A silicon oxide/carbon composite nanowire negative electrode material, preparation method and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in the field of electrochemistry, can solve the problems of limited electrical conductivity and low volume expansion rate, and achieve the effects of delaying pulverization and buffering volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

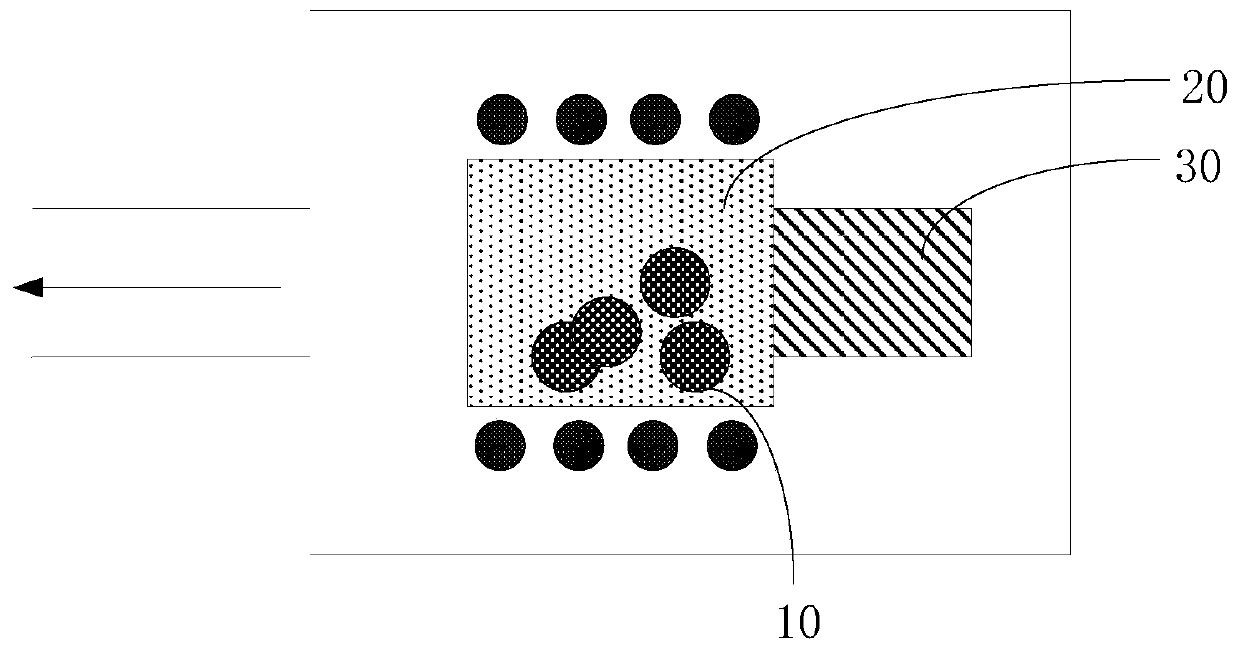

[0043] The present invention also provides a method for preparing a silicon oxide / carbon composite nanowire negative electrode material, the method comprising:

[0044] Step S101, providing SiOx nanowire material.

[0045] Specifically, after mixing silicon and silicon dioxide in a predetermined mass ratio, they are heated to a predetermined temperature in a high vacuum environment to grow SiOx nanowire materials;

[0046] SiOx nanowire materials with a predetermined diameter range are screened out, and the screened SiOx nanowire materials are granulated or spheroidized to obtain SiOx nanowire particles with a predetermined particle size distribution range.

[0047] Wherein, the mass ratio of silicon and silicon dioxide is 0.8-1.2:2, such as 0.8:2, 1:2, 1.2:2; the temperature range for growing SiOx nanowire materials is 1000-1400°C, and the holding time range is 2- 30h, the diameter range of the grown SiOx nanowire material is 5-200nm.

[0048] It can be understood that the ...

Embodiment 1

[0069] The preparation method of SiOx nanowire material is as follows:

[0070] (1) Place 980 g of commercially purchased silicon powder raw materials and 2000 g of silicon micropowder raw materials in a VC mixer, mix at a speed of 998 rpm, and hold for 30 minutes to fully mix the two to obtain nanowire raw materials.

[0071] (2) Place 2980g of uniformly mixed raw materials in the reaction chamber of a horizontal vacuum furnace, and put a collector in the collection chamber; heat to 1350°C under vacuum conditions to make the nanowire raw materials react, and the gaseous products in the reaction process pass through rapidly. Condensation generates SiOx nanowire material, and the product is collected after the reaction.

[0072] (3) Observing the morphology and structure of the prepared nanowire material using a scanning electron microscope, the test results are as follows: Figure 4 shown by Figure 4 It can be seen that the diameter of the prepared nanowire material is unif...

Embodiment 2

[0074] The preparation method of silicon oxide / carbon composite nanowire negative electrode material is as follows:

[0075] (1) choose 4000g by the SiOx nanowire material that embodiment 1 makes, as Figure 5 As shown, the selected SiOx nanowire materials have uniform diameters, such as 54.4nm, 56.2nm, 59.6nm, and 60.5nm, and their average particle diameter D50 is controlled at about 4um after treatment.

[0076] (2) Put the above-mentioned 4um nanowire material in a vapor deposition furnace, that is, a CVD furnace. Nitrogen gas is passed into the outer path as a protective gas, and methane gas is passed into the inner path as a carbon source. Heating to 900°C makes the methane decompose and coat Agent carbon, the nitrogen flow rate is set to 3.5L / min during the reaction, and carbon is coated on the surface of the SiOx nanowire material and / or in the gap between the SiOx nanowire material, wherein the ratio of carbon to SiOx nanowire material is 27%.

[0077] (3) After the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com