Chemical oxidation-photocatalysis combined device

A chemical oxidation and photocatalysis technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of complex and harsh water quality, difficult to meet the treatment requirements of high-salt and high-ammonia-nitrogen wastewater , to achieve the effect of convenient external connection, strong compatibility and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

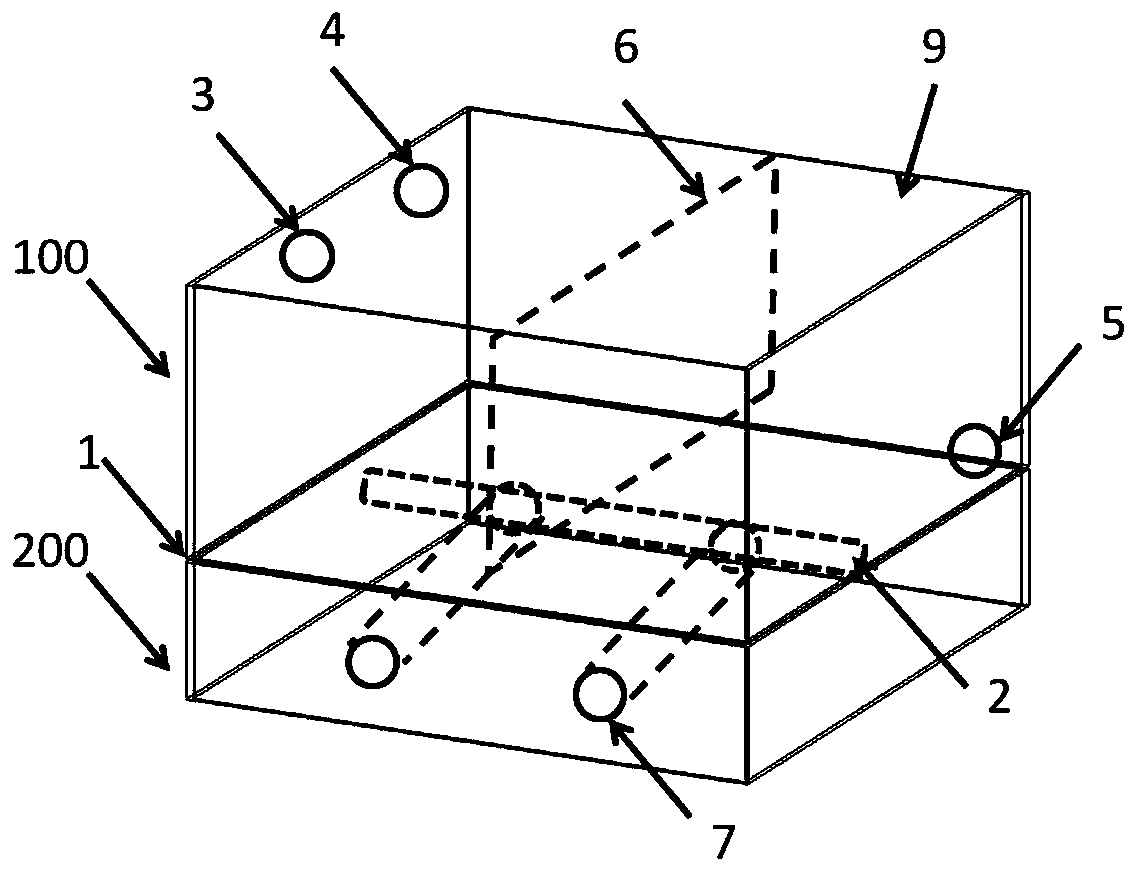

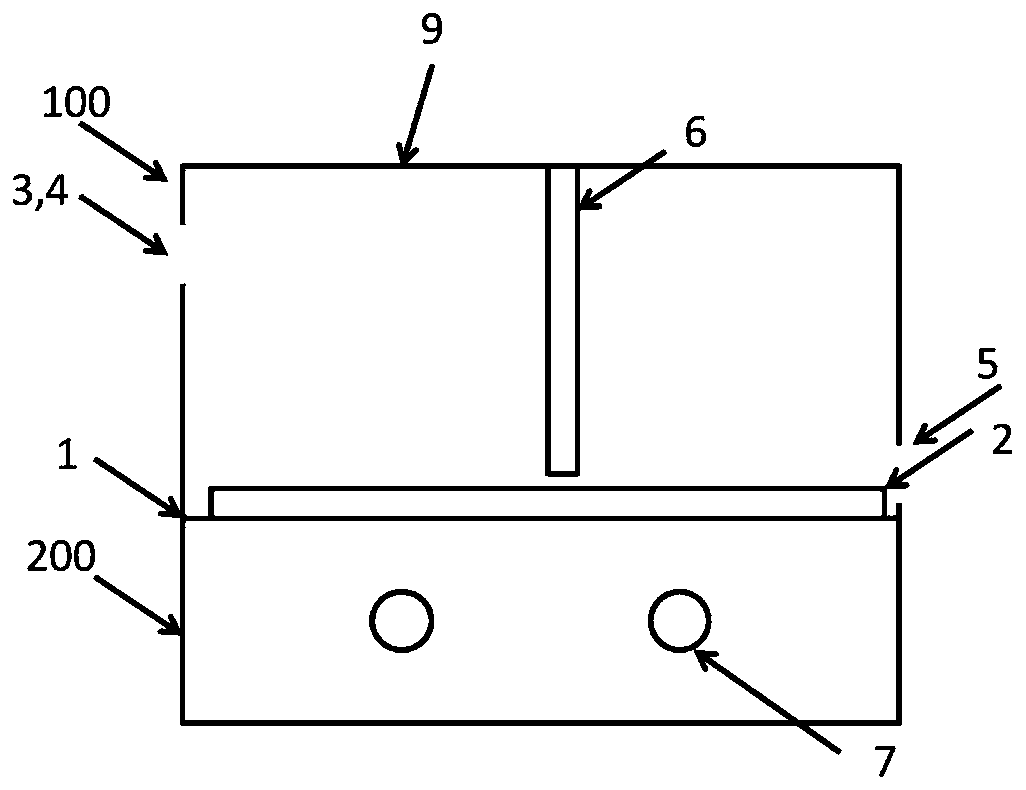

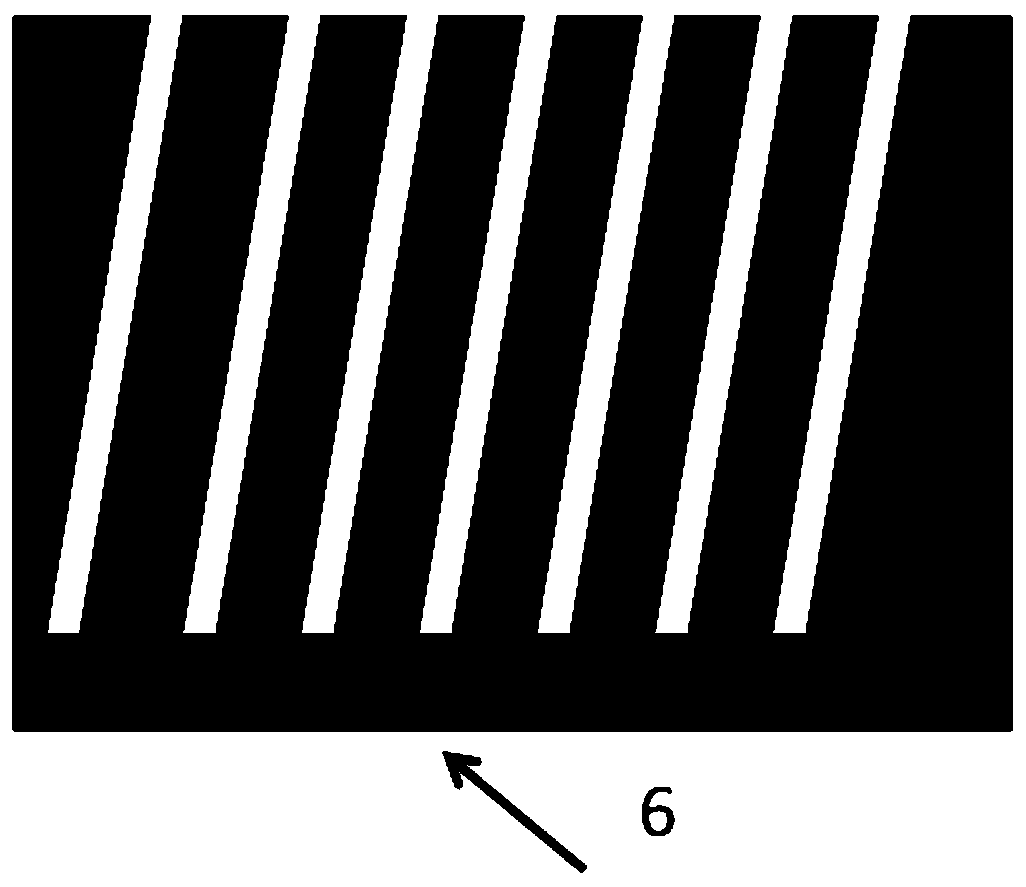

[0028] Such as Figure 1-3 As shown, the chemical oxidation-photocatalysis combined device includes a main box body, the main box body is mainly composed of a light-transmitting reaction space 100 and a light-tight light source space 200, and the two spaces are composed of a light-transmitting partition 1 separated. The aeration device 2 is laid on the bottom of the reaction space 100, which is beneficial to the mass transfer reaction. A liquid inlet 3 , a drug inlet 4 and a liquid outlet 5 are opened on the side of the reaction space 100 , and a jagged catalyst carrier 6 is placed in the reaction space 100 for directional arrangement of the immobilized catalyst. An artificial light source 7 is arranged in the light source space 200 .

[0029] Described main box body comprises box cover 9 and box body, and box cover 9 is arranged on the top of box body, and described box body and box cover 9 are separable.

[0030] The side and bottom of the opaque light source space 200 ar...

Embodiment 2

[0038] The structure of the chemical oxidation-photocatalysis combination device of embodiment 2 is basically the same as that of embodiment 1, the difference is that there is no case cover 9 on the main box, which is an open structure, and the catalyst carrier can be removed to facilitate powder The use of the catalyst and the external stirring device 8 realize the dispersion of the catalyst powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com