Preparation of flaky HZSM-5 molecular sieve catalyst and application of flaky HZSM-5 molecular sieve catalyst in preparation of aromatic hydrocarbon through carbon dioxide hydrogenation

A molecular sieve and catalyst technology, which is applied in the field of industrial catalytic material preparation and CO2 conversion and utilization, can solve the problems of thick molecular sieve thickness, etc., and achieve the effects of large total acid content, inhibition of carbon deposition rate, and good catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

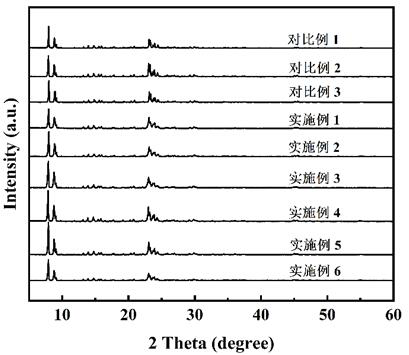

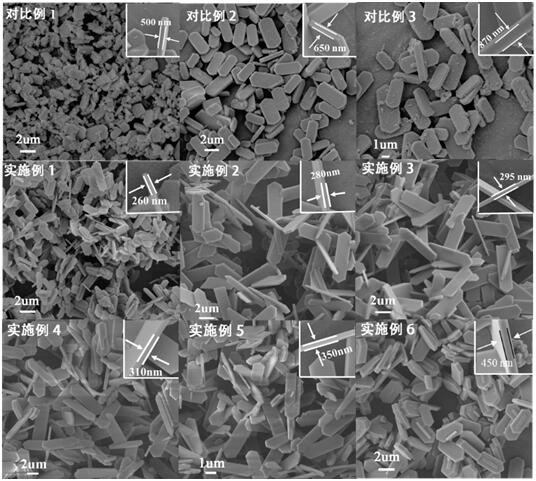

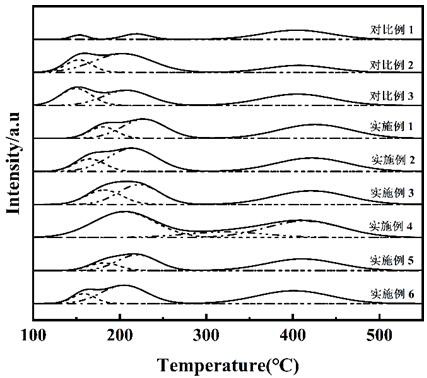

[0018] Preparation of Flake HZSM-5 Molecular Sieve: Raw Material Molar Ratio SiO 2 : Al 2 o 3 : TPAOH: Na 2 O: H 2 O: NH 4 F=1: 1 / 60: 0.4: 1 / 60: 35: 0.8. NaOH, C 9 h 21 AlO 3 , TPAOH and TEOS were added to deionized water, stirred at room temperature for pre-crystallization, and then stirred at 90 °C for 12 h. Then NH was added to the resulting mixed sol 4 F, and supplemented with volatile water, followed by vigorous stirring at 90°C for 12 h. Then the obtained solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, crystallized at 170 °C for 72 h, cooled to room temperature, centrifugally washed with deionized water until neutral, dried at 100 °C for 6 h, and 550 °C. Calcined at ℃ for 6 h to prepare sheet-like HZSM-5 molecular sieves.

[0019] The prepared flake HZSM-5 molecular sieve and ZnO-ZrO 2 Mix and grind at a mass ratio of 1:2 for CO 2 In the process of producing aromatics by hydrogenation (reaction pressure: 3.0 MPa, reacti...

Embodiment 2

[0021] Preparation of Flake HZSM-5 Molecular Sieve: Raw Material Molar Ratio SiO 2 : Al 2 o 3 : TPAOH: Na 2 O: H 2 O: NH 4 F=1: 1 / 60: 0.4: 1 / 60: 35: 1.5. NaOH, C 9 h 21 AlO 3 , TPAOH and TEOS were added to deionized water, stirred at room temperature for pre-crystallization, and then stirred at 90 °C for 12 h. Then NH was added to the resulting mixed sol 4 F, and supplemented with volatile water, stirred vigorously at 90°C for 12 h. Then the obtained solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, crystallized at 170 °C for 72 h, cooled to room temperature, centrifugally washed with deionized water until neutral, dried at 100 °C for 6 h, and roasted at 550 °C 6 h, the flake HZSM-5 molecular sieve was prepared.

[0022] The prepared flake HZSM-5 molecular sieve and ZnO-ZrO 2 Mix and grind at a mass ratio of 1:2 for CO 2 In the process of producing aromatics by hydrogenation (reaction pressure: 3.0 MPa, reaction temperature: 32...

Embodiment 3

[0024] Preparation of Flake HZSM-5 Molecular Sieve: Raw Material Molar Ratio SiO 2 : Al 2 o 3 : TPAOH: Na 2 O: H 2 O: NH 4 F=1: 1 / 60: 0.4: 1 / 60: 35: 2.6. Na 2 O, C 9 h 21 AlO 3 , TPAOH and TEOS were added to deionized water, stirred at room temperature for pre-crystallization, and then stirred at 90 °C for 12 h. Then NH was added to the resulting mixed sol 4 F, and supplemented with volatile water, stirred vigorously at 90°C for 12 h. Then the obtained solution was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, crystallized at 170 °C for 72 h, cooled to room temperature, centrifugally washed with deionized water until neutral, dried at 100 °C for 6 h, and roasted at 550 °C 6 h, the flake HZSM-5 molecular sieve was prepared.

[0025] The prepared flake HZSM-5 molecular sieve and ZnO-ZrO 2 Mix and grind at a mass ratio of 1:2 for CO 2 In the process of producing aromatics by hydrogenation (reaction pressure: 3.0 MPa, reaction temperature:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com