Hyperbranched organosilicon foam stabilizer and its preparation method and application

A foam stabilizer and organosilicon technology, which is applied in the field of hyperbranched silicone foam stabilizer and its preparation, and achieves the effects of good compatibility, wide density and practicability, excellent and stable foam stabilization and emulsification and foam stabilization effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

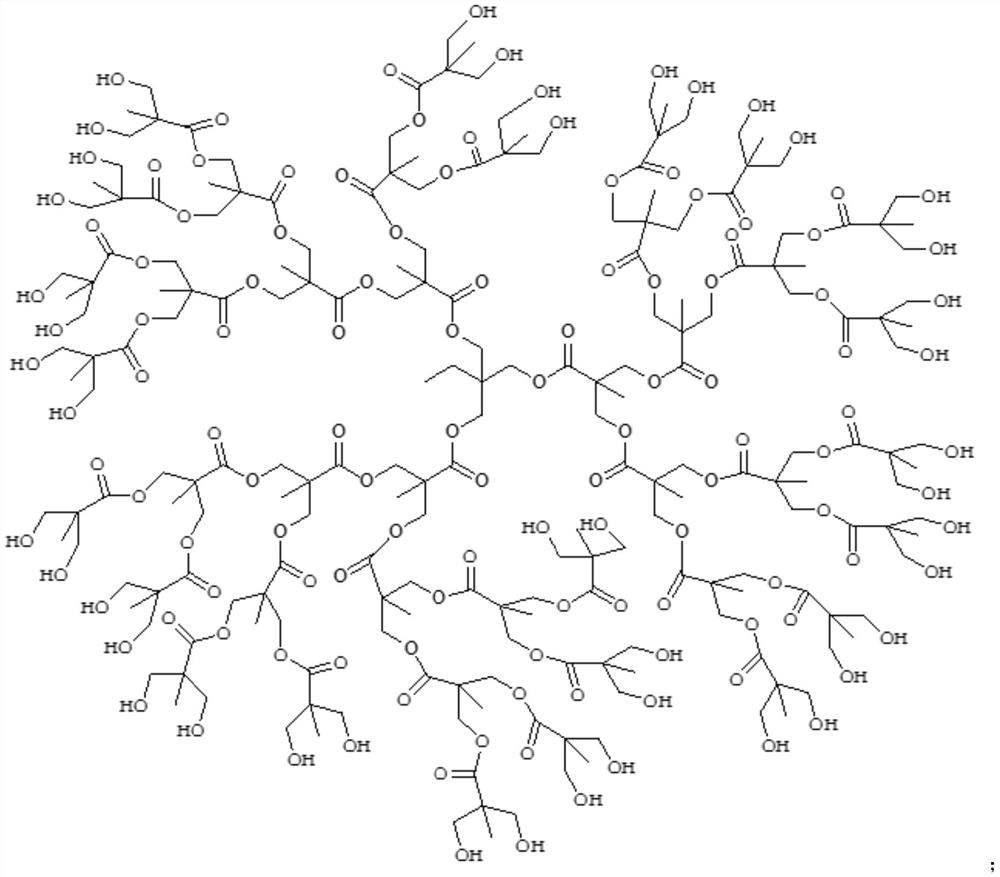

[0051] The preparation method of the hyperbranched organosilicon foam stabilizer provided in the embodiment of the present invention comprises:

[0052] The alkoxy-terminated hyperbranched polysiloxane is reacted with a hydroxyl-terminated polyether to obtain a hyperbranched organosilicon foam stabilizer. The structural formula of the polysiloxane segment of the alkoxy-terminated hyperbranched polysiloxane for [(CH 3 ) 2 SiO] m [CH 3 C 6 H 5 SiO] n [CH 3 CH 2 CH 2 CF 3 SiO] P , where m, n and p are all integers, and m=8-40, n=0-12, p=0-6, 0≤(n+p) / (m+n+p)≤0.25, 0≤ p / (m+n+p)≤0.1.

[0053] The hyperbranched organosilicon foam stabilizer prepared by the method provided by the invention has controllable molecular structure of the hyperbranched segment, adjustable molecules, and high degree of polymerization; the foam stabilizer has good compatibility with the polyurethane matrix; It has excellent emulsification and foam stabilization effects, and can meet the requireme...

Embodiment 1

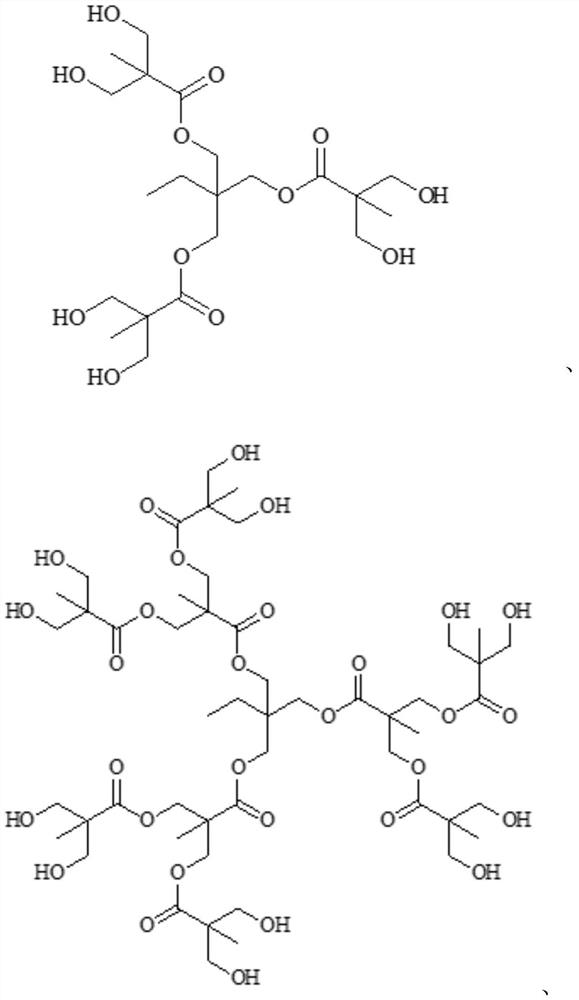

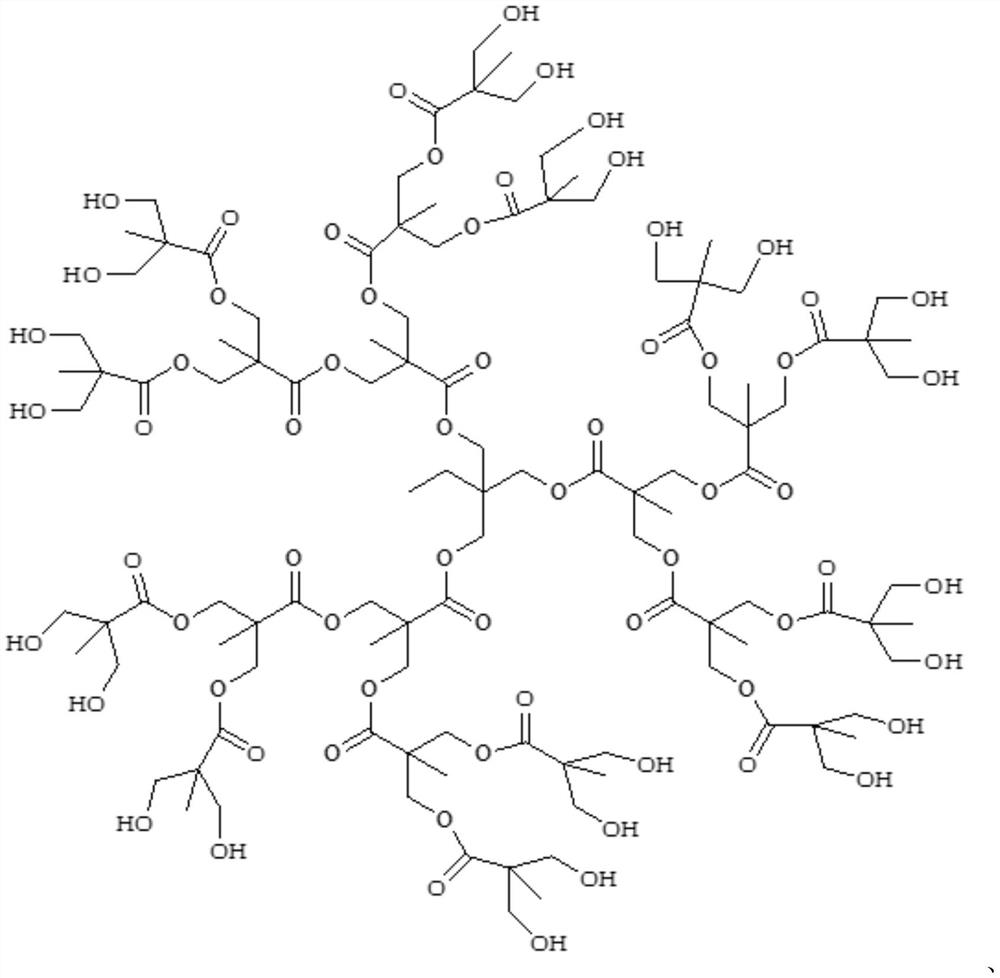

[0082] (1) Adopt "quasi one-step method", take 8.94g dimethylolpropionic acid as monomer, 2.98g trimethylolpropane as central nucleus, 0.04g p-toluenesulfonic acid as catalyst, under nitrogen protection, stir, Heated to 140°C for 0.5h reaction, then stopped nitrogen filling, decompressed to 400MPa and reacted for 2h, then added 17.88g dimethylolpropionic acid and 0.09g p-toluenesulfonic acid, reacted at 140°C for 0.5h under nitrogen protection, and then The pressure was reduced to 400-500MPa and reacted for 2h, cooled to room temperature, and the product was dissolved in acetone, then precipitated with n-hexane, filtered and vacuum-dried at 80°C / 400MPa for 24h to obtain 27.416g (yield 92.0%) of hydroxyl end Aliphatic hyperbranched polyester G2-HBPE;

[0083] (2) under nitrogen protection, put the obtained hydroxyl-terminated hyperbranched polyester G2-HBPE 3.14g into a three-necked flask, add 20.2ml (1.6mol / L) of n-hexane solution of tert-butyllithium under nitrogen atmosphere...

Embodiment 2

[0087] (1) Adopt "quasi one-step method", take 8.94g dimethylolpropionic acid as monomer, 2.98g trimethylolpropane as central nucleus, 0.04g p-toluenesulfonic acid as catalyst, under nitrogen protection, stir, Heated to 140℃ for 0.5h, then stopped nitrogen filling, decompressed to 500MPa and reacted for 2h, then added 17.88g dimethylolpropionic acid and 0.09g p-toluenesulfonic acid, under nitrogen protection, reacted at 140℃ for 0.5h, then The pressure was reduced to 400-500MPa and reacted for 2h, cooled to room temperature, and the product was dissolved in acetone, then precipitated with n-hexane, filtered and vacuum-dried at 80°C / 500MPa for 24h to obtain 27.416g (yield 92.0%) of hydroxyl end Aliphatic hyperbranched polyester G2-HBPE;

[0088] (2) under nitrogen protection, put the obtained hydroxyl-terminated hyperbranched polyester G2-HBPE 3.14g into a three-necked flask, add 22.2ml (1.6mol / L) n-hexane solution of n-butyllithium under nitrogen atmosphere, Aging at 90°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com