Bionic nanofiltration membrane for extracting humic acid from landfill leachate membrane concentrate and preparation method of bionic nanofiltration membrane

A technology for landfill leachate and membrane concentration, applied in the field of nanofiltration membranes, can solve the problems of bionic layer roughness, long reaction time, deposition difficulties, etc., and achieve the effects of excellent anti-pollution performance, simple deposition method and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A biomimetic nanofiltration membrane for extracting humic acid in landfill leachate membrane concentrate, its preparation method comprises the following steps:

[0024] 1) Dissolving polyethyleneimine and persulfate in Tris hydrochloride buffer solution, and adjusting the pH to 8.5; then adding dopamine hydrochloride, and mixing thoroughly to obtain a membrane modification solution; the membrane The concentration of dopamine hydrochloride in the modified solution is 1.06×10 -2 mol / L, the concentration of polyethyleneimine is 6.7×10 -3 mol / L, the concentration of persulfate is 8.7×10 -3 mol / L.

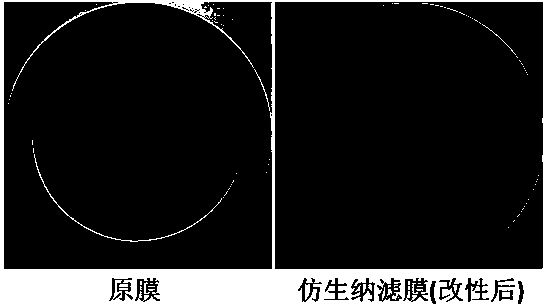

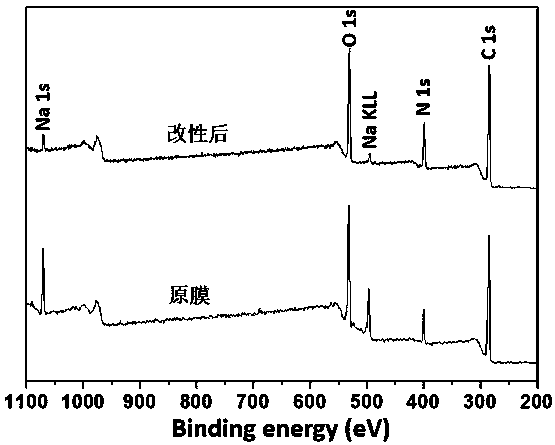

[0025] 2) Fix the basement membrane with a molecular weight cut-off of 640 Da in the device for interfacial reaction; pour the membrane modification solution to make it fully contact with the surface of the basement membrane and carry out the deposition reaction; after 2 h, the modified basement membrane The membrane is taken out and cleaned to obtain a biomimetic nanofiltra...

Embodiment 2

[0028] A biomimetic nanofiltration membrane for extracting humic acid in landfill leachate membrane concentrate, its preparation method comprises the following steps:

[0029] 1) Dissolving polyethyleneimine and periodate in tris hydrochloride buffer solution, and adjusting the pH to 8.5; adding dopamine hydrochloride, and mixing thoroughly to obtain a membrane modification solution; The concentration of dopamine hydrochloride in the membrane modification solution is 1.06×10 -2 mol / L, the concentration of polyethyleneimine is 5.3×10 -3 mol / L, the concentration of periodate is 7.1×10 -3 mol / L.

[0030] 2) Fix the basement membrane with a molecular weight cut-off of 890 Da in the device for interfacial reaction; pour the membrane modification solution to make it fully contact with the surface of the basement membrane and carry out the deposition reaction; after 10 h, the modified basement membrane The membrane is taken out and cleaned to obtain a biomimetic nanofiltration m...

Embodiment 3

[0033] A biomimetic nanofiltration membrane for extracting humic acid in landfill leachate membrane concentrate, its preparation method comprises the following steps:

[0034] 1) Dissolving polyethyleneimine and Fenton's reagent in Tris hydrochloride buffer solution, and adjusting the pH to 8.5; then adding dopamine hydrochloride, and mixing thoroughly to obtain a membrane modification solution; the membrane The concentration of dopamine hydrochloride in the modified solution is 1.06×10 -2 mol / L, the concentration of polyethyleneimine is 7.9×10 -3 mol / L, the concentration of Fenton's reagent is 1.06×10 -2 mol / L.

[0035] 2) Fix the basement membrane with a molecular weight cut-off of 1280 Da in the device for interfacial reaction; pour the membrane modification solution to make it fully contact with the surface of the basement membrane and carry out the deposition reaction; after 16 h, place the modified basement membrane The membrane is taken out and cleaned to obtain a ...

PUM

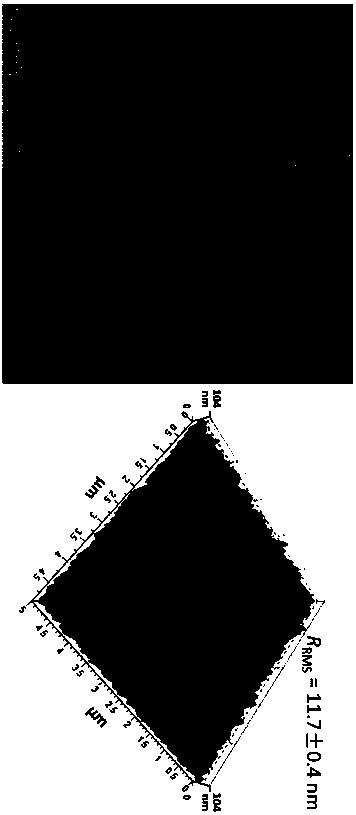

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com