CoO/rGO composite and preparation method and use thereof

A composite and purpose technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of limiting the practical application of lithium-air batteries, large difference in charge and discharge voltage, and short cycle life, and achieve green environmental protection. The effect of small overpotential and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) To prepare graphite oxide solution, dissolve 40mg of graphite oxide in 40ml of water, and sonicate in a cell pulverizer for 30min to obtain a uniform suspension.

[0042] (2) Add cobalt nitrate and urea at a molar ratio of 1:1 to the suspension, and stir at room temperature for 30 min.

[0043] (3) Transfer the homogeneous suspension (2) to a reaction kettle and heat at 120°C for 12 hours to obtain a precipitate.

[0044] (4) Wash the obtained precipitate three times with water and ethanol respectively, dry in an oven at 60°C to obtain a dry solid, and then grind the solid into a powder in a mortar.

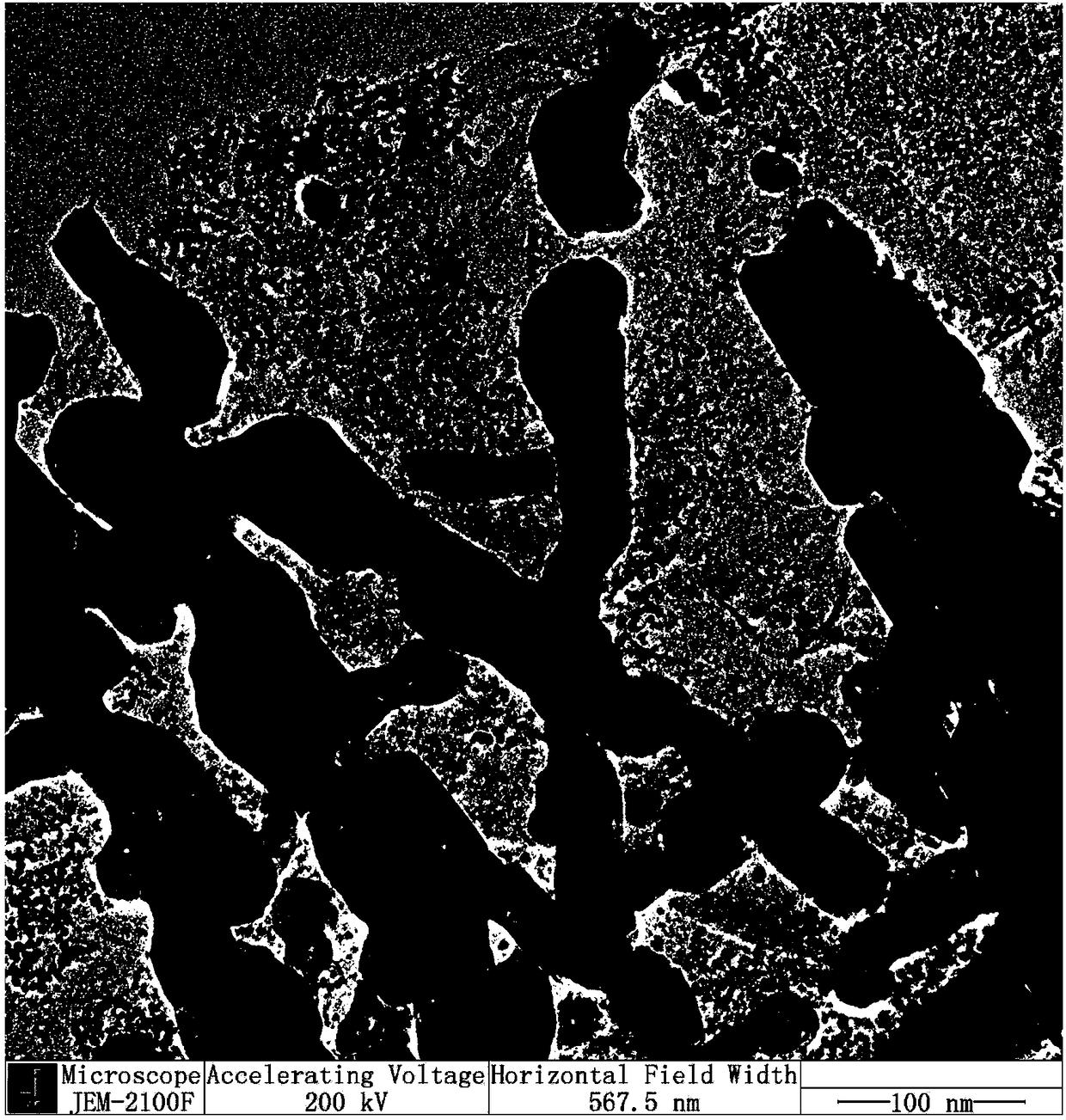

[0045] (5) The powder obtained in step (4) was calcined at 500°C for 4 hours under the protection of Ar atmosphere to obtain a CoO / rGO composite.

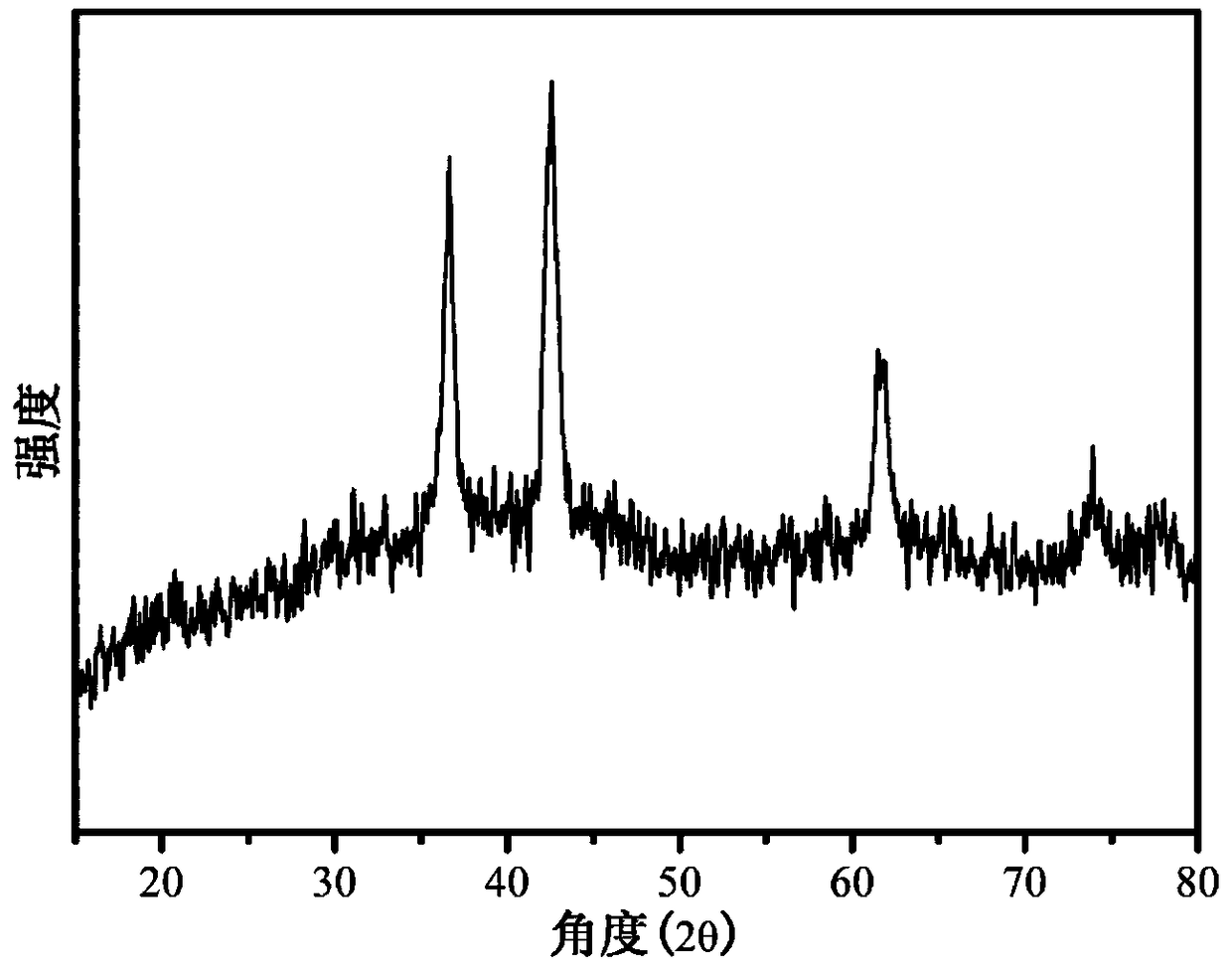

[0046] Such as figure 1 Shown is the XRD pattern of the CoO / rGO composite. The diffraction peaks are consistent with the standard peaks of cobalt oxide (JCPDS Card No. 48-1719), and there are no impurity peaks, indicating...

Embodiment 2

[0048] The CoO / rGO composite prepared in Example 1, PVDF and SP were mixed according to a mass ratio of 7:2:1 and ground in a mortar for half an hour to make them completely mixed. Then put the uniformly mixed solid powder into a small beaker, drop a few drops of N-methyl-2-pyrrolidone (NMP) and ultrasonicate for half an hour, so that the sample is evenly dissolved in the reagent. Finally, the dissolved product was evenly coated on carbon paper with a diameter of 1.2 cm, and dried in a vacuum oven at 120° C. for 12 hours to obtain a porous electrode containing the catalyst.

Embodiment 3

[0050] The catalyst-containing porous electrode prepared in Example 2, lithium sheet, PTFE separator, and electrolyte (1.0 M LiTFSI / TEGDME) were assembled into an air battery in an argon-filled glove box.

[0051] Lithium-air battery assembly sequence is from bottom to top, first place the negative electrode (lithium sheet) in the center of the mold base, drop two drops of electrolyte, then put a layer of PTFE diaphragm, then drop two drops of electrolyte on the diaphragm, and then put the positive electrode The sheet is placed on the separator (the side coated with the positive electrode material is placed facing the separator), and finally the mold is screwed tightly, placed in an oxygen-filled environment, and the electrochemical test is performed after standing for 5 hours.

[0052] Such as Figure 4 As shown, the composite catalyst was applied to Li-air batteries, at 100 mA g -1 The charge and discharge test was carried out under the current density, and the discharge ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com