Graphene oxide paper with surface microsphere structure and preparation method thereof

A graphene paper, graphene ball technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as limited application fields, difficult to control graphene oxide paper, etc., achieve high specific surface area, wide The effect of applying potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

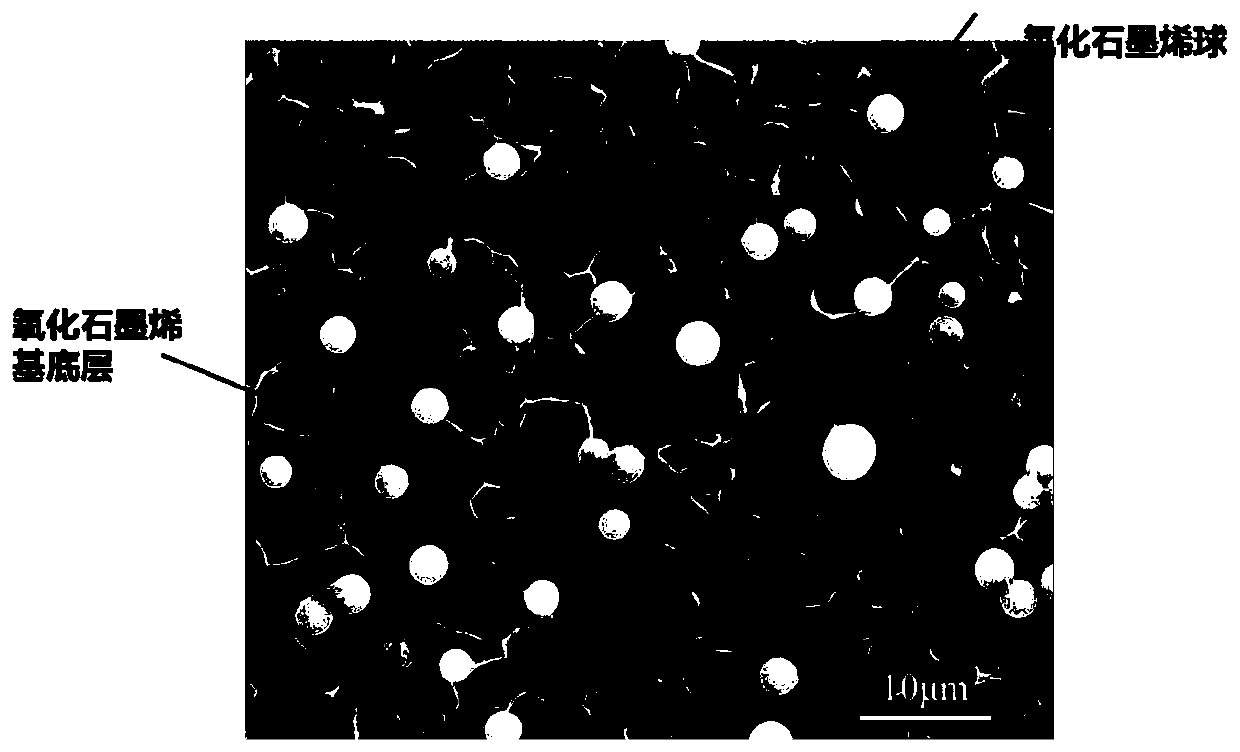

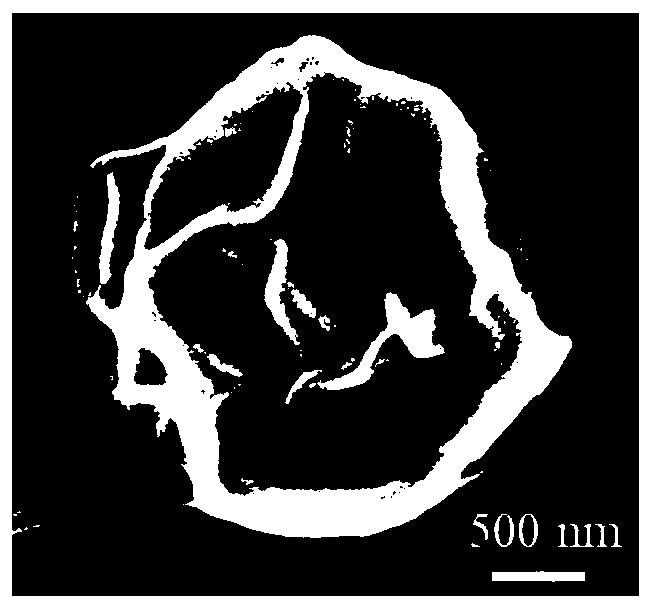

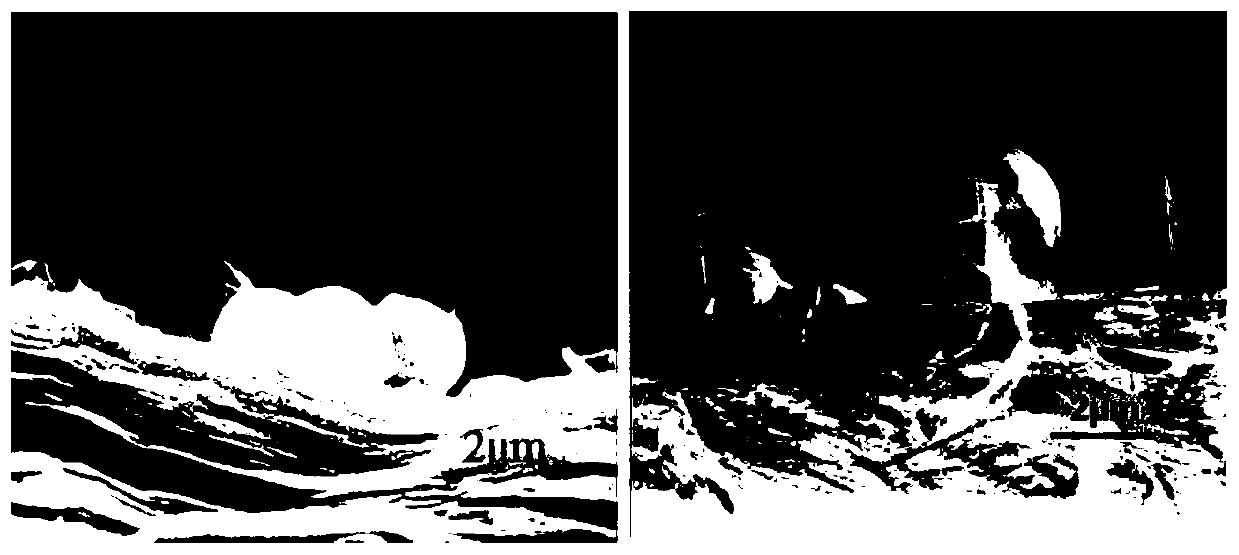

[0025] Specific embodiment one: what this embodiment records is a kind of graphene oxide paper with surface microsphere structure, and the upper surface of described graphene oxide paper is uniformly distributed with micron-scale graphene oxide balls, and the surface microscopic appearance is as follows figure 1 As shown, the microscopic morphology of graphene oxide spheres is as follows figure 2 As shown, and the bottom of the graphene oxide sphere and the graphene oxide paper below it are closely connected by graphene sheets, the microscopic appearance of the material section is as follows image 3 As shown, the interior of the graphene oxide sphere is a hollow structure.

specific Embodiment approach 2

[0026] Embodiment 2: The graphene oxide paper having a surface microsphere structure described in Embodiment 1, wherein the particle size distribution of the graphene oxide spheres is 2.3 μm˜2.8 μm.

specific Embodiment approach 3

[0027] Specific embodiment three: a graphene oxide paper with a surface microsphere structure described in specific embodiment one, the bottom is composed of graphene oxide paper composed of stacked graphene sheets, the thickness is 50-80 μm, and the surface has wrinkles. Among them, the graphene paper does not contain a microsphere structure inside, and the structure diagram is as follows Figure 4 shown.

[0028] Specific embodiment four: a kind of graphene oxide paper with surface microsphere structure described in specific embodiment one, the material components are all formed by graphene oxide sheet self-assembly stacking, the X-ray photoelectron spectroscopy analysis of the material ( XPS) characterization data such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com