Heavy alkylbenzene decolorization method

A heavy alkyl benzene, pre-decolorization technology, applied in the field of chemical decolorization, can solve the problems of difficult control of the reaction process, hydrodecolorization equipment and high energy consumption, etc., achieve good decolorization effect, high social value and ecological value, and easy decolorization effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

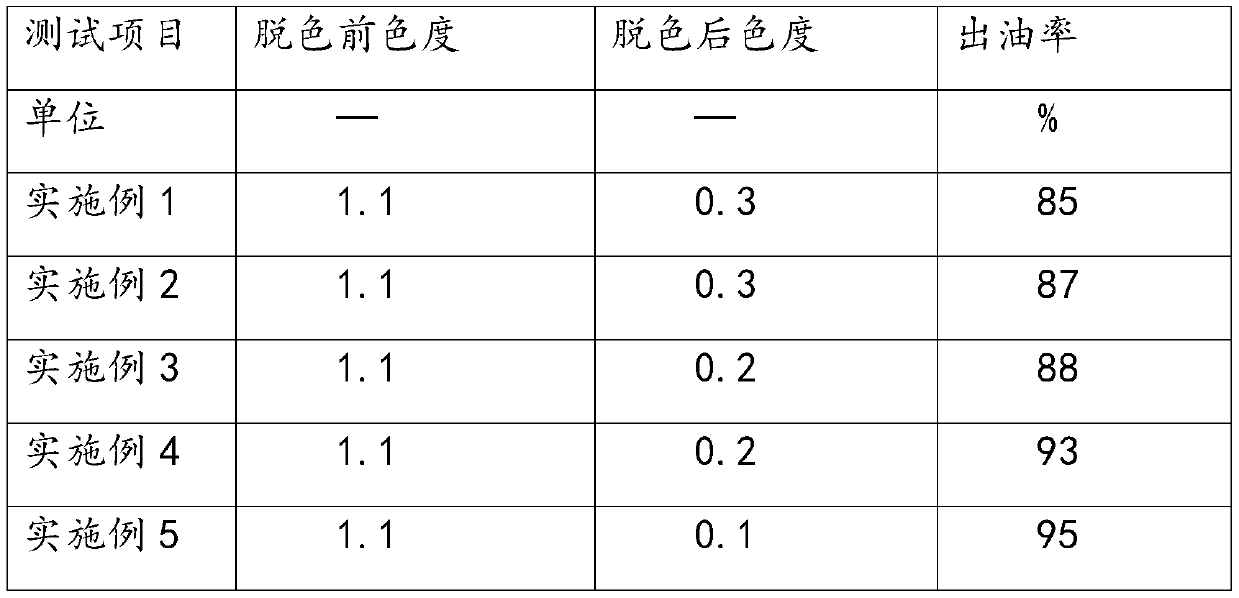

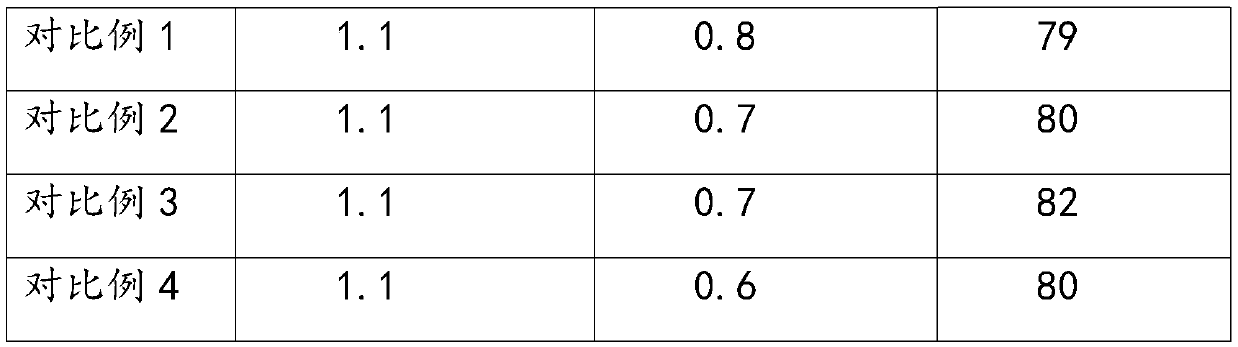

Examples

Embodiment 1

[0044] This example provides a kind of heavy alkyl benzene decolorization method, it is characterized in that, comprises the steps:

[0045] Step S1, pre-decolorization: mix the heavy alkylbenzene with the adsorbent evenly, decolorize at a certain stirring speed and temperature for 20 minutes, then ultrasonic decolorize for 10 minutes; then filter through a plate and frame filter press to obtain the pre-decolorization weight Alkylbenzene;

[0046] Step S2, secondary decolorization: the heavy alkylbenzene decolorized in step S1 is mixed with the decolorant, and microwave treatment is carried out while stirring, and the treatment time is 10 minutes;

[0047] Step S3, ion exchange resin decolorization: decolorize the heavy alkylbenzene after the second decolorization in step S3 through ion exchange resin;

[0048] Step S4, semi-chemical adsorption: decolorize the heavy alkylbenzene decolorized by the ion exchange resin in step S3 with polyamide, and obtain heavy alkylbenzene aft...

Embodiment 2

[0059] Example 2 provides a method for decolorizing heavy alkylbenzenes, which is basically the same as Example 1, except that the adsorbent includes the following components in parts by weight: 23 parts of clay, 12 parts of sepiolite powder, 6 parts of zeolite parts, 23 parts of activated carbon, 15 parts of diatomite, and 7 parts of basic alumina; the decolorizer includes the following components in parts by weight: 12 parts of superabsorbent resin, 33 parts of activated carbon, 17 parts of vermiculite, 12 parts of silica gel 6 parts, pulp 6 parts.

Embodiment 3

[0061] Example 3 provides a method for decolorizing heavy alkylbenzenes, which is basically the same as in Example 1, except that the adsorbent includes the following components in parts by weight: 25 parts of clay, 15 parts of sepiolite powder, 8 parts of zeolite parts, 25 parts of activated carbon, 20 parts of diatomite, and 8 parts of basic alumina; the decolorizer includes the following components in parts by weight: 15 parts of superabsorbent resin, 35 parts of activated carbon, 18 parts of vermiculite, 15 parts of silica gel 8 parts, 8 parts of pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com