures 240 kilograms of raw material water into metering tank 3; the concentration of sodium hypochlorite in metering tank 3 is 0.7% based on NaClO, and the total solution is 257 kilograms. Measure 1.3 kilograms of powder ammonium chloride and put it into reactor 2; at the same time, measure 88 kilograms of raw water into reactor 2 with a metering pump; simultaneously measure 4 kilograms of 5% mixed acid into reactor 2 with a liquid level metering method, and the mixed acid is 5 %HCl and 5% H 3 PO 4 Mixed at a weight ratio of 1:1; in reactor 2, the concentration of ammonium chloride is 1.39%, the total amount of the solution is 93.3 kg, and the pH value is 2.16. Quickly add 188 kg of 0.7% NaClO to Reactor 2 within 2 minutes to raise the pH value of the reaction solution to 8.9, and then use a pump to meter 150 kg of raw material water to Reactor 2. While conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com