Design method of diffractive optical element with high diffraction efficiency and low speckle noise

A diffractive optical element and diffraction efficiency technology, applied in the design field of diffractive optical elements, can solve the problems of serious speckle noise, low diffraction efficiency, quantization error, etc., and achieve low speckle noise, high diffraction efficiency, and suppression of quantization error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The protection scope of the present invention should include all content of the claims. Through the following examples, those skilled in the art can realize all the contents of the claims of the present invention.

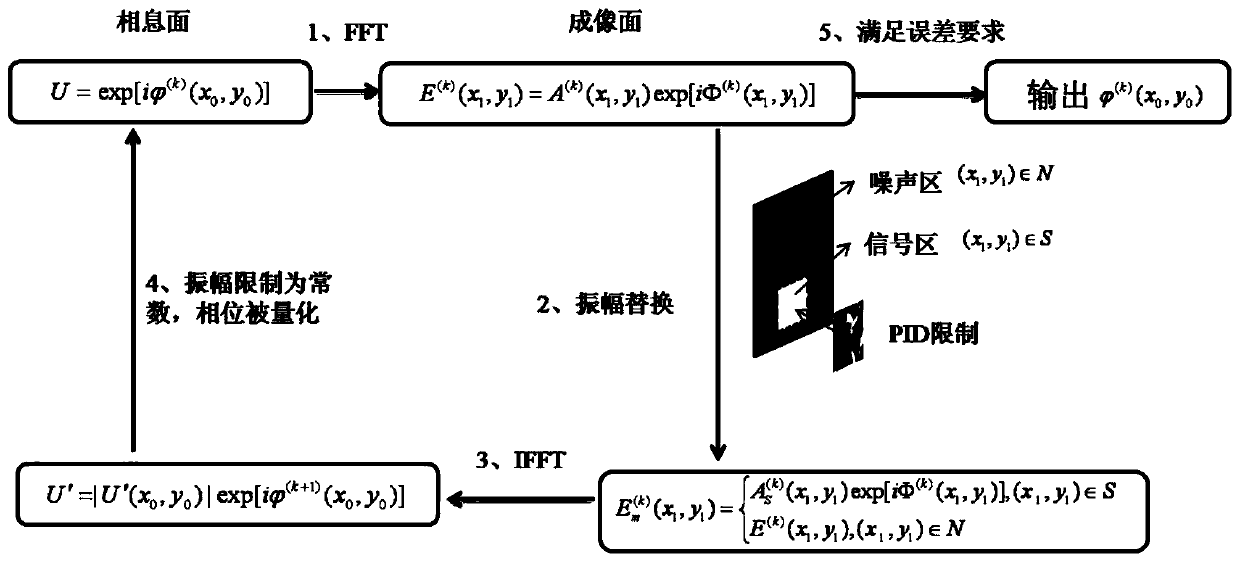

[0047] figure 1 Flowchart for the design of diffractive optical elements with high diffraction efficiency and low speckle noise, such as figure 1 Shown, the design method step of the present invention is as follows:

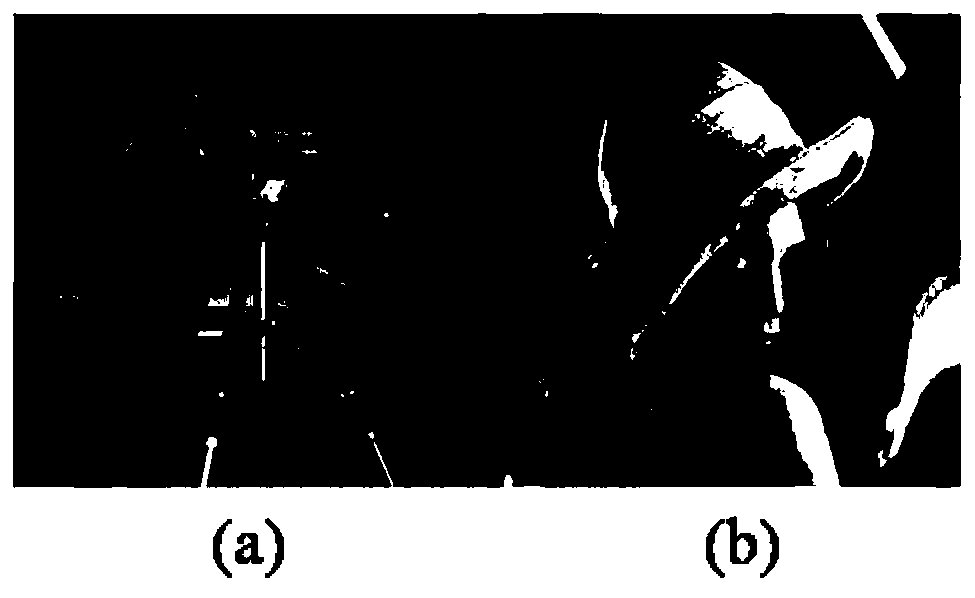

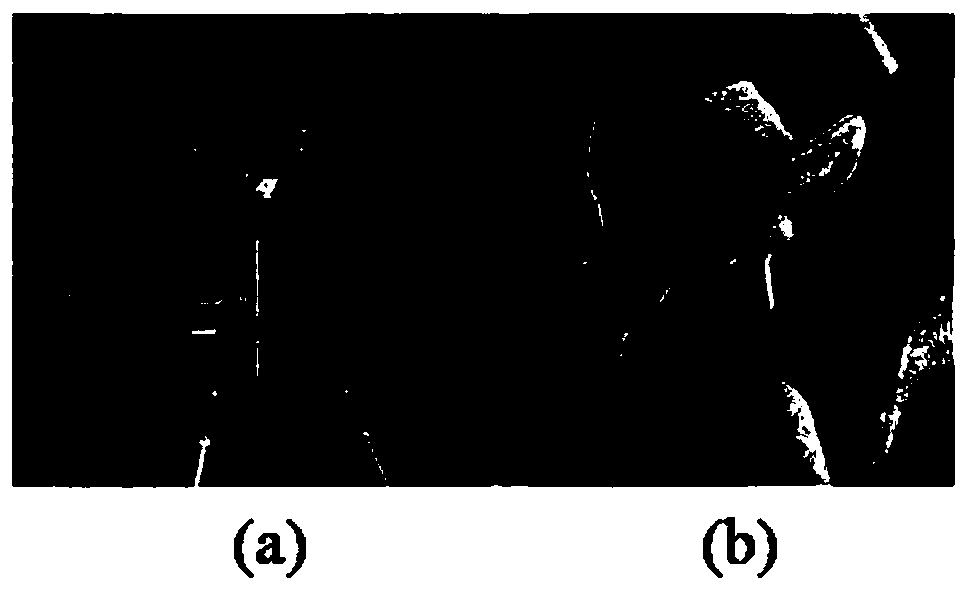

[0048] Step (1), the wavelength of the laser used in the diffraction element design is a plane wave of λ=650nm, select figure 2 (a) and (b) as the light intensity distribution I of the target light field d (x 1 ,y 1 ), where the target light field amplitude distribution

[0049] Step (2), using Fast Fourier Transform FFT as the diffraction propagation function;

[0050] Step (3), the number of phase steps of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com