Preparation method of heavy alkylbenzene heat conduction oil

A technology of heavy alkyl benzene and heat transfer oil, which is applied in the field of preparation of heavy alkyl benzene heat transfer oil, can solve the problems of pipeline blockage, high energy consumption, low heat transfer efficiency, etc., and achieves the advantages of preventing pipeline blockage and increasing heat transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

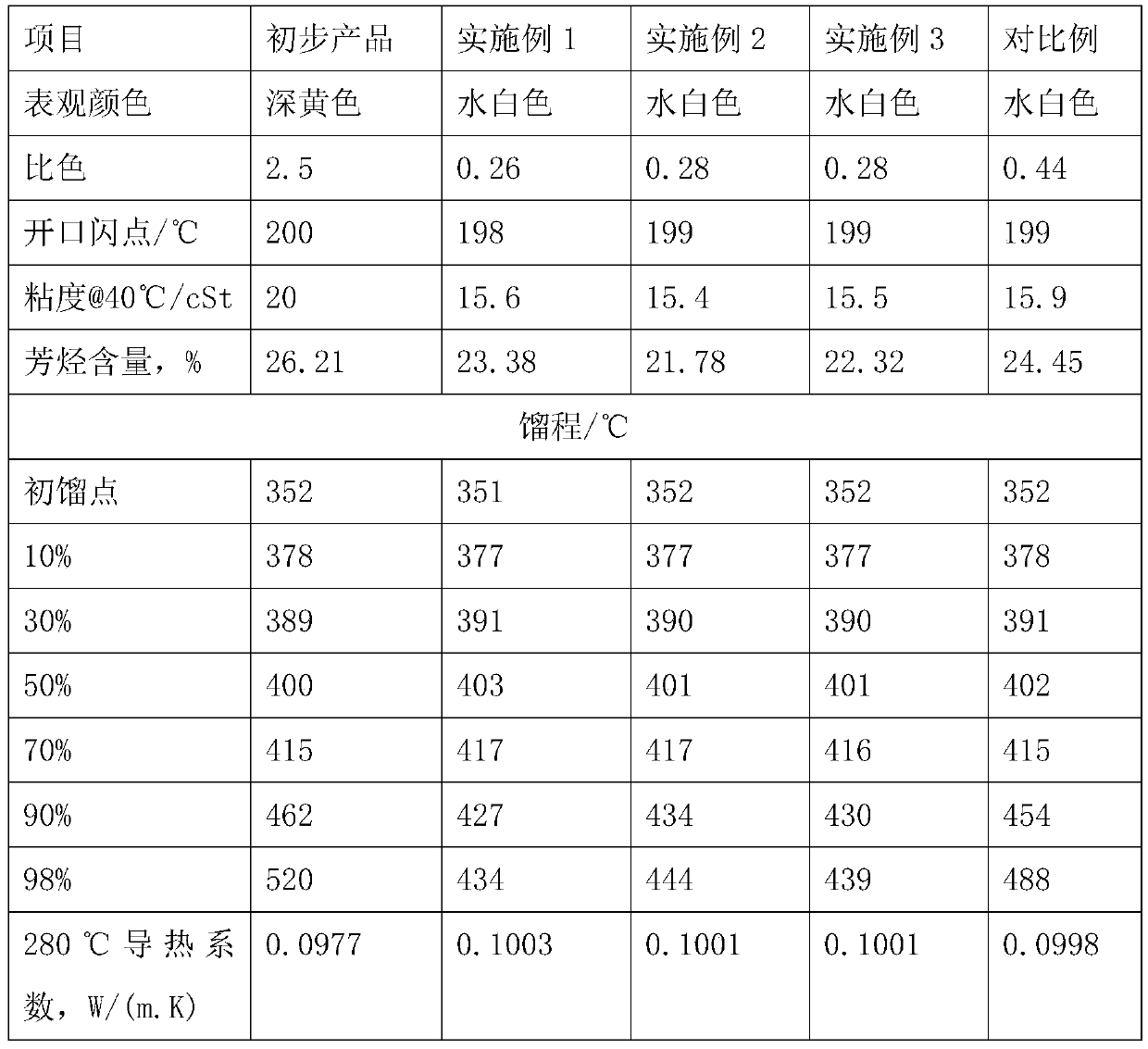

[0017] After the chromatographic analysis of the preliminary product adopted in this embodiment, the content of each component is determined as follows: monoalkylbenzene: 18.5%; dialkylbenzene: 59.8%; diphenylalkane: 5.9%; polyphenylalkane: 7.8% ; Dialkylindanes: 3.7%; Dialkyltetralins: 3.3%; Unknown components: 1%.

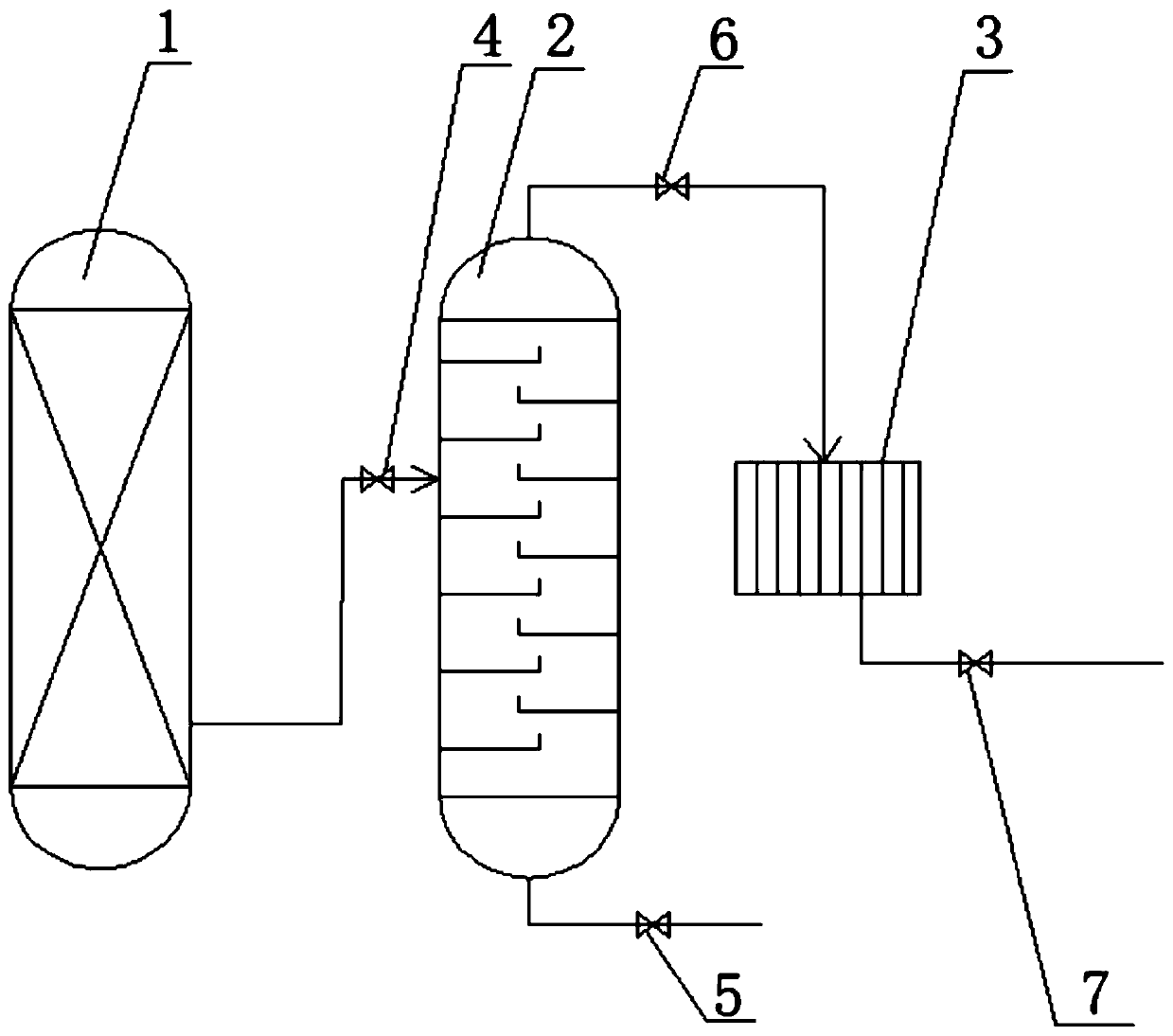

[0018] The preliminary product of this embodiment is in the original product reactor 1, and the original product reactor 1 is connected to the vacuum distillation tower 2 through the first valve 4; the second valve 5 is set at the bottom of the vacuum distillation tower 2, and the tower top passes through The third valve 6 is connected to the cooler 3; the fourth valve 7 is set behind the cooler 3; in the initial state, the first to fourth valves 7 are all in a closed state;

[0019] The operation process includes:

[0020] A, open the first valve 4 after vacuum distillation tower 2 pressure is reduced to 6.7kPa negative pressure, because vacuum distillation tow...

Embodiment 2

[0024] This embodiment adopts the same preliminary product as in Example 1, and the same reaction system. The difference from Example 1 is only that the vacuum distillation conditions are set to 300° C. and 6.0 kPa.

Embodiment 3

[0026] This embodiment adopts the same preliminary product as in Example 1, and the same reaction system. The difference from Example 1 is only that the vacuum distillation conditions are set to 330° C. and 7.0 kPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com