Novel rice wine brewing process

A new type of rice wine, applied in the preparation of alcoholic beverages, methods based on microorganisms, microorganisms, etc., can solve the problems of insufficient taste and aroma, difficult quality control, and easily sour mash, and achieve good taste and control of fermentation power. , taste and wine quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

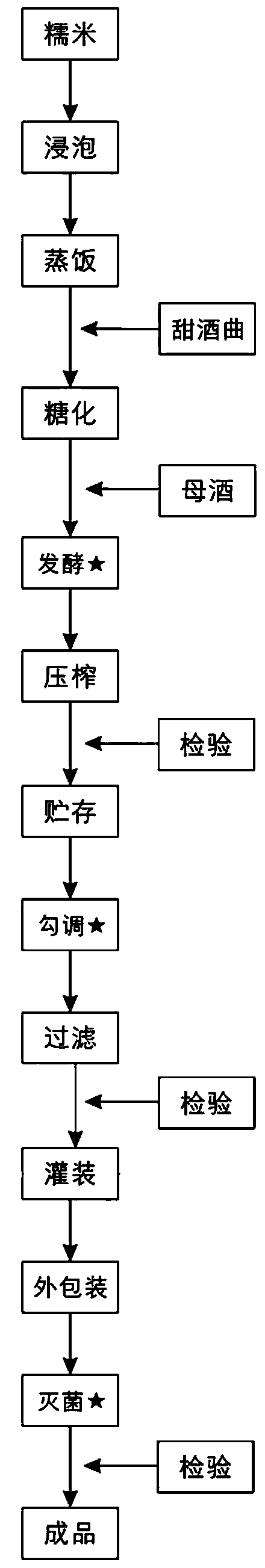

[0030] The new rice wine brewing process, the specific process is as follows figure 1 Shown, this novel rice wine brewing process comprises the steps:

[0031] (1) Rice soaking: Add room temperature water to the glutinous rice according to the mass ratio of glutinous rice: water = 1:1. The rice soaking water is 3cm higher than the highest rice level, and the rice soaking time is 10 hours.

[0032] (2) Steam rice: ①Put the soaked glutinous rice in a steamer to steam rice; ②Steam rice quality requirements: hard on the outside and soft on the inside, no white heart inside, loose and not mushy, transparent but not rotten, uniform, and the rice contains The water yield is 67%; 3. the cooked rice is regulated by adjusting the frequency converter of the air blower so that the temperature of the lower rice remains at 30°C to 32°C. The next koji ratio is 1% of the weight of the feed, and the added koji is sweet wine koji.

[0033](3) Saccharification: ①The steamed and broken up rice ...

Embodiment 2

[0041] The brewing process of novel rice wine comprises the steps:

[0042] (1) Rice soaking: add normal temperature water to the glutinous rice to soak the rice, and the rice soaking time is 20 hours.

[0043] (2) Steam rice: put the soaked glutinous rice in a steamer to steam the rice; adjust the temperature of the steamed rice so that the temperature of the lower koji is kept at 34°C to 37°C; the amount of the lower koji is 0.8% of the weight of the feed ; The added koji is sweet wine koji.

[0044] (3) Saccharification: pour the steamed and broken up rice into the mashing tank, spread the rice in the tank quickly and evenly, keep the rice loose in the tank, and form an inverted trumpet-shaped concave round nest; mashing After the mash is mature, add original wine to soak, the mass ratio of feeding amount to original wine is 1:1.5, and the added original wine is 55% vol rice-flavored original wine to obtain saccharified mash;

[0045] The temperature of the rice entering ...

Embodiment 3

[0051] The brewing process of novel rice wine comprises the steps:

[0052] (1) Rice soaking: add normal temperature water to the glutinous rice to soak the rice, the water temperature is 23° C., and the rice soaking time is 12 hours.

[0053] (2) Steam rice: Put the soaked glutinous rice in a steamer to steam the rice; adjust the rice temperature of the steamed rice so that the temperature of the lower koji is kept at 29°C to 30°C; the amount of the lower koji is 1.2% of the weight of the feed ;

[0054] The added koji is composed of sweet wine koji and Saccharomyces cerevisiae I, and the mass ratio of sweet wine koji to Saccharomyces cerevisiae I is 1:1.

[0055] The preparation method of described Saccharomyces cerevisiae I is as follows:

[0056] S1. Preparation of culture medium: Weigh 13g of wort, add 3mL of lactic acid, 100mL of water, sterilize at 121°C, and obtain a culture medium after cooling, add 5mL of ethanol with a filter membrane to the above culture medium o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com