Drying system and technology of high chlorinated polyethylene resins

A high-chlorinated polyethylene, drying system technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of high-chlorinated polyethylene drying, etc., to ensure the drying effect and prolong the drying the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

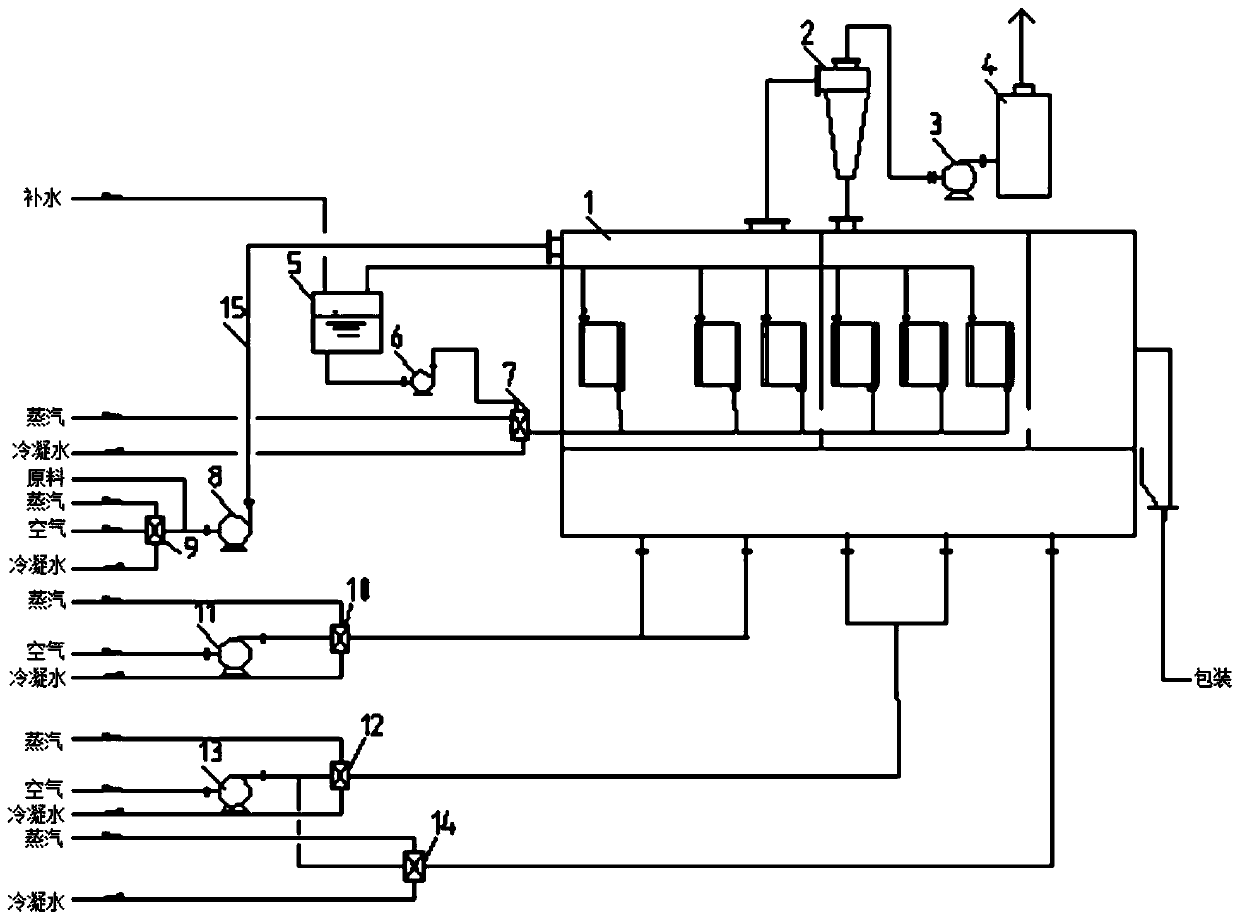

[0060] A drying system for high chlorinated polyethylene resin, such as figure 1 As shown, the internal heating fluidized bed 1 equipped with six sets of built-in tubular heat exchangers is used as the drying host, and the tubular heat exchanger has hot water inside, including the internal heating fluidized bed 1 and the cyclone dust collector 2. , induced draft fan 3, water washing tower 4, water storage tank 5, water pump 6, hot water heat exchanger 7, feeding fan 8, air heat exchanger 9, first hot air heat exchanger 10, first blower 11, second hot air Heat exchanger 12 , second air blower 13 , third hot air heat exchanger 14 .

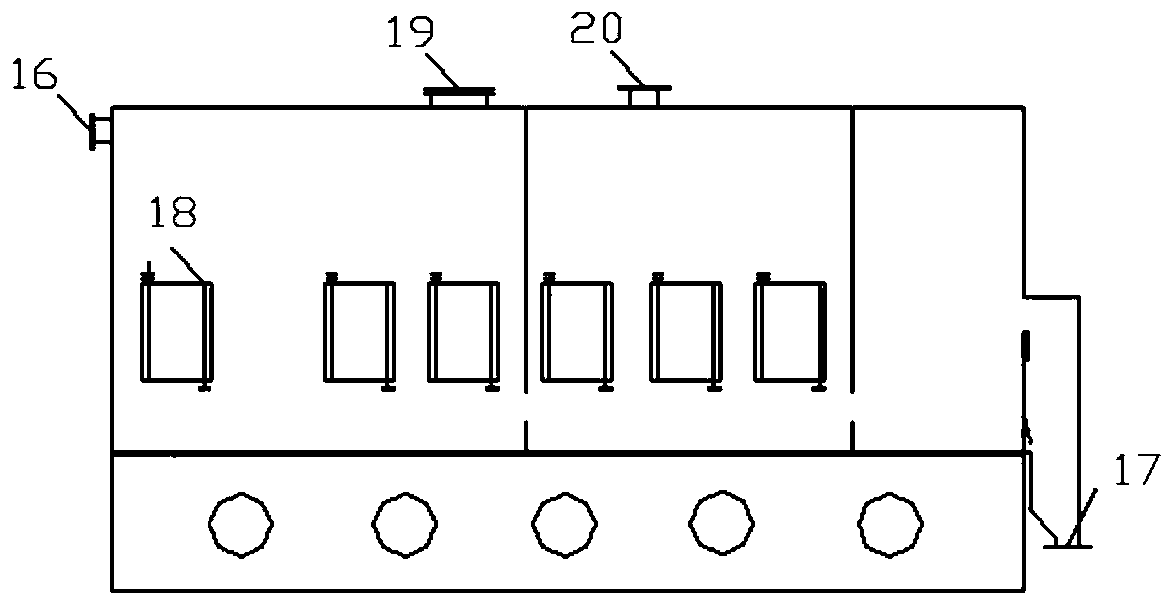

[0061] Internally heated fluidized bed 1, such as figure 2 As shown, it is a cylindrical structure arranged horizontally. One axial end of the cylindrical structure is provided with a material inlet 16 . The other axial end of the cylindrical structure is provided with a material outlet 17 . From the material inlet 16 to the material outlet 17,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com