Method for determining prohibition period of photoetching process node and simulation method

A technology of lithography process and simulation method, applied in the field of determining the prohibition period of lithography process nodes, can solve the problems of cumbersome, unable to effectively guide the formulation of layout design rules, unable to judge the poor quality of pattern lithography, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A specific embodiment of the present invention discloses a method for finding out the lithography forbidden period (forbiddenpitch, FP) by calculation simulation, such as Figure 14 shown, including the following steps:

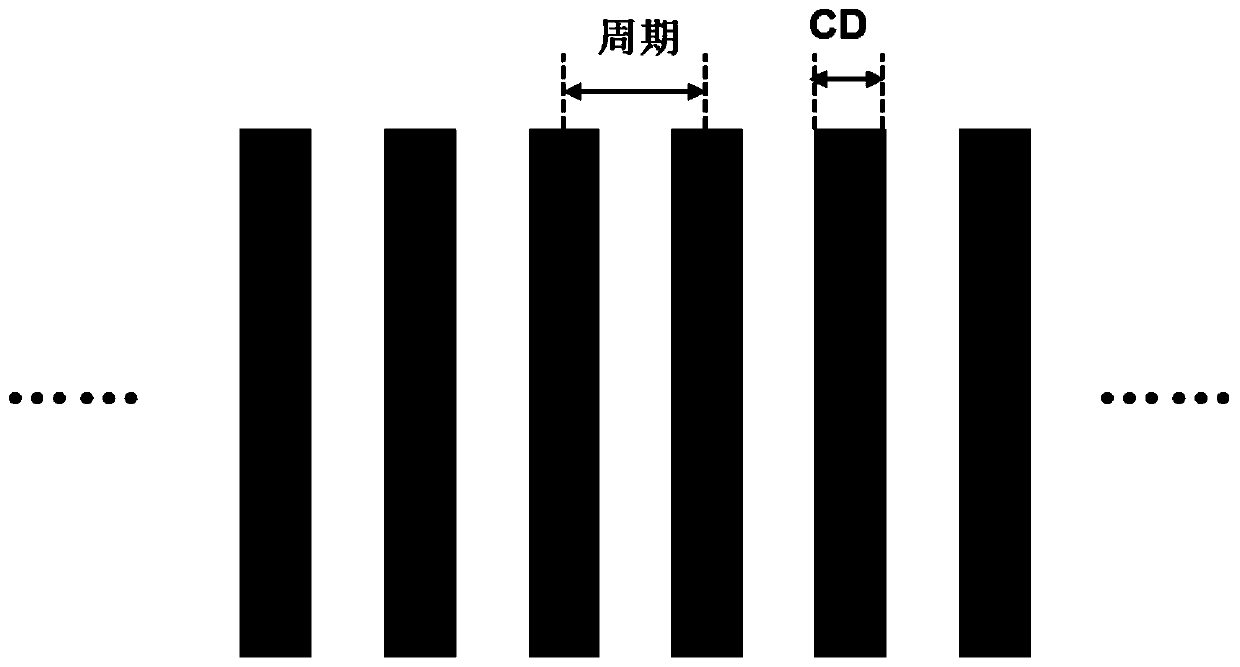

[0049] Step 1: Obtain a test pattern (test pattern), mainly a one-dimensional variable-period line (through pitch) pattern within a certain range, and the line width (critical dimension, CD) is the key line width (ie, key dimension) of the lithography node , for example, the actual key line width of the 14nm node is 38nm, and the period (pitch) should include as much as possible;

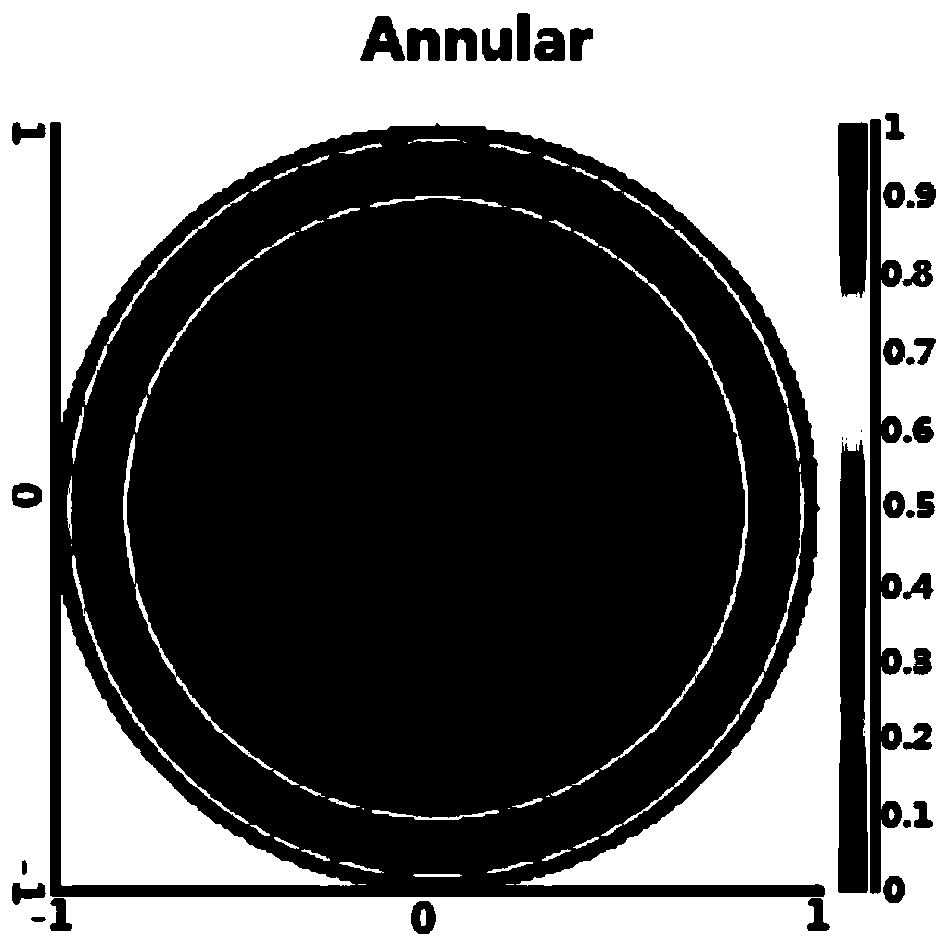

[0050] Step 2: Set initial simulation light source parameters (for example, a circular light source or a ring light source is used as the initial light source, and a ring light source is used as the initial light source in this embodiment) and related simulation parameters, such as the model of the lithography machine, NA (numerical aperture) value, Reticle parameters and p...

Embodiment 2

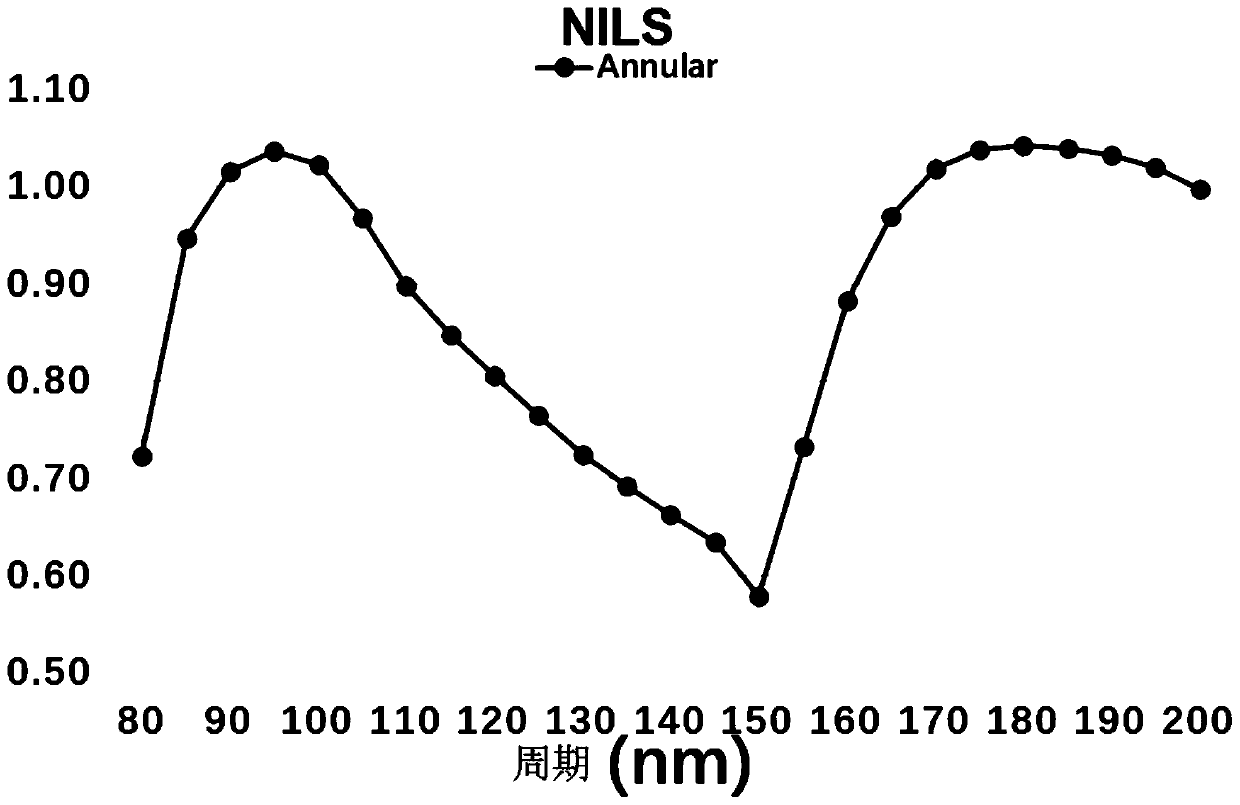

[0060] The resolution limit size of the 193nm immersion lithography technology is 76nm. In this embodiment, we use a test pattern with a minimum period of 80nm. First obtain the test pattern (test pattern), mainly one-dimensional variable period (the present embodiment is 80nm-200nm) line (through pitch) pattern within a certain range, such as Figure 8 shown. The line width (CD) is the minimum dimension of the lithography node. In this embodiment, a one-dimensional pattern with CD=40nm is selected, and the period (pitch) includes as much as possible. Set the parameters of the initial simulated light source (for example, a circular light source or a ring light source is used as the initial light source, and the ring light source selected in this embodiment is used as the initial light source, such as Figure 9 shown. Relevant simulation parameters include lithography machine model NXT1950i, NA (numerical aperture) value of 1.35, mask plate parameters, photoresist parameters,...

Embodiment 3

[0070] A specific embodiment of the present invention discloses a method for improving photolithography performance by optimizing a one-dimensional line pattern structure in which prohibited periods and dense periods are alternately arranged, including the following steps:

[0071] Step 1: Obtain an optimized free light source considering the global situation. Obtain various types of test patterns as comprehensive as possible from the actual layout as the initial layout input. Initial light source parameters (generally, a ring light source is used as the initial light source) and related simulation parameters include lithography machine model, NA (numerical aperture) value, mask plate parameters (thickness, refractive index, etc.), etc.;

[0072] Step 2: Under the above parameter settings, use professional simulation software to perform collaborative optimization of light source mask (SMO) to obtain the optimized free light source (freeform source1), and analyze the data to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com