Production method of TiN-S and TiO2-S composite material with hollow nanosphere structure

A technology of hollow nano and composite materials, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of capacity attenuation, limit the initial capacity value of the battery, and poor conductivity, so as to increase the initial specific capacity, inhibit dissolution, and improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

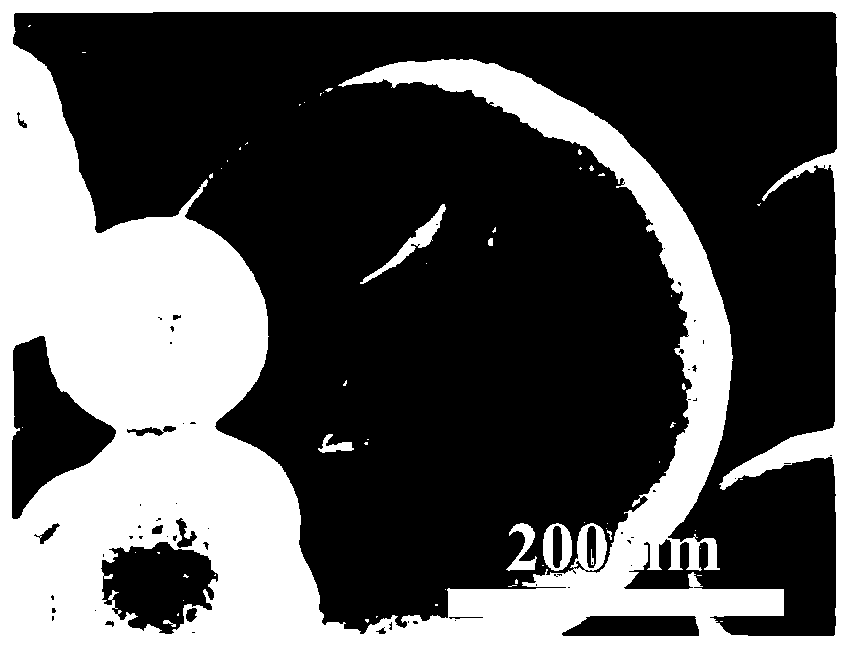

[0029] Embodiment 1, the preparation method of the TiN-S composite material of hollow nanosphere structure, comprises the following steps:

[0030] (1) Dissolve 2g of HDA in 100ml of KCl solution (0.1m / L) and stir for 20min, then add 7-10ml of titanium isopropyl (TIP) dropwise under electromagnetic stirring;

[0031] (2) Then add 0.7ml of ammonia to the mixture prepared in step (1), and incubate at 160° C. for 20 to 30 hours, and wash the precipitated product with ethanol;

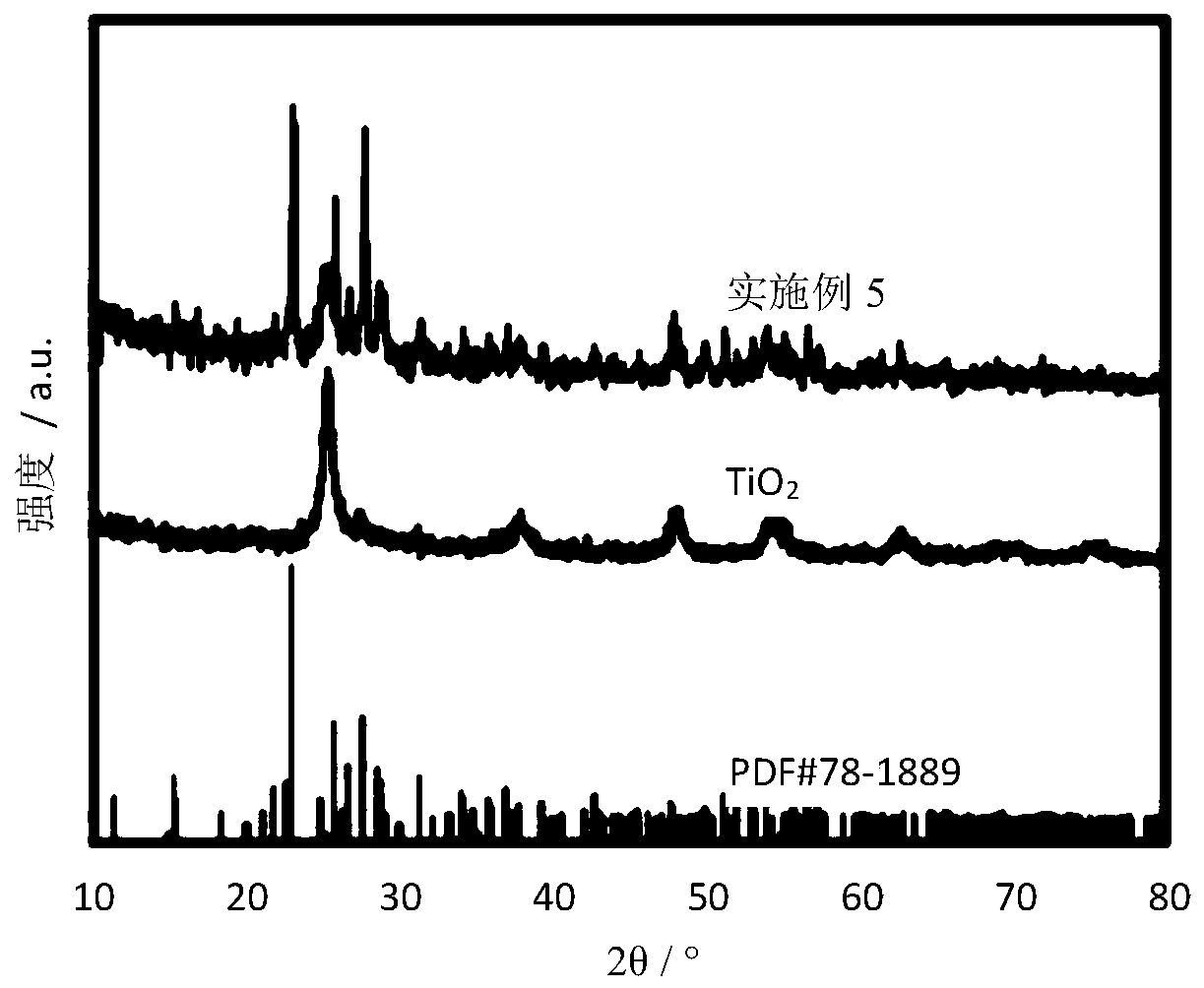

[0032] (3) Transfer the precipitated product washed in step (2) to a muffle furnace and keep it at 580°C for 3 hours to obtain TiO 2 hollow nanospheres;

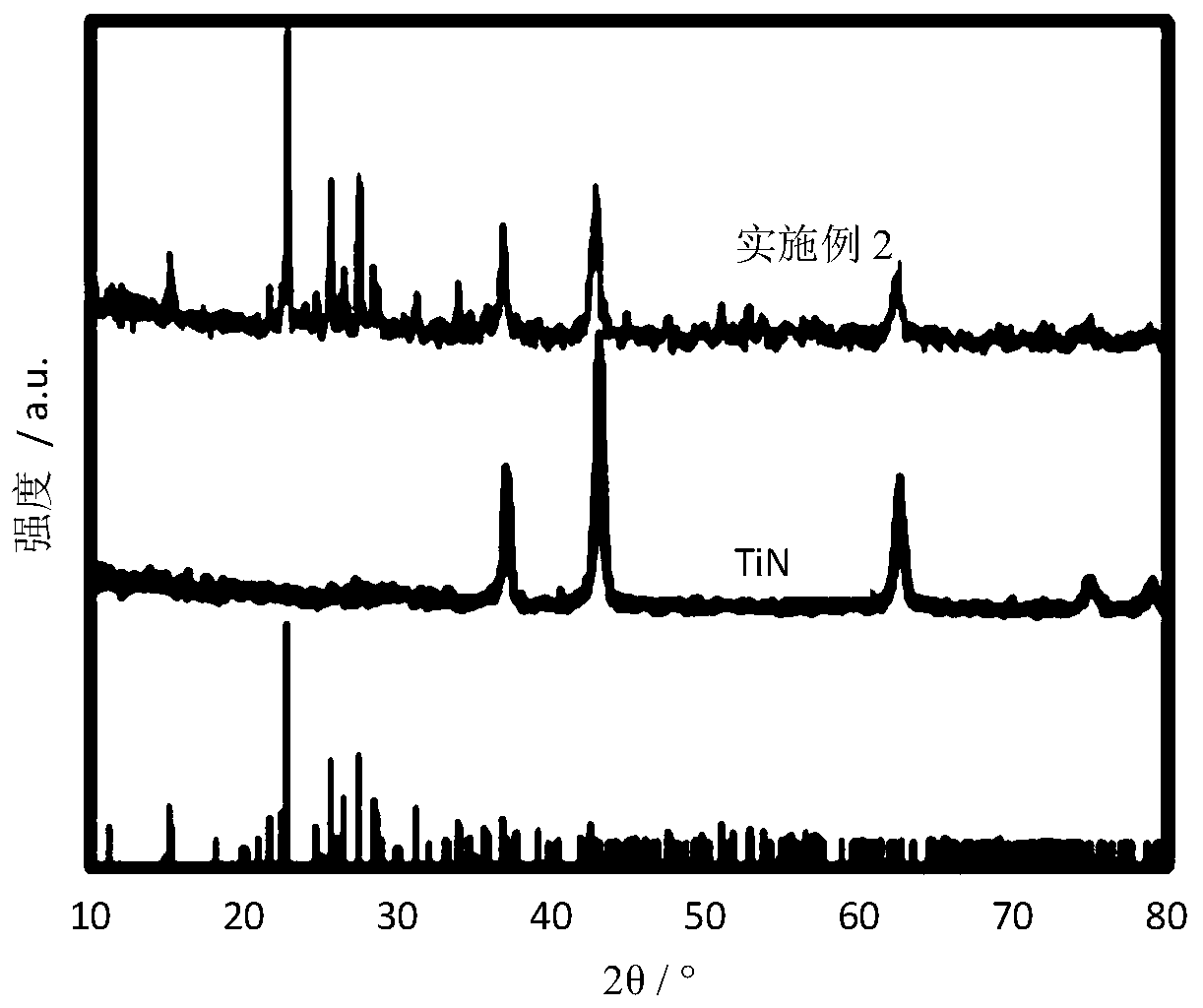

[0033] (4) in NH 3 Under the atmosphere, the TiO prepared in step (3) 2 Hollow nanospheres were further incubated at 900°C for 2 hours to prepare TiN composites;

[0034] (5) Mix the TiN composite material prepared in step (4) with sulfur at a mass ratio of 1:3, then transfer it to a tube furnace, and heat the mixture to 155 °C for 12 h under a nitro...

Embodiment 2

[0035] Embodiment 2, the preparation method of the TiN-S composite material of hollow nanosphere structure, comprises the following steps:

[0036] (1) Dissolve 3g of HDA in 100ml of KCl solution (0.3m / L) and stir for 40min, then add 10ml of titanium isopropyl (TIP) dropwise under electromagnetic stirring;

[0037] (2) Then add 0.9ml of ammonia to the mixture prepared in step (1), and incubate at 160°C for 30h, and wash the precipitated product with ethanol;

[0038] (3) Transfer the precipitated product washed in step (2) to a muffle furnace and keep it at 580°C for 5 hours to obtain TiO 2 hollow nanospheres;

[0039] (4) in NH 3 Under the atmosphere, the TiO prepared in step (3) 2 Hollow nanospheres were further incubated at 900°C for 4 hours to prepare TiN composites;

[0040] (5) Mix the TiN composite material prepared in step (4) with sulfur at a mass ratio of 1:4, then transfer it to a tube furnace, heat the mixture to 155°C for 14h under a nitrogen atmosphere, and p...

Embodiment 3

[0041] Embodiment 3, the preparation method of the TiN-S composite material of hollow nanosphere structure, comprises the following steps:

[0042] (1) Dissolve 3g of HDA in 100ml of KCl solution (0.2m / L) and stir for 30min, then add 8ml of titanium isopropyl (TIP) dropwise under electromagnetic stirring;

[0043] (2) Then add 0.8ml of ammonia to the mixture prepared in step (1), and incubate at 160°C for 15h, and wash the precipitated product with ethanol;

[0044] (3) Transfer the precipitated product washed in step (2) to a muffle furnace and keep it at 580°C for 4 hours to obtain TiO 2 hollow nanospheres;

[0045] (4) in NH 3 Under the atmosphere, the TiO prepared in step (3) 2 Hollow nanospheres were further incubated at 900°C for 3 hours to prepare TiN composites;

[0046] (5) Mix the TiN composite material prepared in step (4) with sulfur at a mass ratio of 1:3, then transfer it to a tube furnace, and heat the mixture to 155 °C for 13 h under a nitrogen atmosphere t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com