A method for simultaneously preparing rare ginseng saponins and oil unsaponifiables

A technology for rare saponins and saponins of ginseng, which is applied in pharmaceutical formulations, plant raw materials, medical preparations containing active ingredients, etc., can solve the problems of not seeing oil unsaponifiables and ginsenosides, cumbersome operations, waste of manpower and material resources, etc. , to achieve the effect of large development value, simplified operation and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

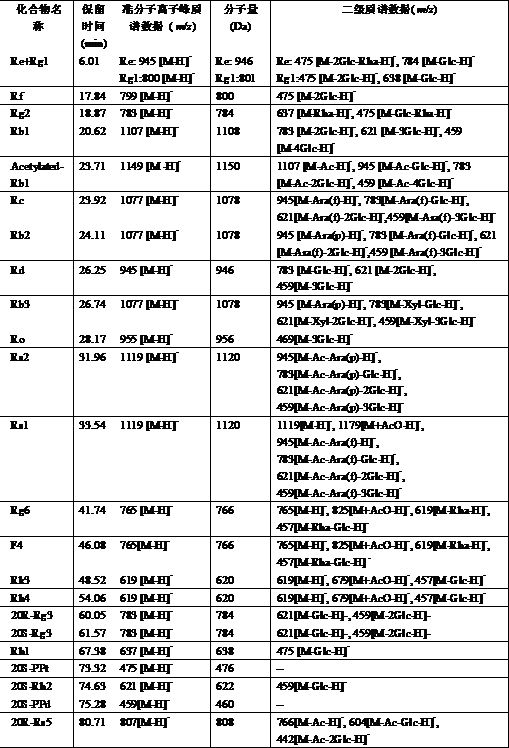

[0032] Process the dried ginseng into powder, take 5g, add 50mL petroleum ether, 1.0g sodium hydroxide, 25mL n-butanol, 50mL ethanol, 50mL water, extract with a stirring tank or a stirrer, the stirring shaft speed: 120 rpm, The temperature is: 140 degrees Celsius, the heating time is 0.5 hours, after the heating is completed, let it stand for 90 minutes, take the upper layer solution, and concentrate under reduced pressure or normal pressure to obtain the unsaponifiable matter of ginseng oil. Take the solution in the lower layer, concentrate it to 1 / 4 of the original volume, add 2.5g of macroporous resin, the type of macroporous resin is D101, first elute with water until the ethanol eluent is colorless, clear and transparent, with a pH value of 7, Then elute with ethanol solution with a volume ratio of 40%, until the ethanol eluate is colorless, clear and transparent, collect the ethanol eluate, recover ethanol, and dry to obtain rare ginseng saponins in the form of dry extrac...

Embodiment 2

[0049] Process dried ginseng into powder, take 5g, add 100 mL petroleum ether, 1.5 g sodium hydroxide, 50 mL n-butanol, 80 mL ethanol, 150 mL water, extract with a stirring tank or a stirrer, stirring shaft speed: 140 rpm, temperature: 120°C, heating time: 1.0 hour, after heating, let stand for 150 min, take the upper layer solution, concentrate under reduced pressure or normal pressure, and obtain ginseng oil unsaponifiable matter. Take the solution in the lower layer, concentrate to 1 / 5 of the original volume, add 5.0 g of macroporous resin, the type of macroporous resin is D130, first elute with water until the ethanol eluent is colorless, clear and transparent, and the pH value is 7, Then elute with ethanol solution with a volume ratio of 50%, until the ethanol eluate is colorless, clear and transparent, collect the ethanol eluate, recover ethanol, and dry to obtain rare ginseng saponins in the form of dry extract.

Embodiment 3

[0051] Process dried ginseng into powder, take 5g, add 150 mL of petroleum ether, 2.0 g of sodium hydroxide, 80 mL of n-butanol, 150 mL of ethanol, 250 mL of water, use a stirring tank or a stirrer for extraction, stirring shaft speed: 160 rpm, temperature: 105°C, heating time: 1.5 hours, after heating, let it stand for 120 minutes, take the upper layer solution, concentrate under reduced pressure or normal pressure, and obtain ginseng oil unsaponifiable matter. Take the lower layer solution, concentrate to 1 / 6 of the original volume, add 6.0 g macroporous resin, the type of macroporous resin is AB8, first elute with water until the ethanol eluent is colorless, clear and transparent, and the pH value is 7, Then elute with ethanol solution with a volume ratio of 50%, until the ethanol eluate is colorless, clear and transparent, collect the ethanol eluate, recover ethanol, and dry to obtain rare ginseng saponins in the form of dry extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com