Uniform weld joint welding device

A welding device and uniform technology, applied in welding equipment, welding accessories, electrode support devices, etc., can solve the problems of poor weld controllability and achieve the effects of increasing deposition rate, improving thermal efficiency, and improving control flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following is further described in detail through specific implementation methods:

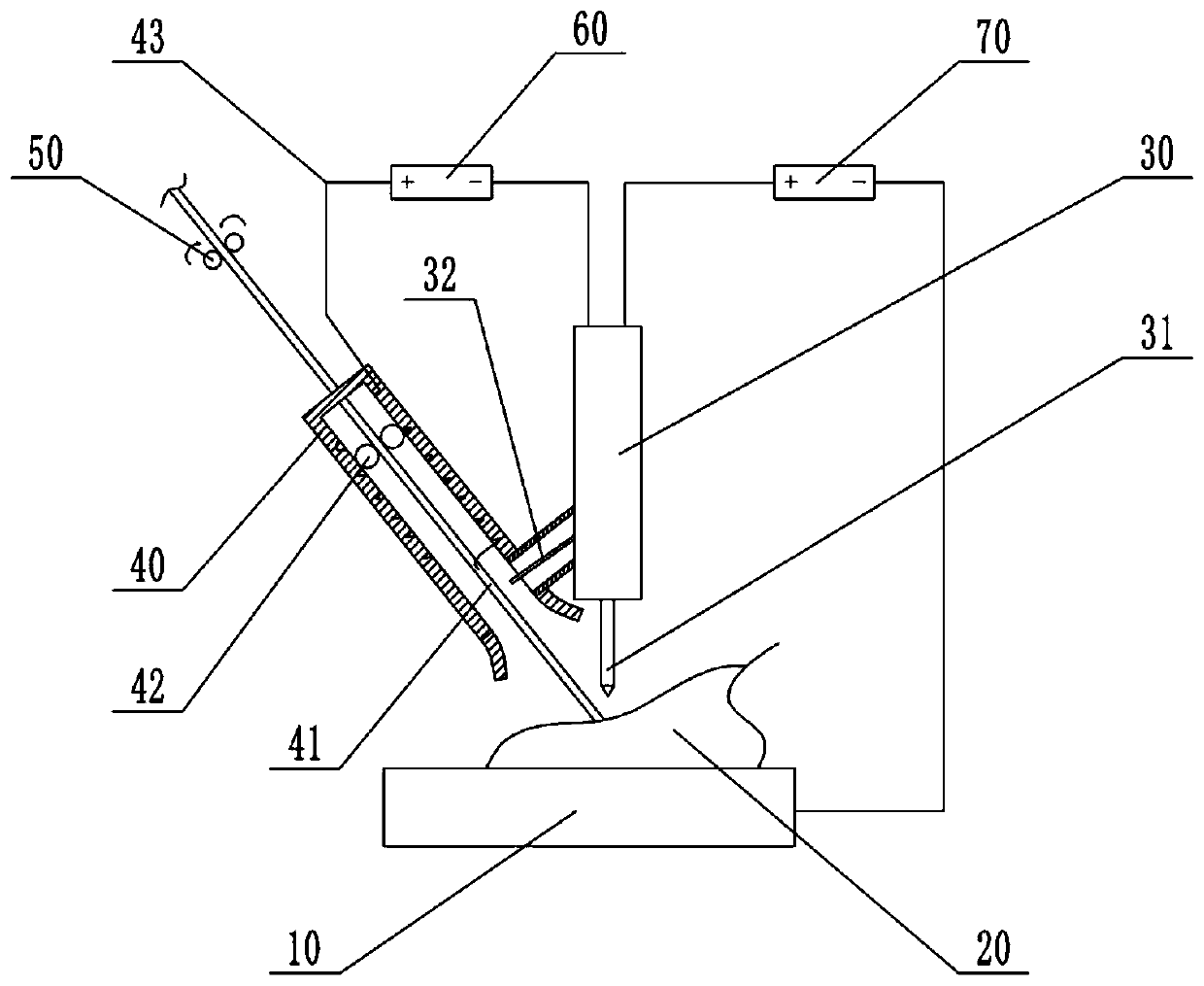

[0017] The reference signs in the drawings of the description include: base material 10, molten pool 20, tungsten welding gun 30, main tungsten wire 31, branch tungsten wire 32, welding wire welding gun 40, welding wire 41, guide wheel 42, coil 43, wire feeding mechanism 50 , the second power source 60 , and the first power source 70 .

[0018] The embodiment is basically as attached figure 1 Shown: a uniform seam welding device, the base material 10 molten pool 20 is at the bottom. On the upper left of the base material 10 is a welding wire welding torch 40, which is installed obliquely on the frame, and above the welding torch is a wire feeding mechanism 50, and the wire feeding mechanism 50 can be a traditional machine feeding mechanism. On the upper right of the base material 10 is the tungsten electrode welding torch 30 , and on the upper right are the first power source 70 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com