Up-conversion luminescence silicon dioxide aerogel and preparation method thereof

A technology of silica and aerogel, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of difficult PDMS uniform compounding, opacity, large size, etc., achieve uniform light transmission and display performance, safe, reliable and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The embodiment of the present invention carries out the preparation of up-conversion luminescent silica airgel, including the following steps:

[0062] (1) Add deionized water (5mL), NaOH aqueous solution (0.42mL, 5M), sodium citrate (0.3mL, 0.4M), yttrium acetate (1.56mL, 0.2M) into 20mL polytetrafluoroethylene liner in sequence , ytterbium acetate (0.4mL, 0.2M) and erbium acetate (0.04mL, 0.2M) and stirred at room temperature for 15min to obtain the first reaction solution;

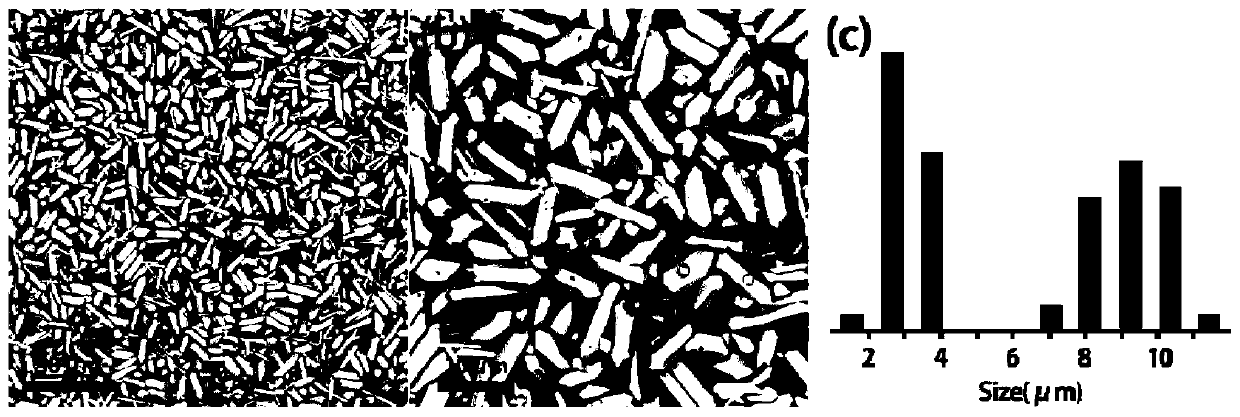

[0063] (2) Add ammonium fluoride aqueous solution (3.2mL, 2M) and hydrochloric acid solution (4mL, 1M) to the above-mentioned first reaction solution, continue to stir for 60min to obtain the second reaction solution, and then put the tetrafluoroethylene liner into the high-pressure reaction In the still, put it into an oven at 200° C. for heating reaction (crystal growth) for 20 hours to obtain the crystal material NaYF4:Yb / Er (20 / 2%).

[0064] (3) After the heating reaction, cool the reaction ...

Embodiment 2

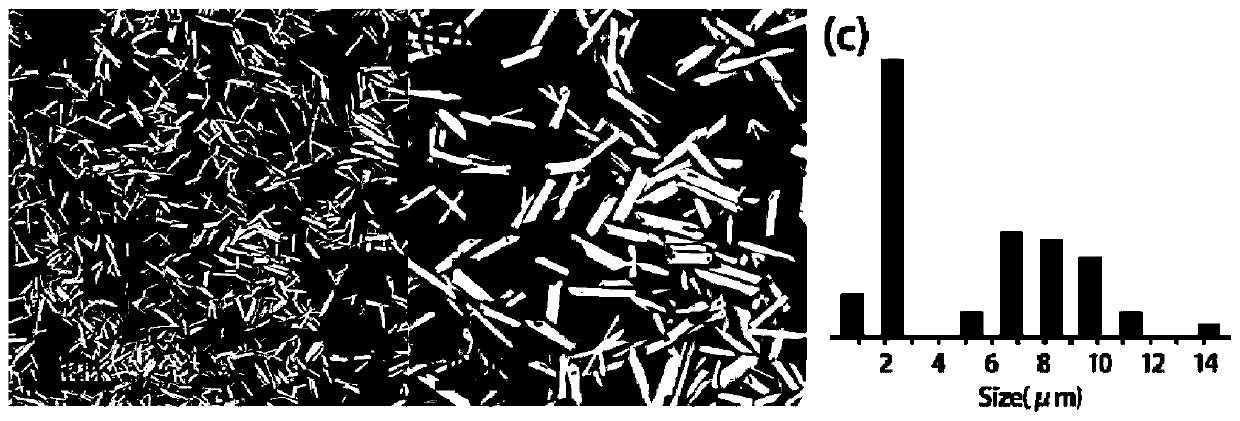

[0068] In this example, the preparation of upconversion luminescent silica airgel is carried out, and the steps are the same as in Example 1, the difference is that:

[0069] In step (1), the amount of sodium citrate is 0.5mL, that is, the molar ratio of sodium citrate to NaOH is 0.2:2.1, and the obtained crystal material sample is marked as Sample 2;

[0070] In step (5), the crystal material added is Sample 2, and up-conversion luminescent silica airgel 2 is obtained.

Embodiment 3

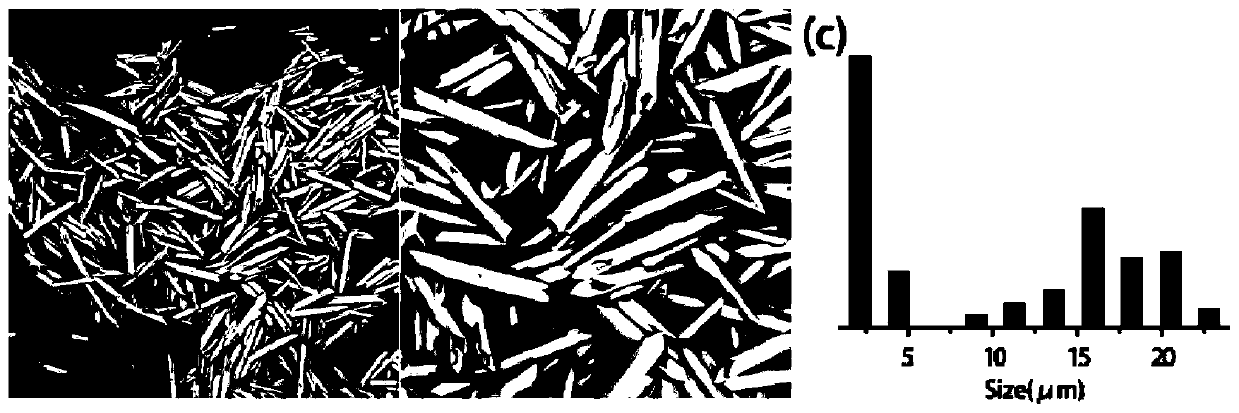

[0072] In this example, the preparation of upconversion luminescent silica airgel is carried out, and the steps are the same as in Example 1, the difference is that:

[0073] In step (1), the dosage of sodium citrate is 0.7 mL, that is, the molar ratio of sodium citrate to NaOH is 0.28:2.1, and the obtained crystal material sample is marked as Sample 3.

[0074] In step (5), the crystal material added is Sample 3, and up-conversion luminescent silica airgel 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com