Patents

Literature

46results about How to "Multiple preferred combinations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

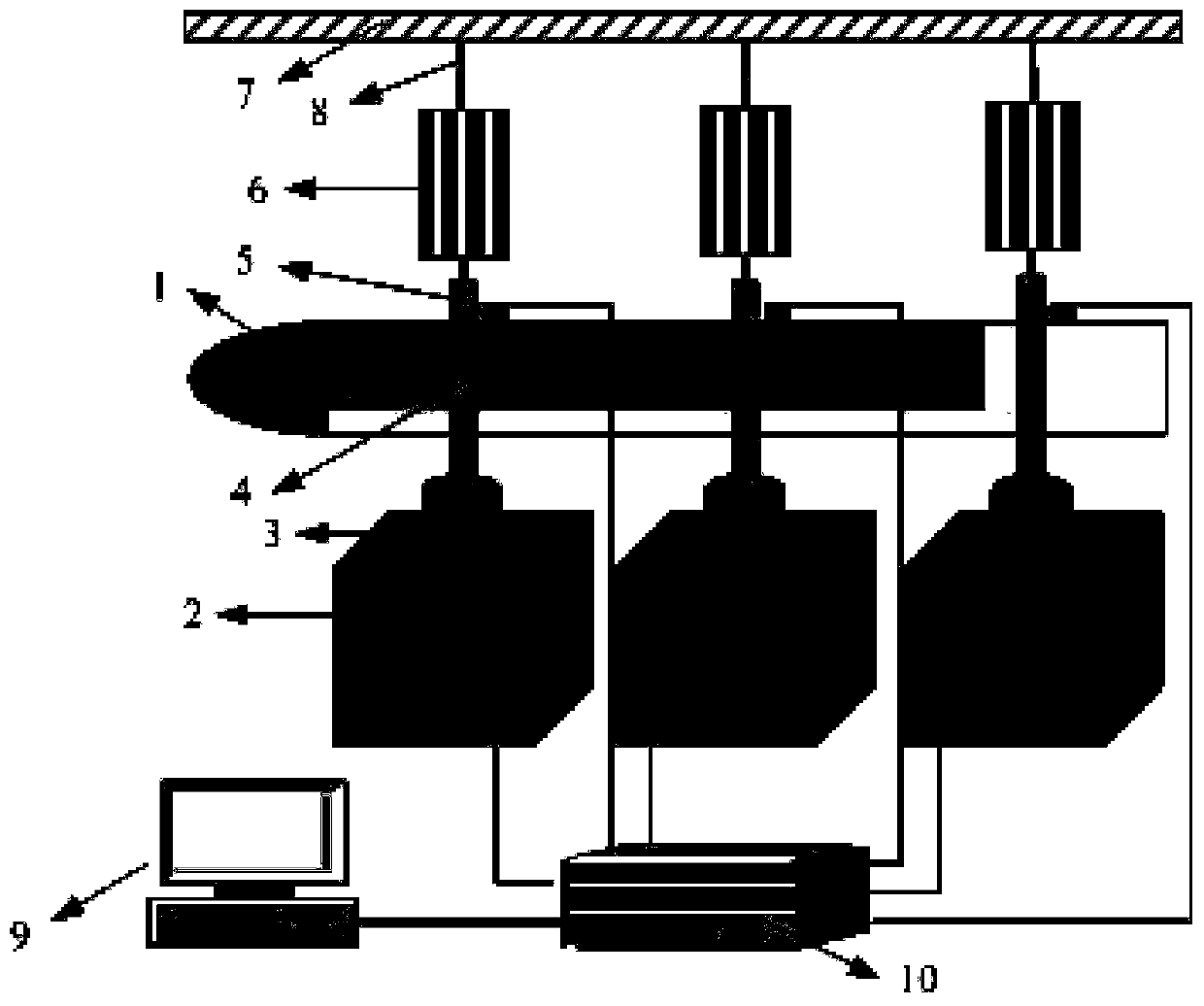

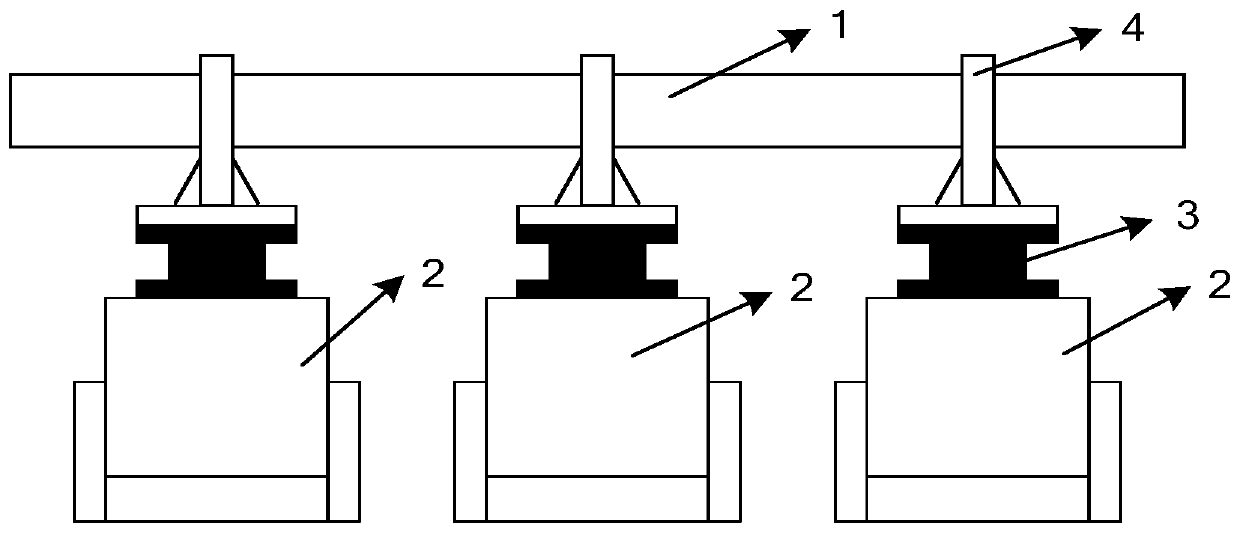

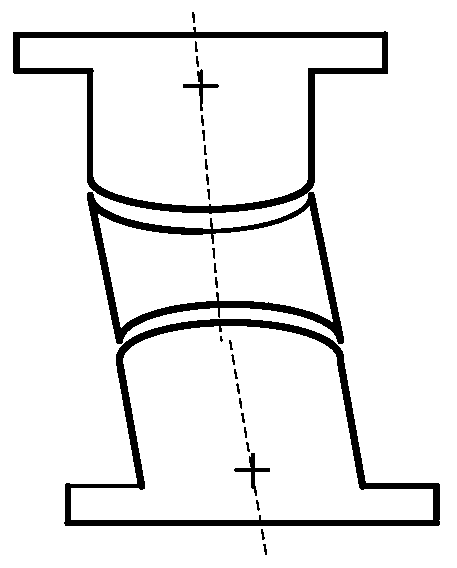

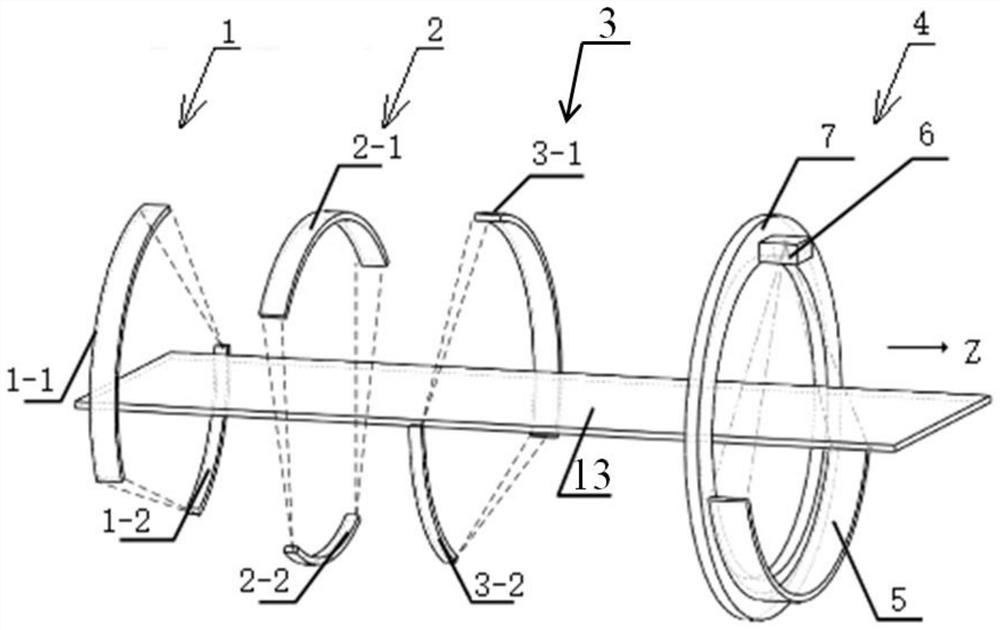

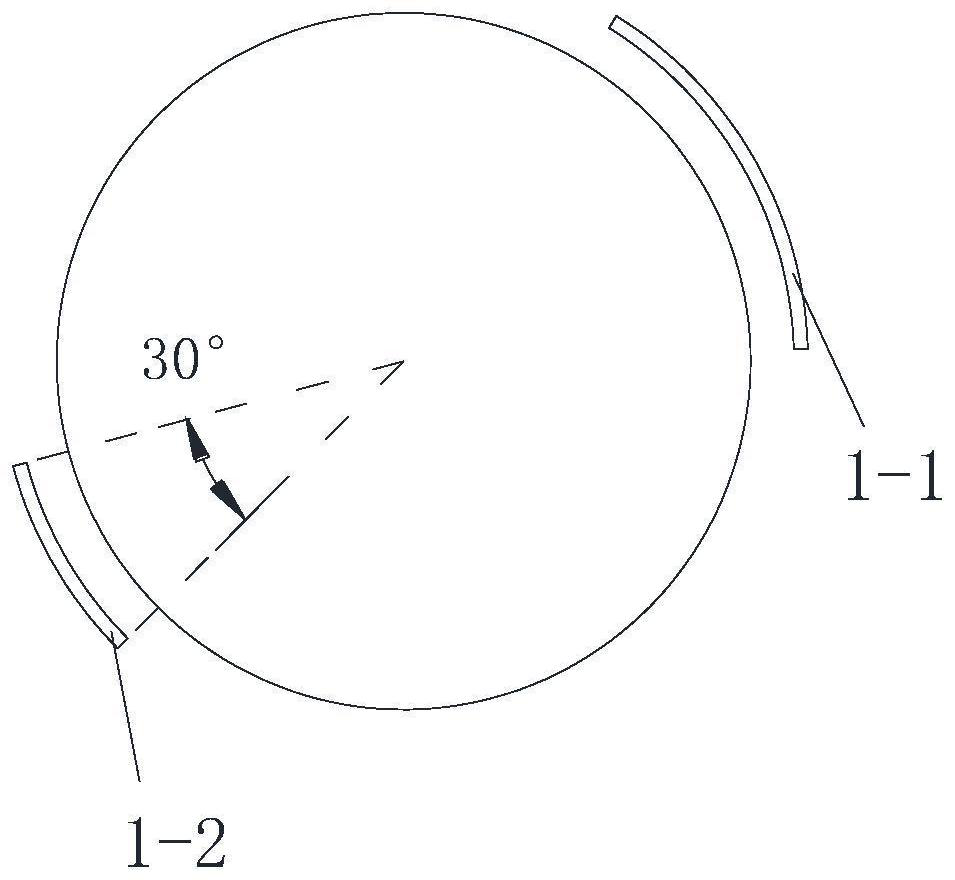

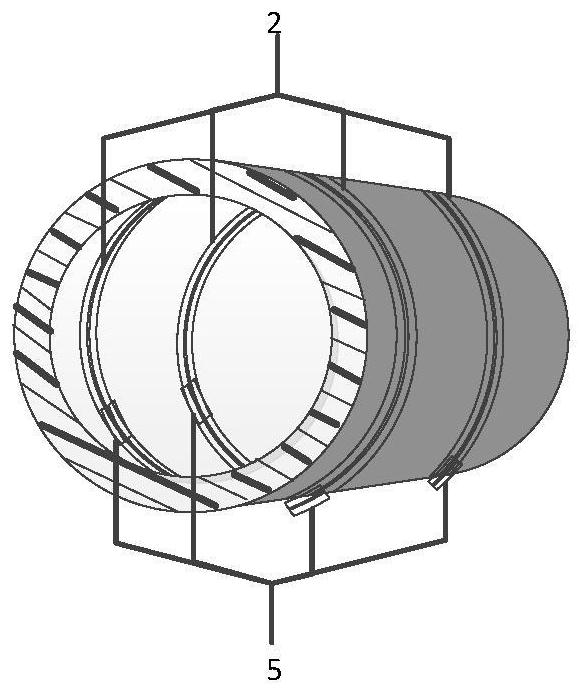

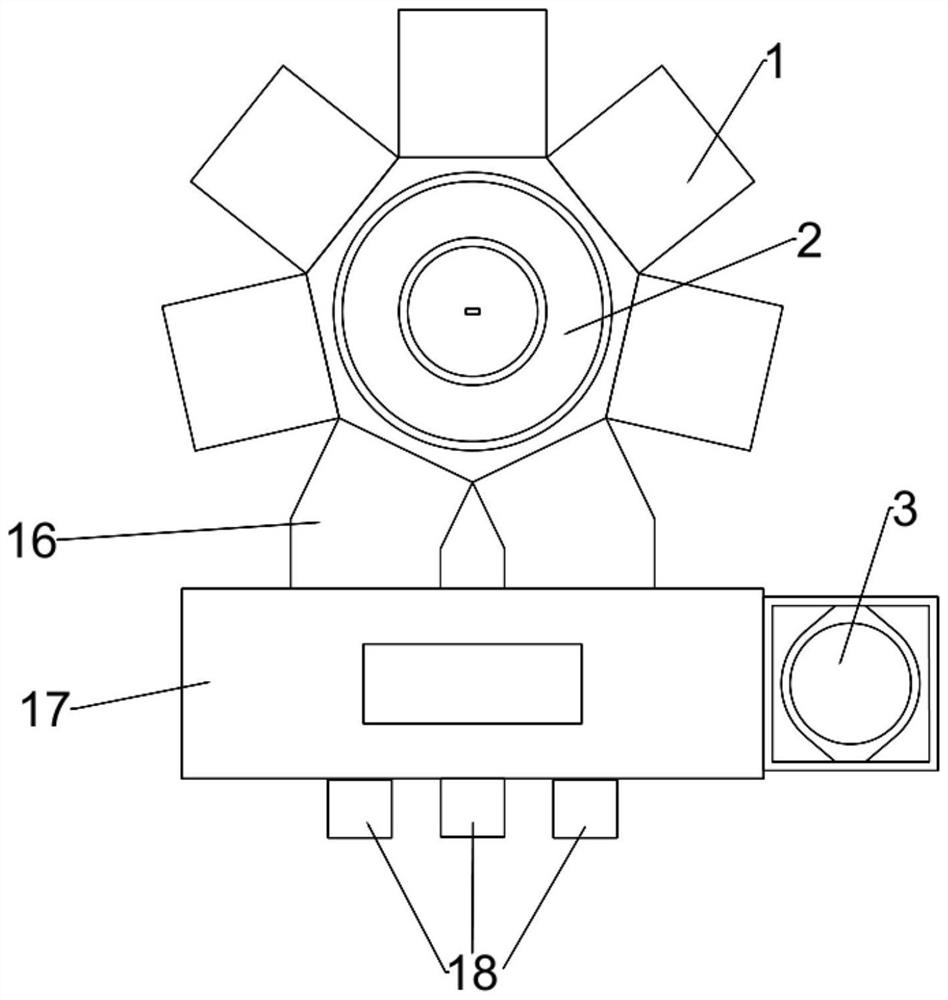

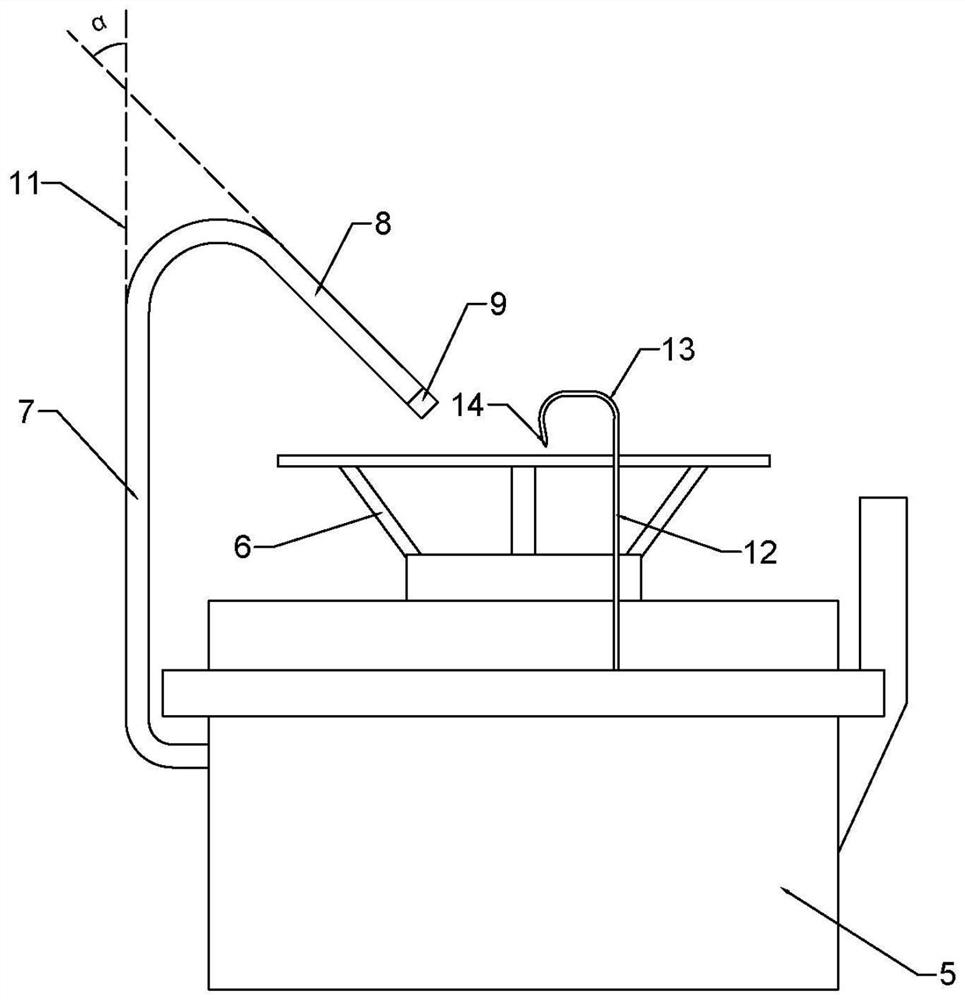

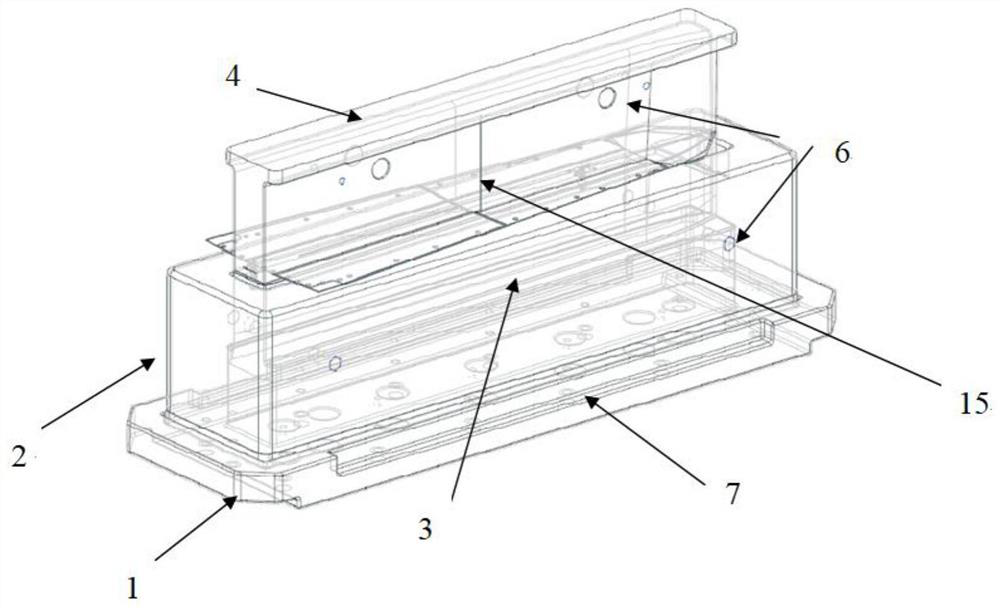

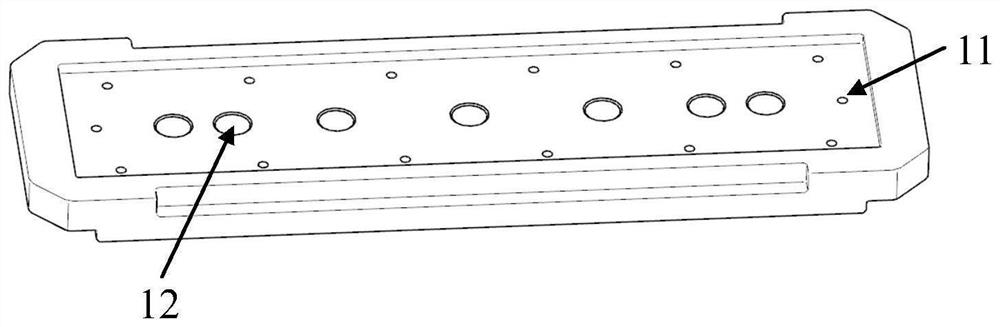

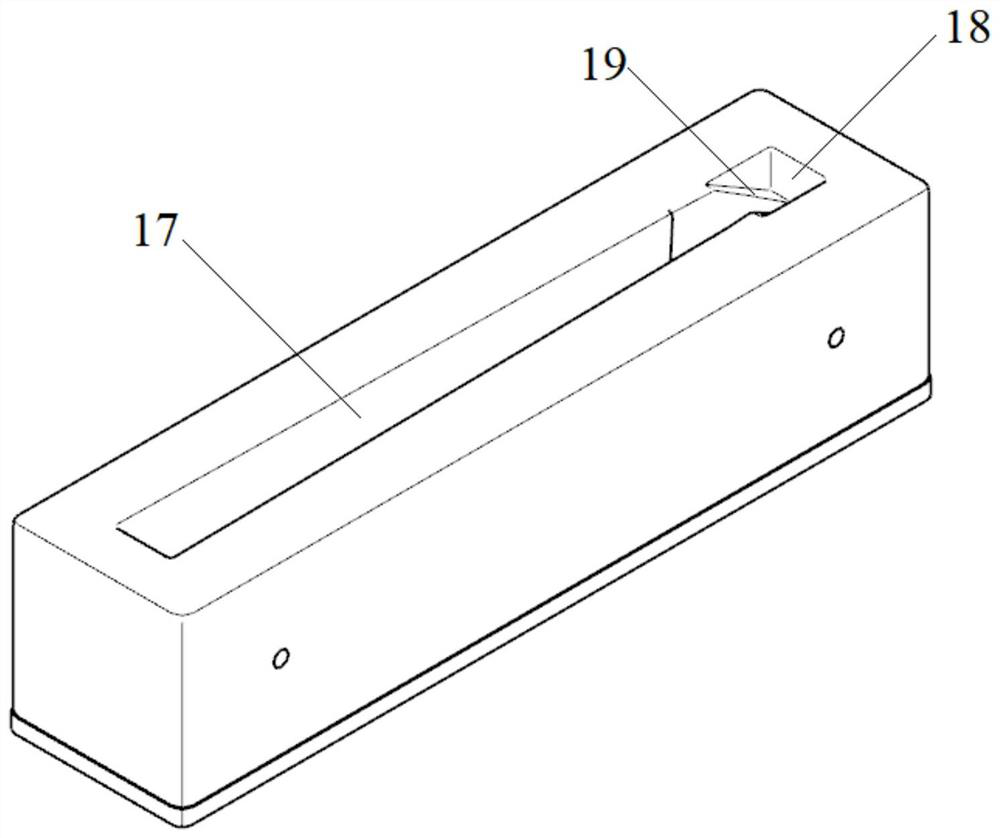

Vibration system comprising plurality of vibration tables and vibration test method

ActiveCN110895186AReal and reasonable use environmentEvenly distributedSustainable transportationVibration testingVibration controlControl system

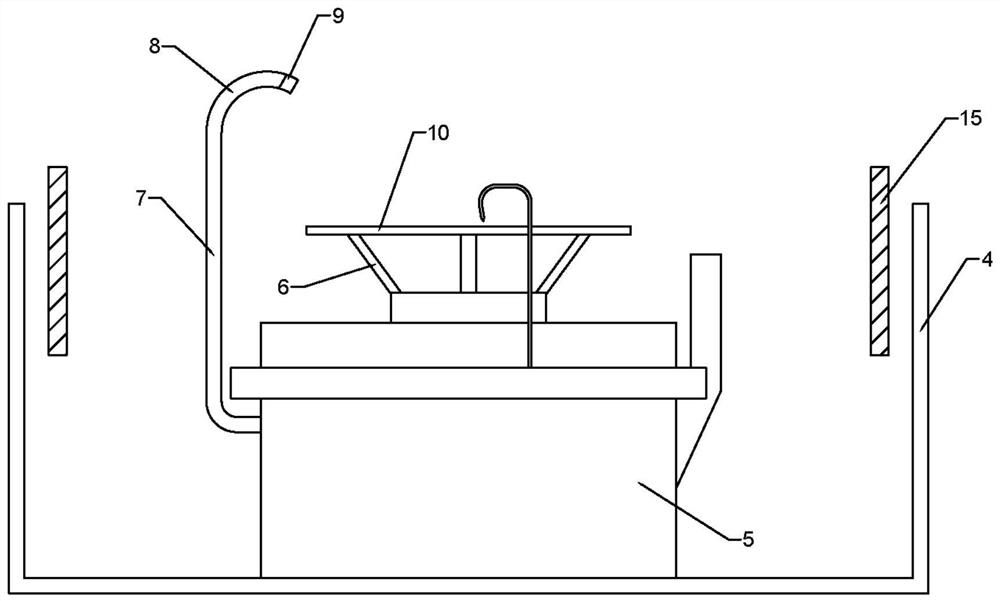

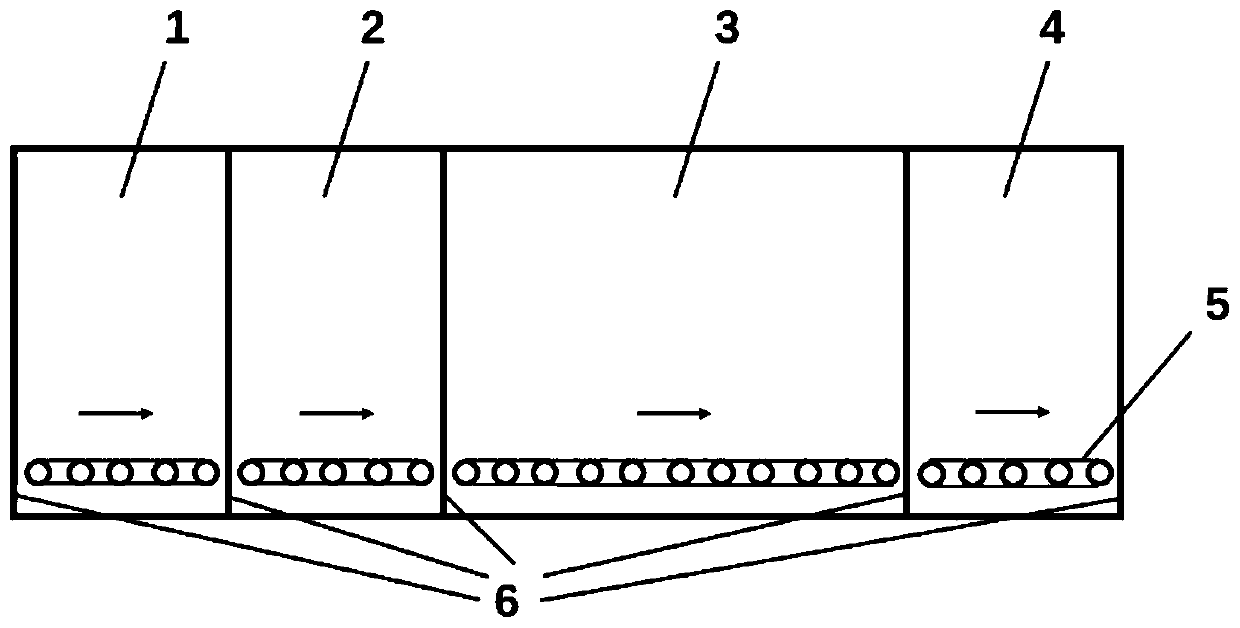

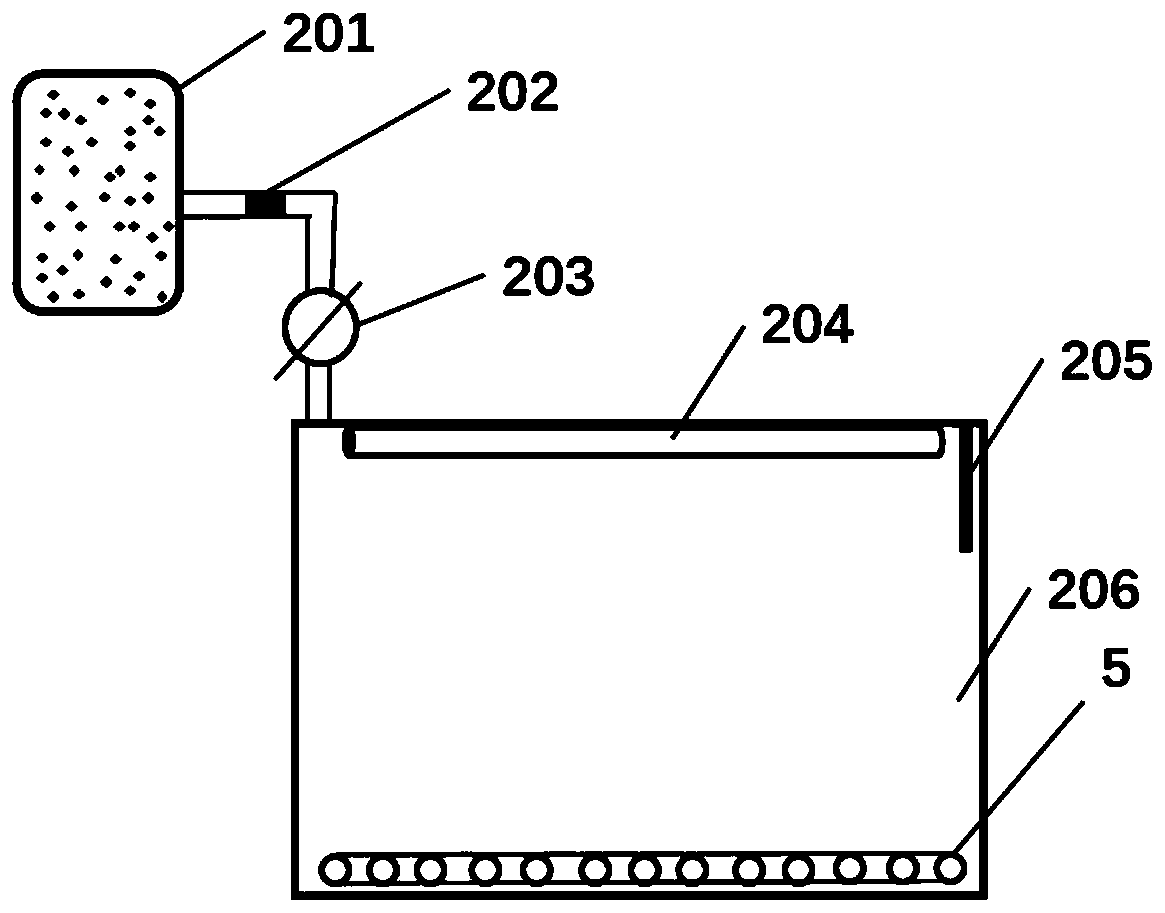

The invention relates to a vibration system comprising a plurality of vibration tables and a vibration test method, belongs to the technical field of vibration tests, and solves the problems that in the prior art, a vibration system cannot realize multiple uniaxial vibration environments in a laboratory, so that a tested part is subjected to an over-test or an under-test, and the reliability evaluation of a tested product is influenced. The vibration system comprises a test part, a vibration table system, a mechanical decoupling system, a test fixture, a sensor and a vibration control system.The vibration test method comprises the following steps: arranging excitation points, and installing a test part, a test fixture and a mechanical decoupling device; pasting a sensor on the test part;setting random vibration test conditions and a control mode; collection of test data. According to the invention, the vibration load distribution of the slender body structure test part is more uniform, reasonable and real, the stress concentration caused by single excitation is reduced, and the local under-test or over-test degree is reduced.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

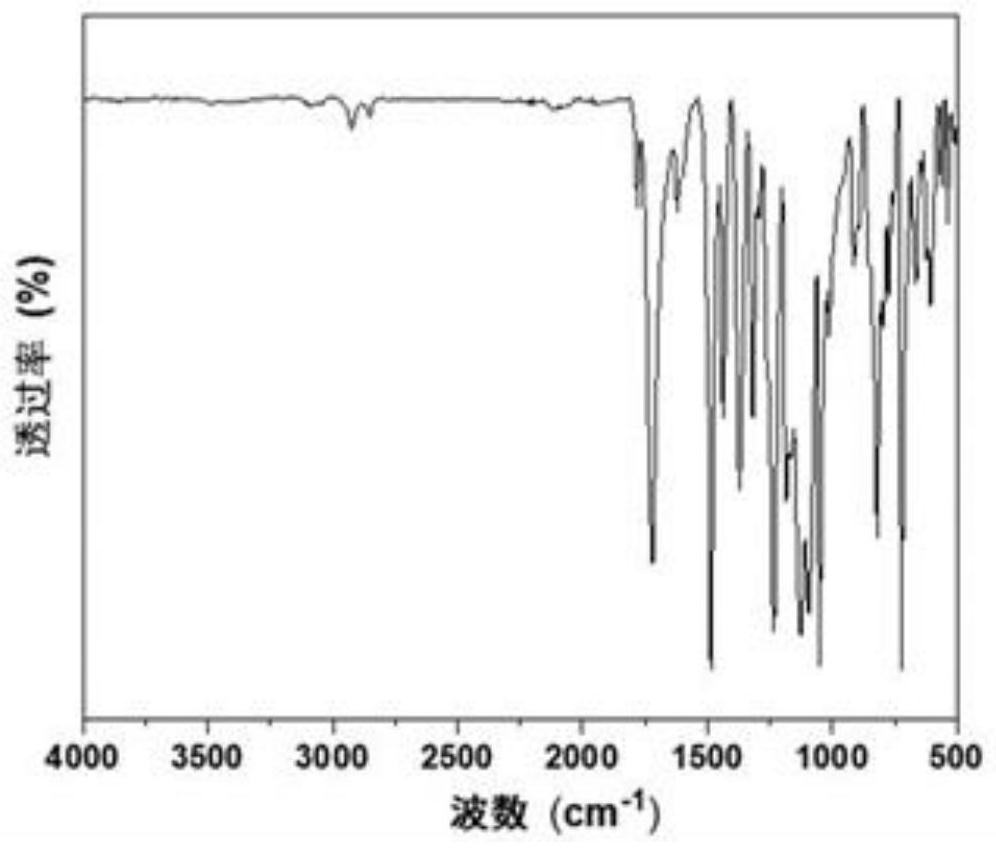

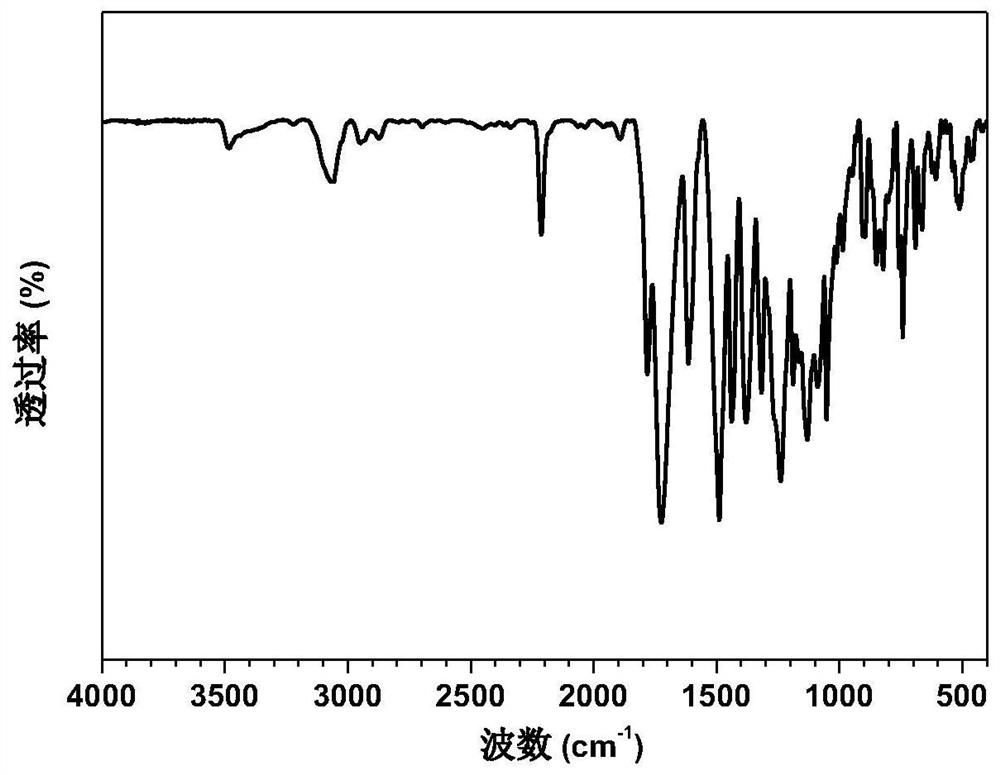

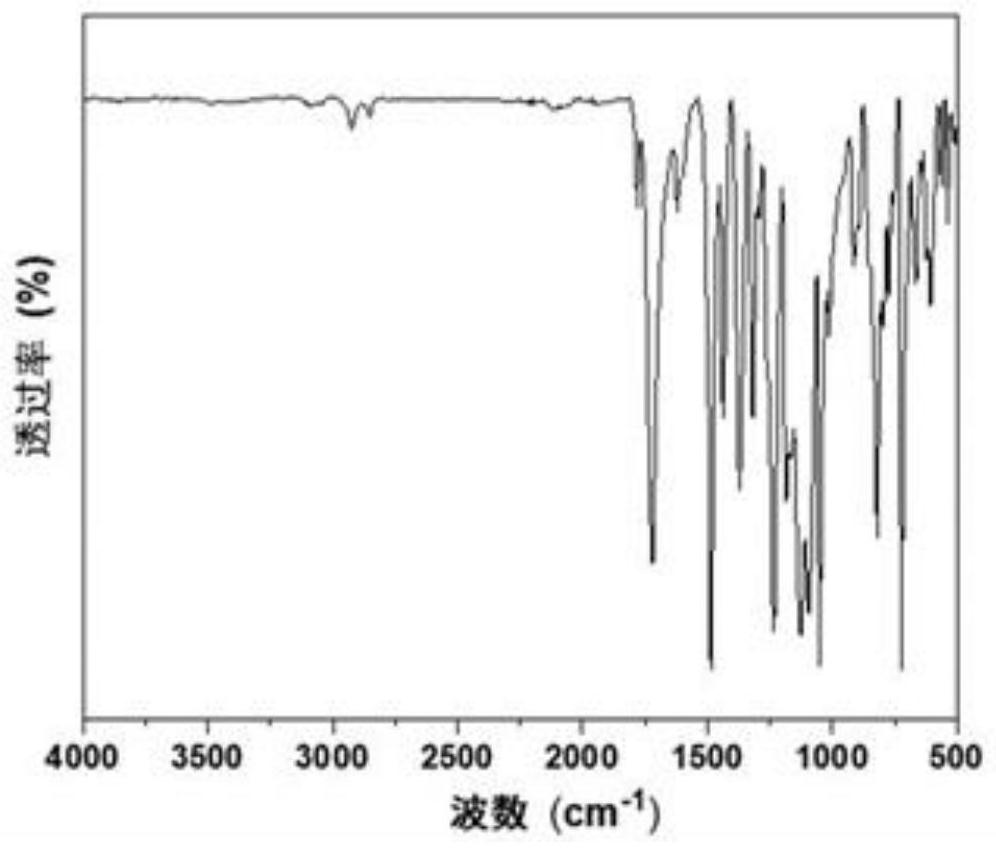

Polyimide adhesive film with excellent comprehensive performance as well as preparation method and application thereof

ActiveCN113248708AImprove hot melt effectSmall dielectric lossFilm/foil adhesives without carriersPolymer scienceDielectric loss

The invention relates to a polyimide adhesive film with excellent comprehensive performance as well as a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that an existing polyimide adhesive film can hardly have excellent heat resistance, good adhesive property, low dielectric constant at high frequency and low dielectric loss. The polyimide adhesive film is mainly prepared from aromatic dianhydride, aromatic diamine containing a diphenyl ether structure and diamine containing a siloxane structure. The polyimide adhesive film has excellent heat resistance, high-frequency low dielectric property and good adhesive property. The glass-transition temperature is higher than 330 DEG C, the dielectric constant (Dk) at 10 GHz is smaller than 3, the dielectric loss (Df) value is 0.003-0.006, and the peel strength after the polyimide adhesive film is in hot-pressing adhesive connection with a copper foil is larger than 10 N / cm. The application requirements of flexible printed circuit board manufacturing and interlayer bonding and insulation in multi-layer circuit board lamination wiring processing can be met. The polyimide adhesive film provided by the invention can be widely applied to the fields of high-frequency flexible printed circuit boards, high-frequency film antennas and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

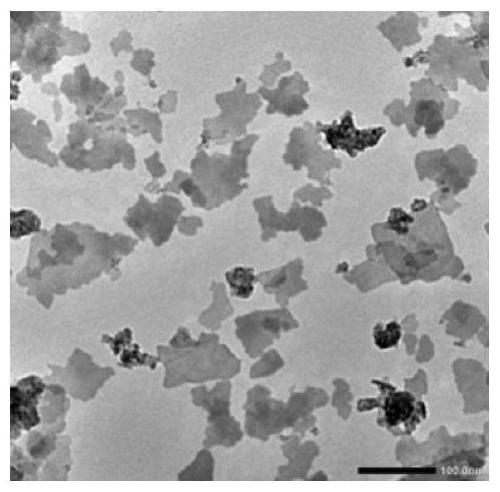

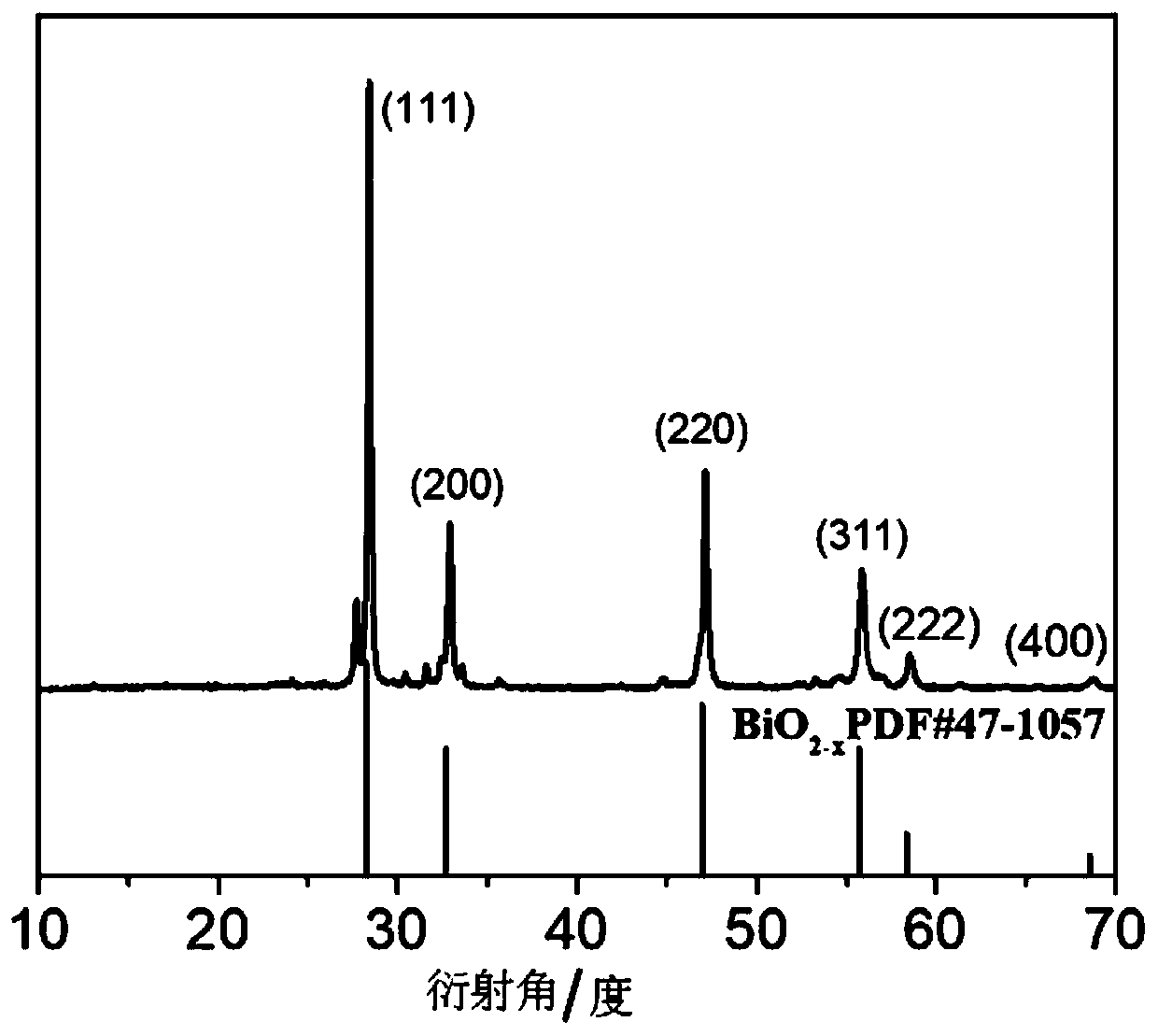

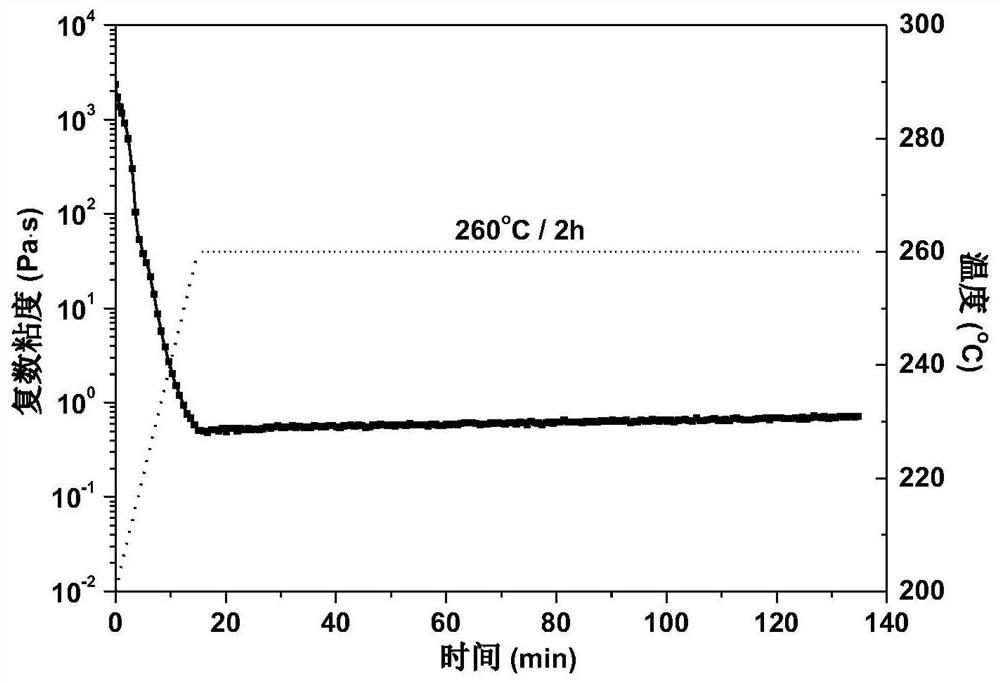

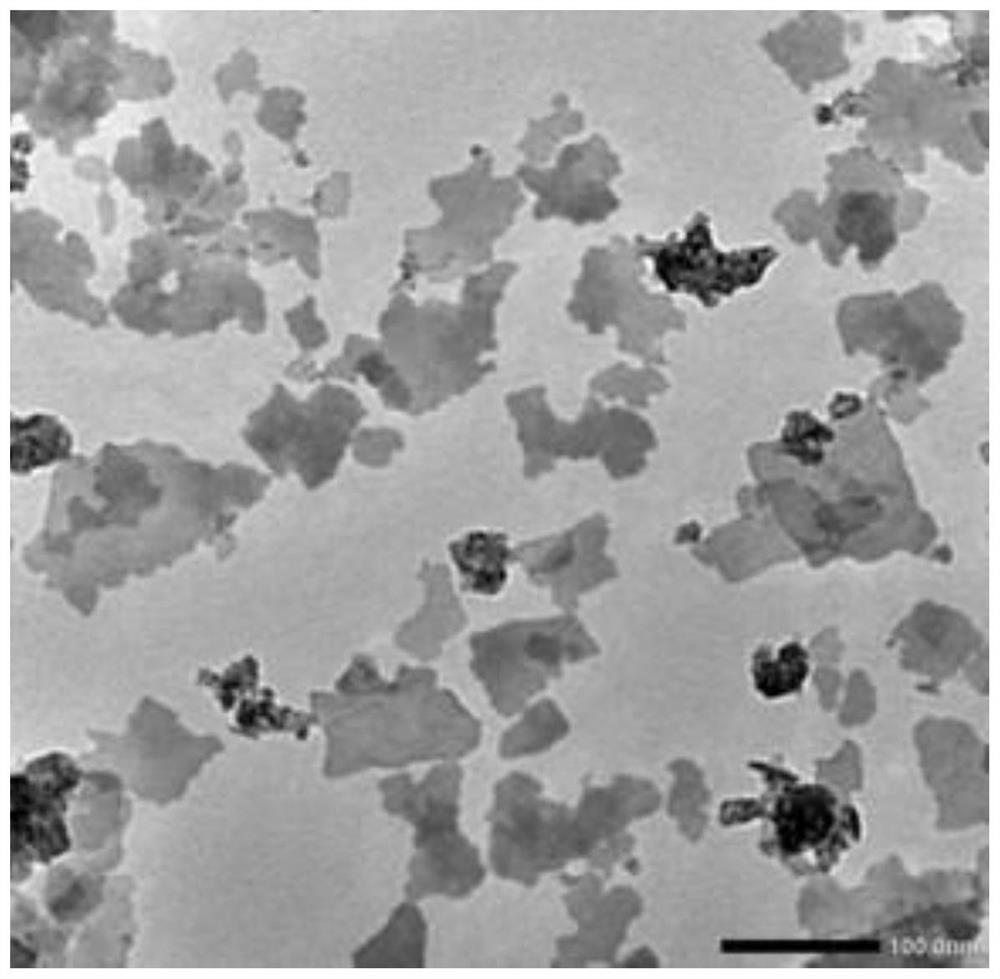

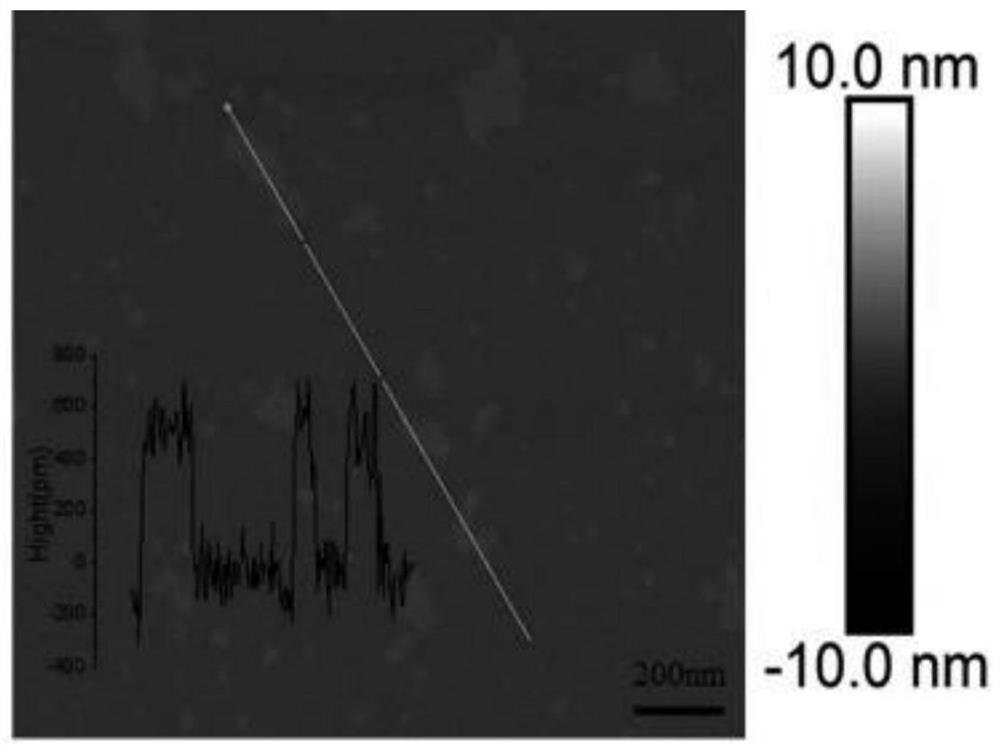

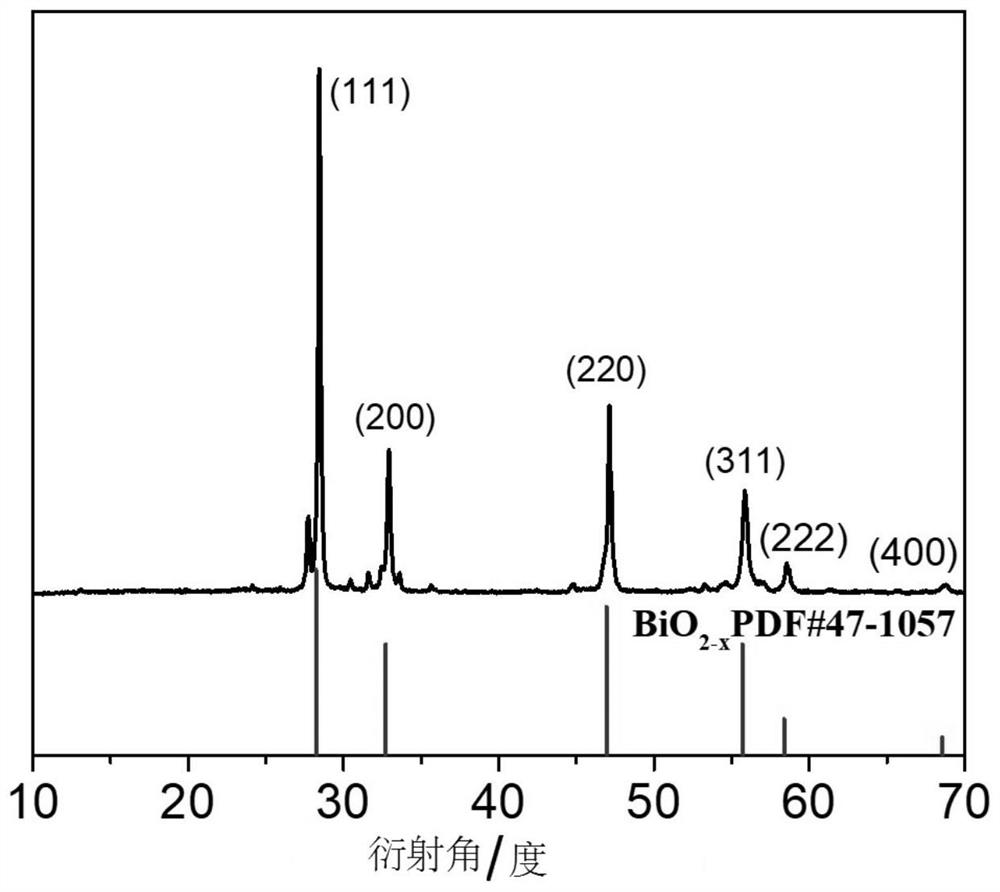

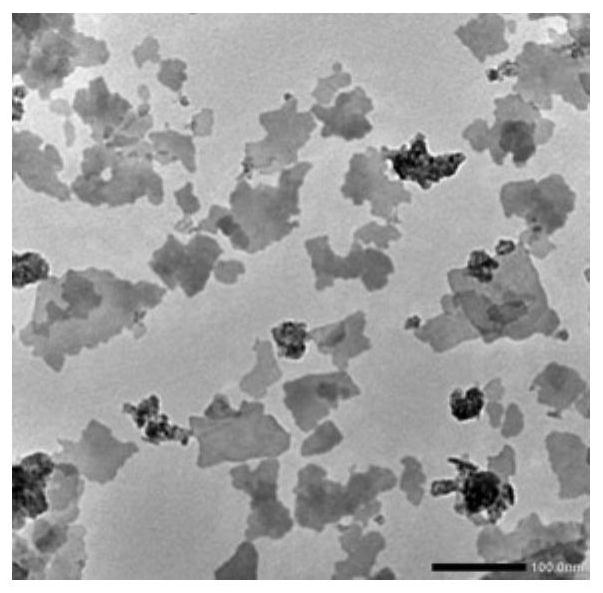

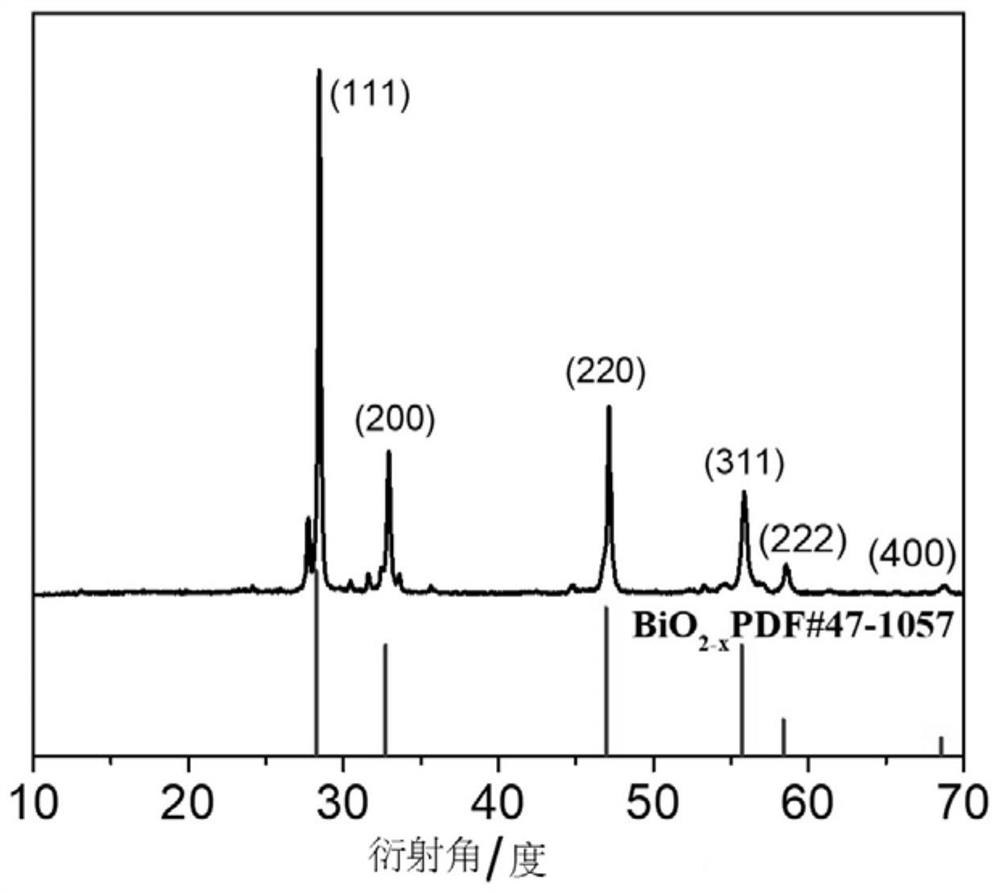

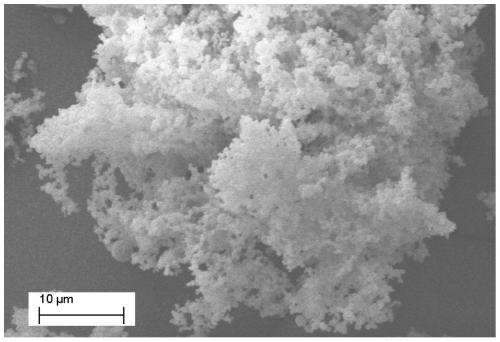

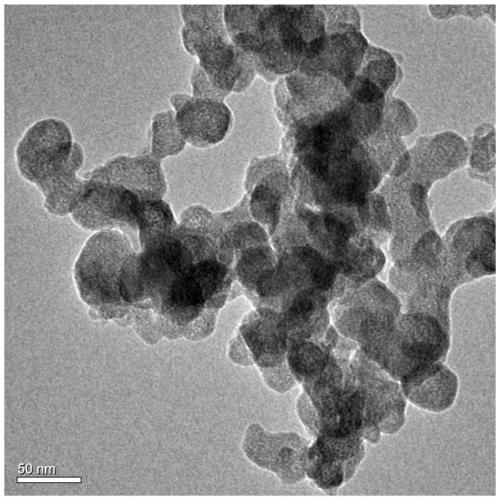

Sensitizer for radiotherapy and preparation method and application of sensitizer

ActiveCN111035761AHigh-efficiency catalytic productionImprove hypoxiaInorganic active ingredientsNanomedicineOxygen vacancyDelivered radiation dose

The invention relates to a sensitizer for radiotherapy and a preparation method and application of the sensitizer, belongs to the field of nano material chemistry and biochemistry, and solves the problems that the existing radiotherapy sensitizer cannot improve the hypoxic state in a tumor microenvironment, is insensitive to radiotherapy, large in dosage of a radiation agent and large in damage tonormal tissues. The molecular formula of the sensitizer for radiotherapy is BiO2-x, the molecular structure has oxygen vacancy, and the preparation raw material of the sensitizer comprises hydroxideof alkali metal and bismuthate. The preparation method of the sensitizer comprises the following steps: dissolving the hydroxide of alkali metal and the bismuthate, and stirring to obtain a solution;transferring the solution into a reaction container, heating, and reacting for a period of time; the BiO2-x provided by the invention can be used as the sensitizer to be applied to radiotherapy sensitization of tumors, and has a very good inhibition effect on tumors under a relatively low radiation dose.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

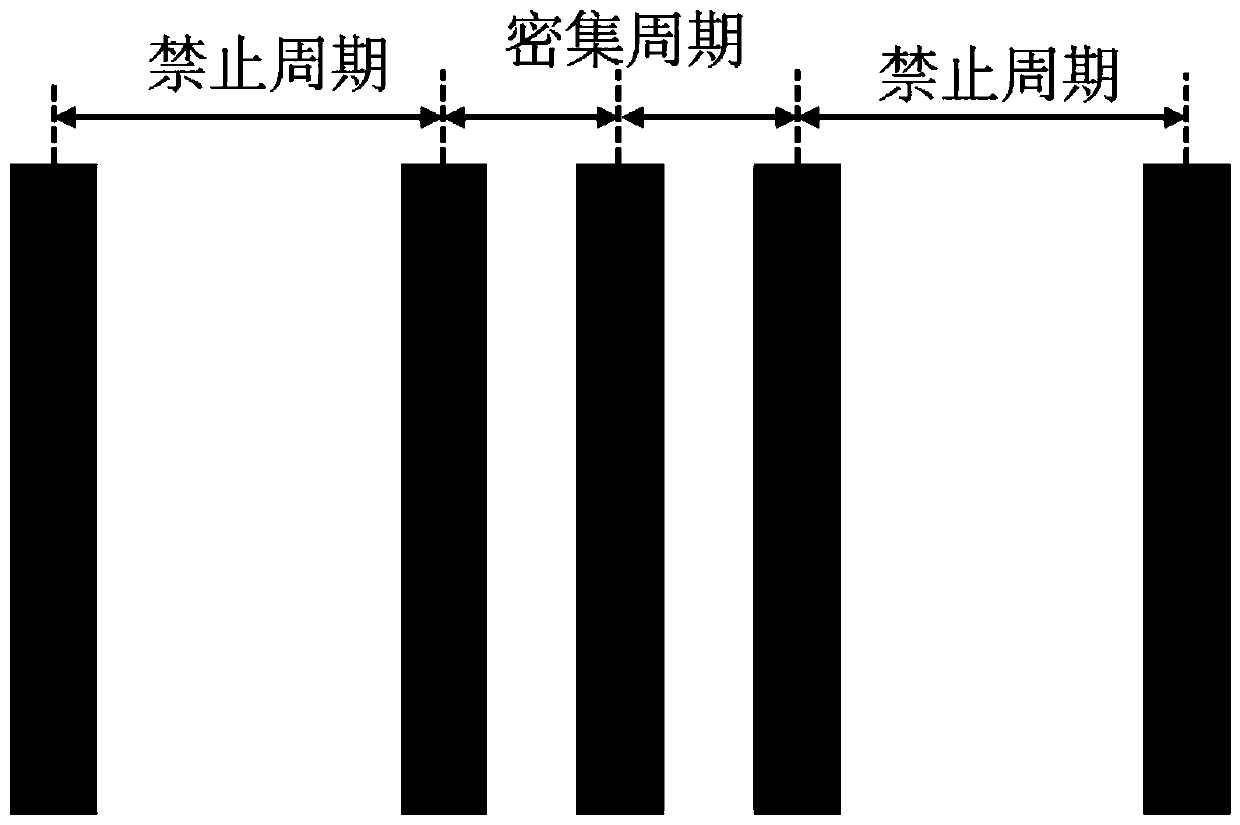

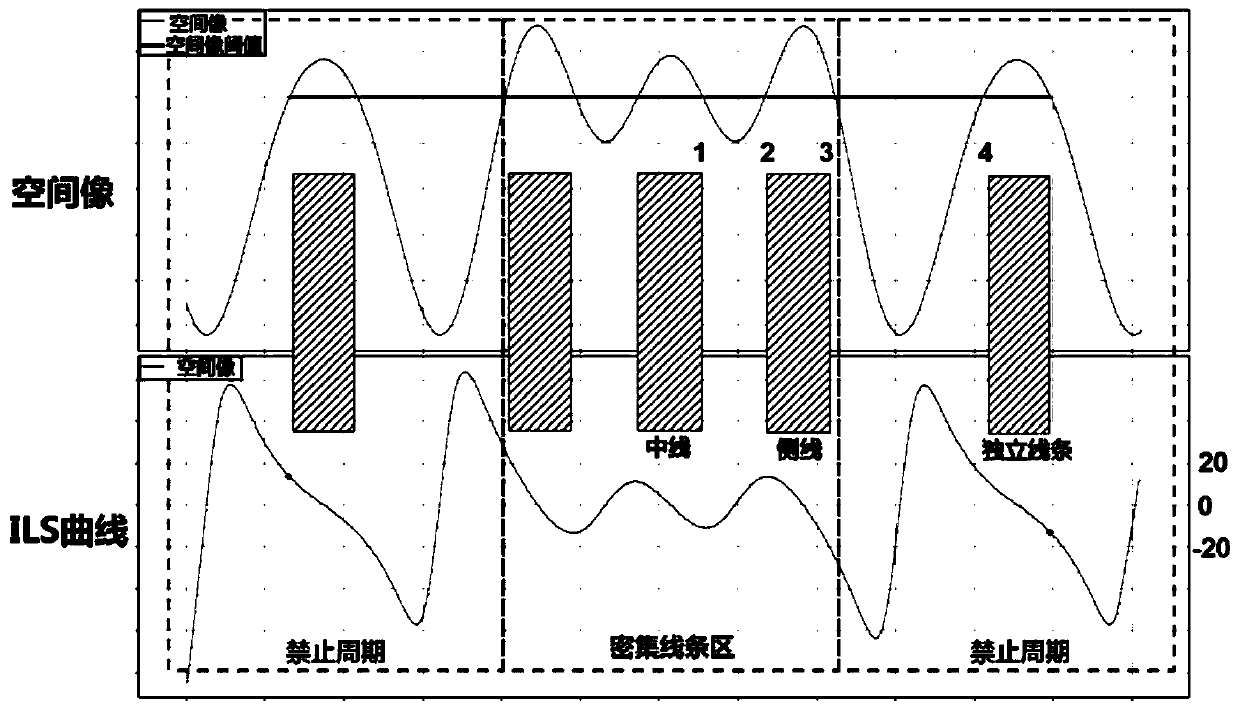

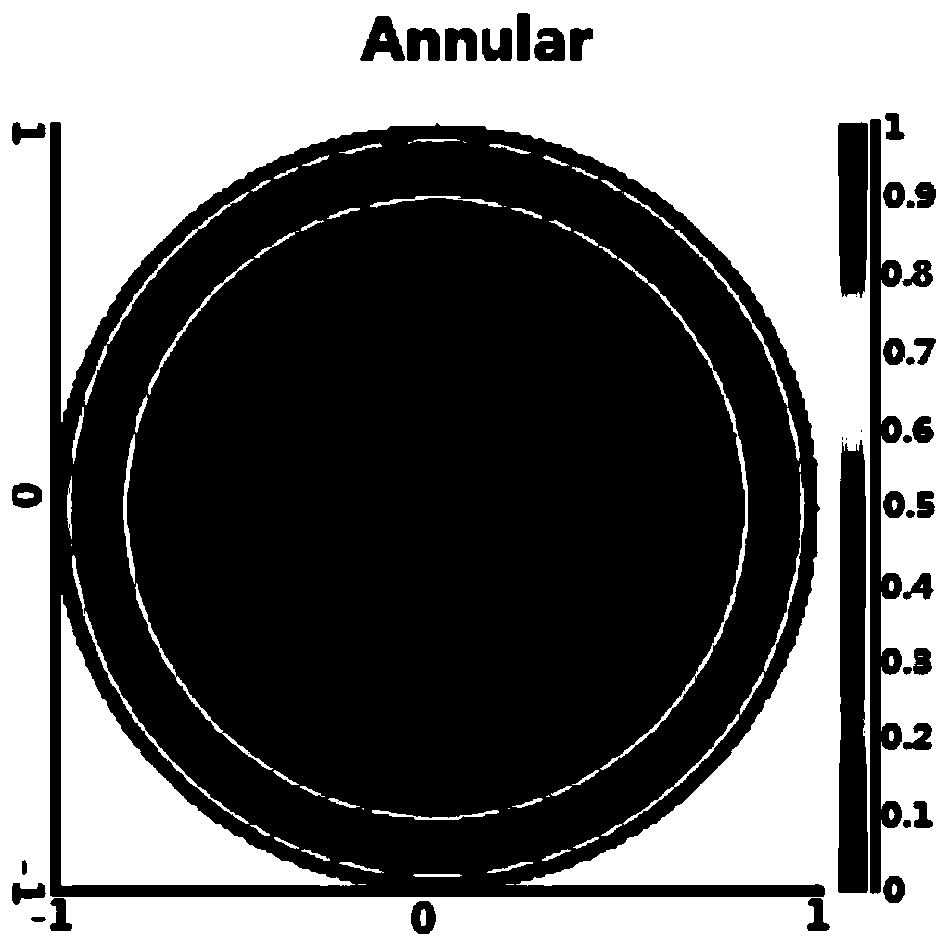

Method for improving layout photoetching performance, corrected layout and simulation method

PendingCN110989289ADOF improvementImprove photolithography qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusLayoutEngineering

The invention relates to a method for improving A layout photoetching performance, a corrected layout and a simulation method, and belongs to the technical field of semiconductor photoetching, and solves the problems that the process window of the whole layout is reduced and the photoetching quality is obviously reduced because the mutual restriction of a prohibition periodic effect and a dense periodic line cannot be effectively inhibited and the traditional OPC is difficult to balance and solve in the prior art. The method for improving the photoetching performance comprises the following steps of: obtaining a most representative graph in a graph category with remarkable influence on the photoetching performance through simulation; increasing the width of a forbidden period side edge single line; fixing the position of the middle line of a dense periodic line, and keeping the size of the middle line unchanged; and outwards widening the outer side edge edge3 of the side edge line of the dense periodic line by a certain distance delta edge3 to obtain an adjusted and corrected graph. According to the invention, the photoetching performance of the layout is improved with low cost andlow risk.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

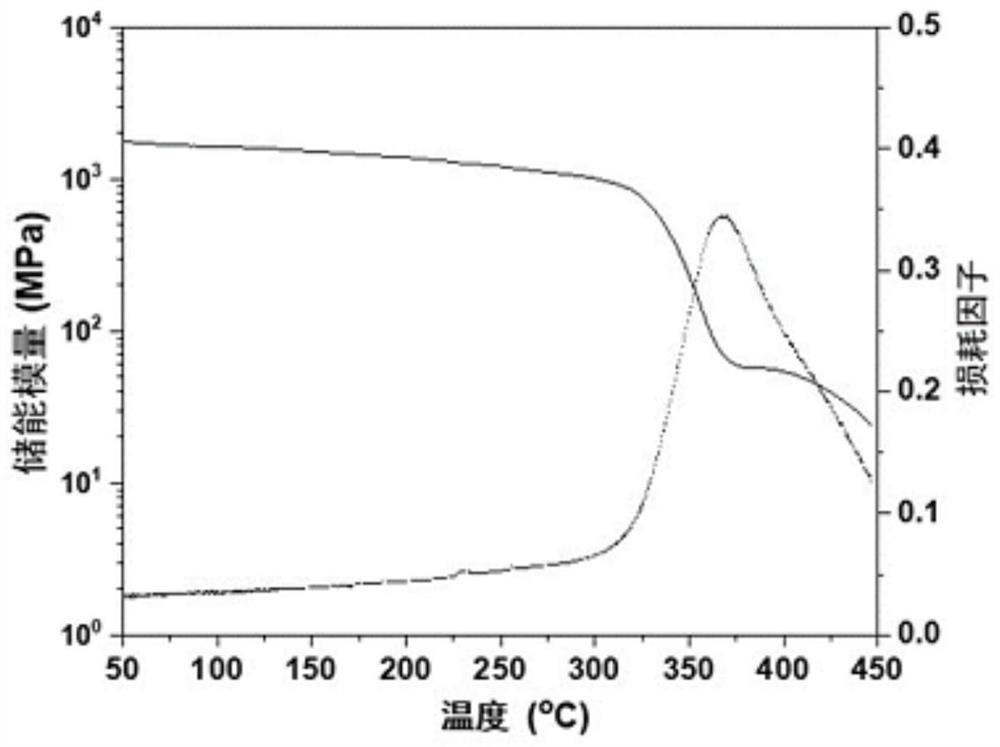

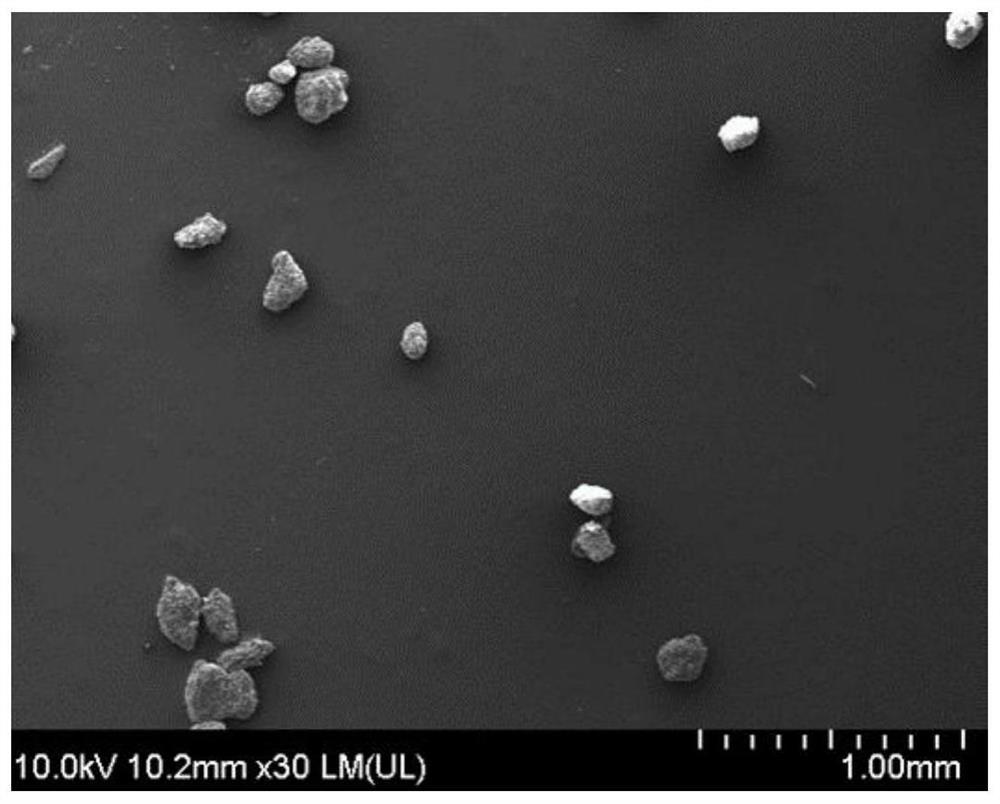

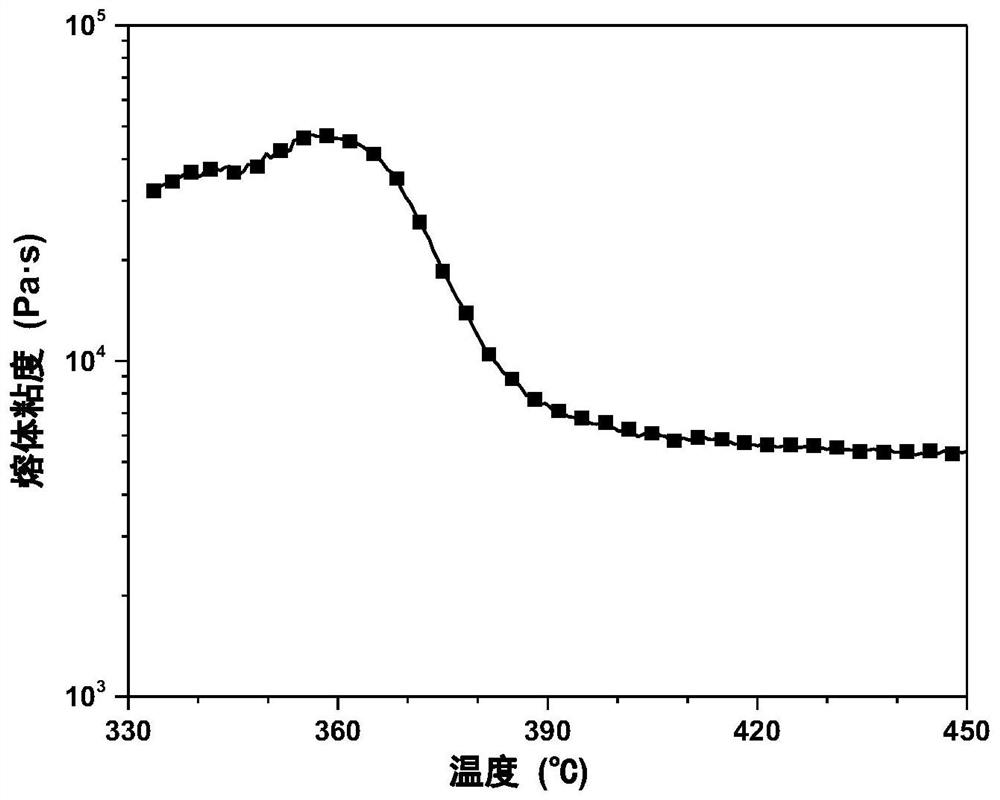

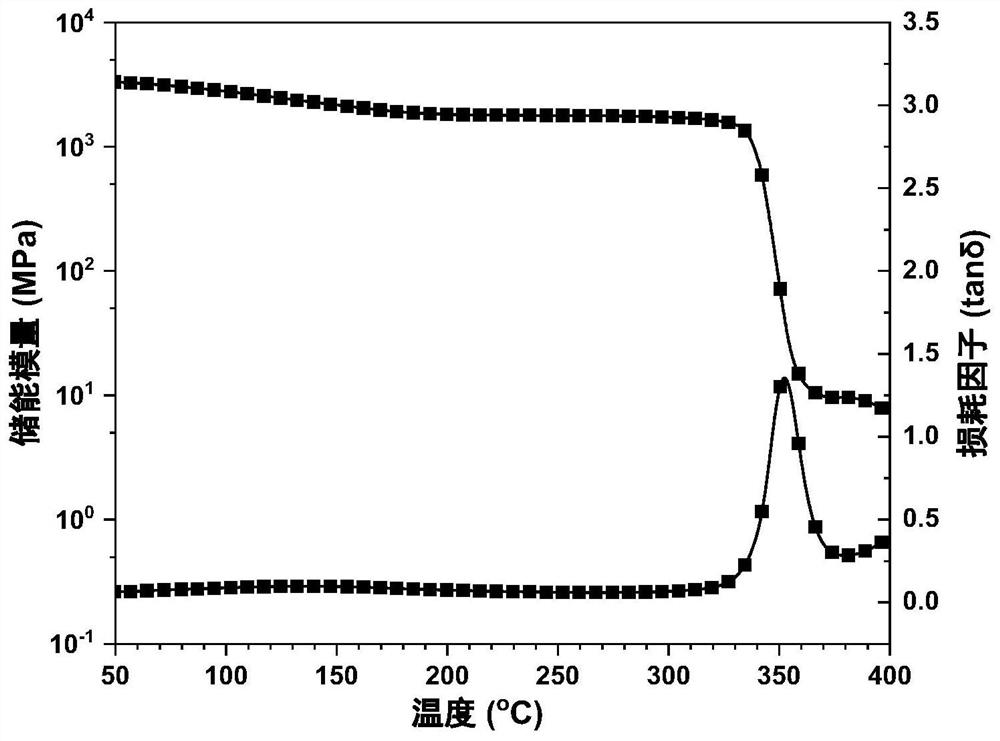

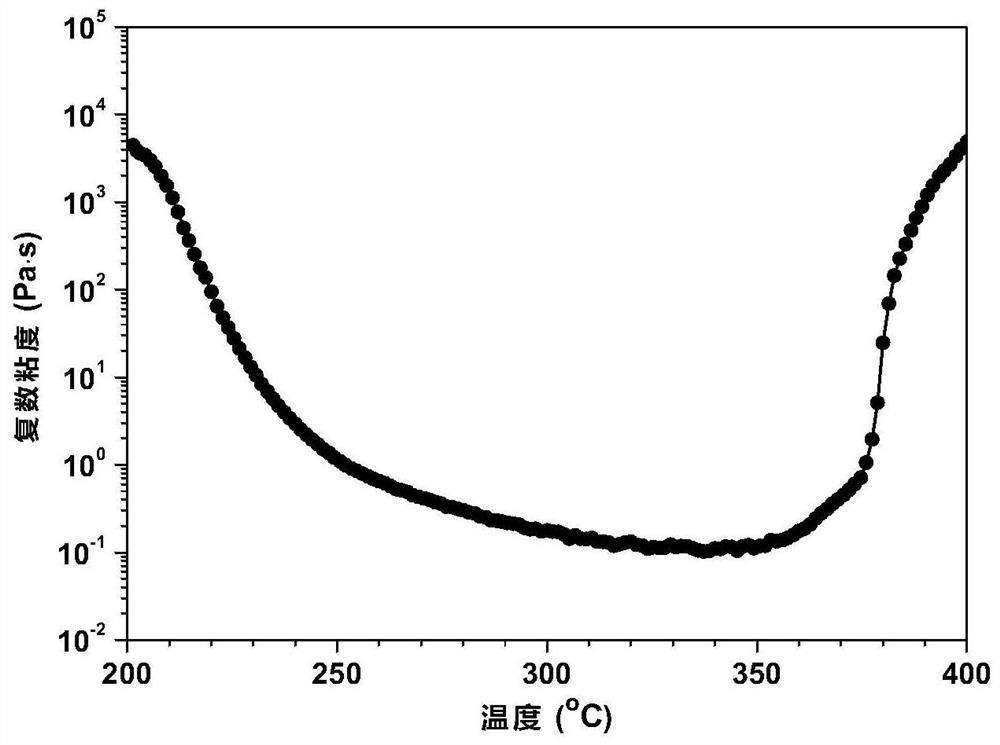

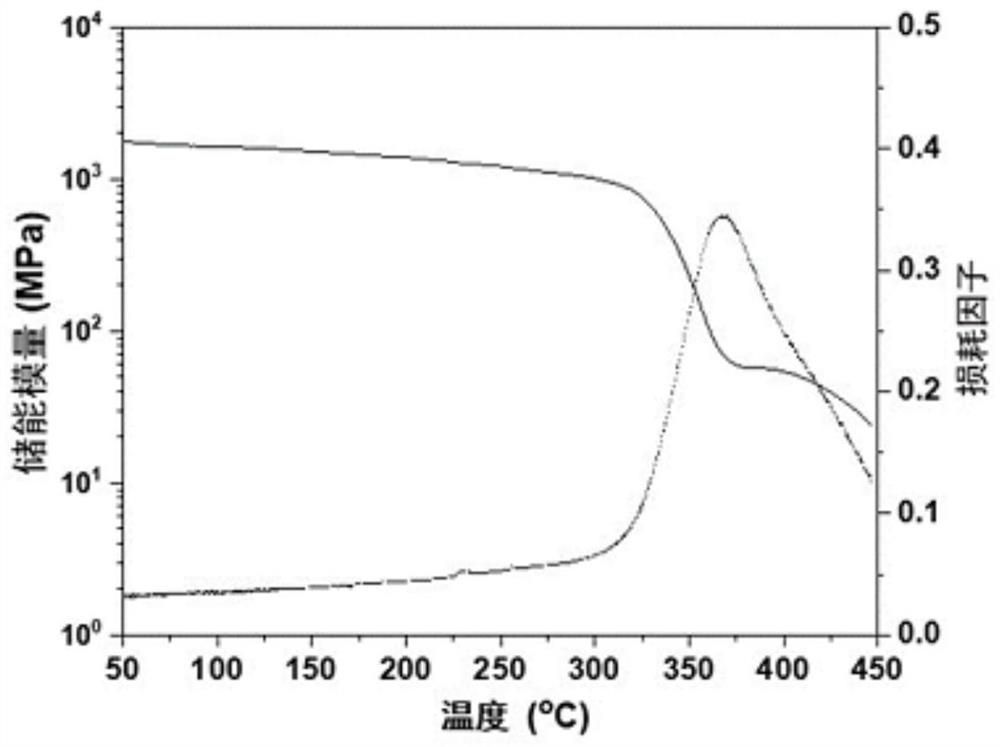

Thermoplastic polyimide with excellent comprehensive performance and preparation method and application thereof

The invention relates to thermoplastic polyimide with excellent comprehensive performance and a preparation method and application thereof, belongs to the technical field of polyimide, and solves the problem that good melting manufacturability and high heat resistance of existing thermoplastic polyimide are difficult to achieve at the same time. The thermoplastic polyimide is prepared from the following raw materials: fluorine-containing aromatic dianhydride, m-phenylenediamine, rigid aromatic diamine with a large-volume structure and a non-reactive end-capping reagent. The preparation method comprises the following steps: preparing a polyamide acid solution, preparing a polyimide solution, preparing a polyimide suspension, and carrying out post-treatment to obtain the polyimide powder. The thermoplastic polyimide resin disclosed by the invention can be used as a high-temperature-resistant engineering plastic, composite material matrix resin or a composite material interlayer toughening component, and is applied to the fields of aerospace, automobile manufacturing, power and electric appliances, microelectronics and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

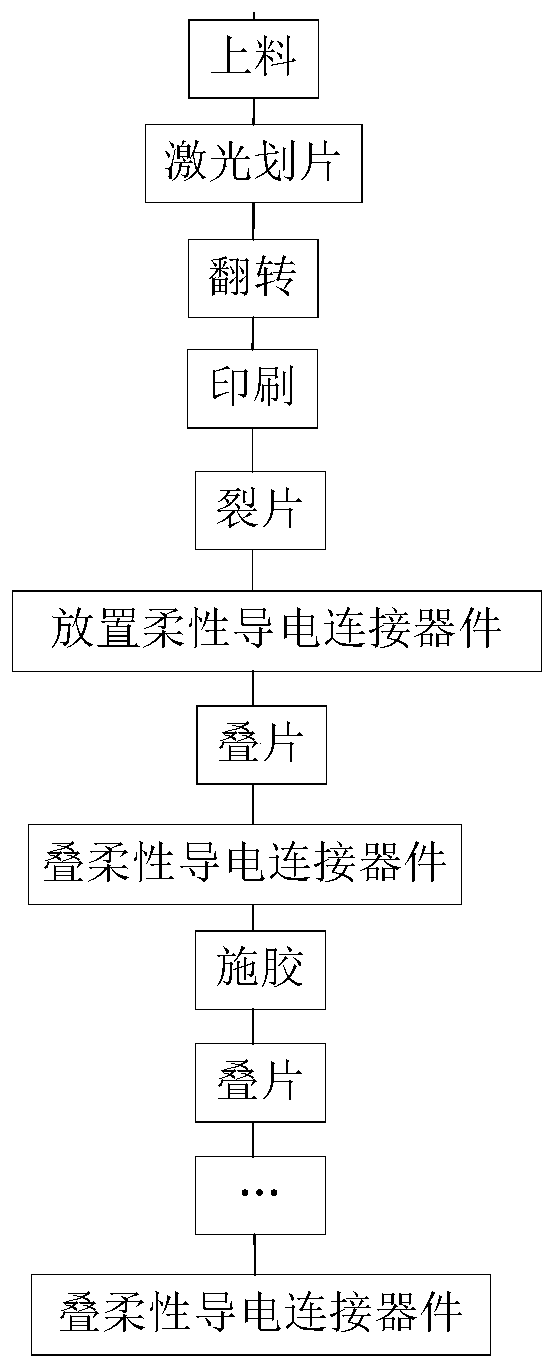

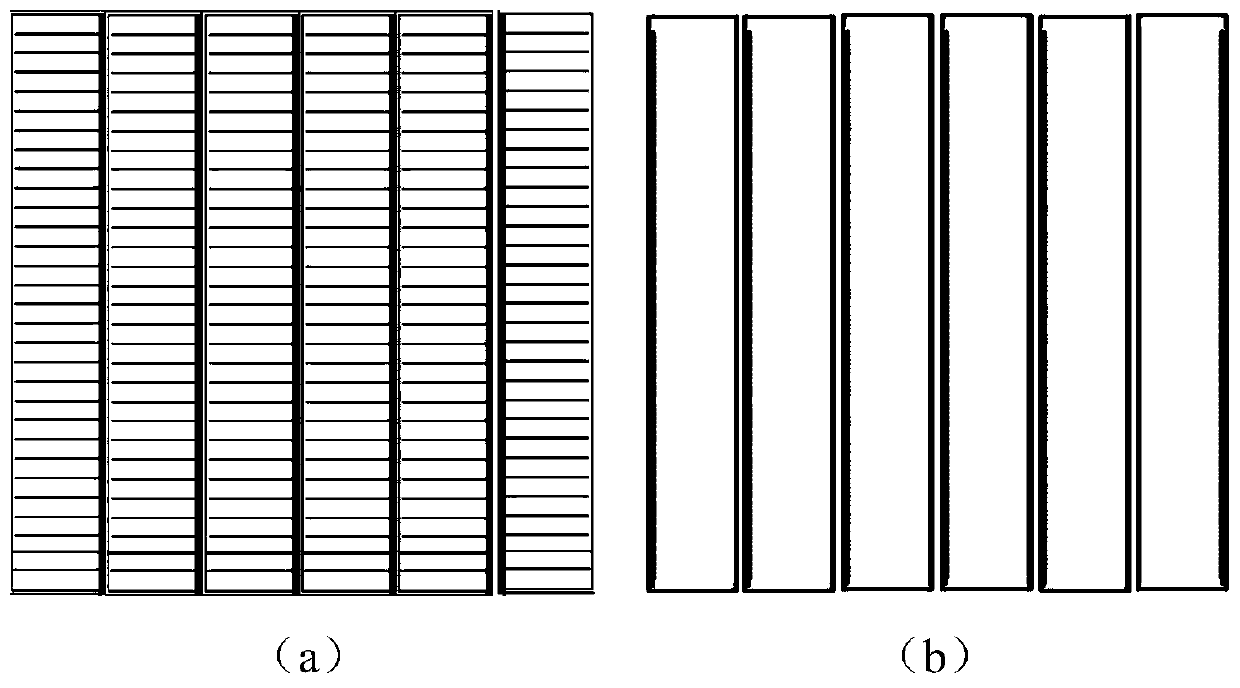

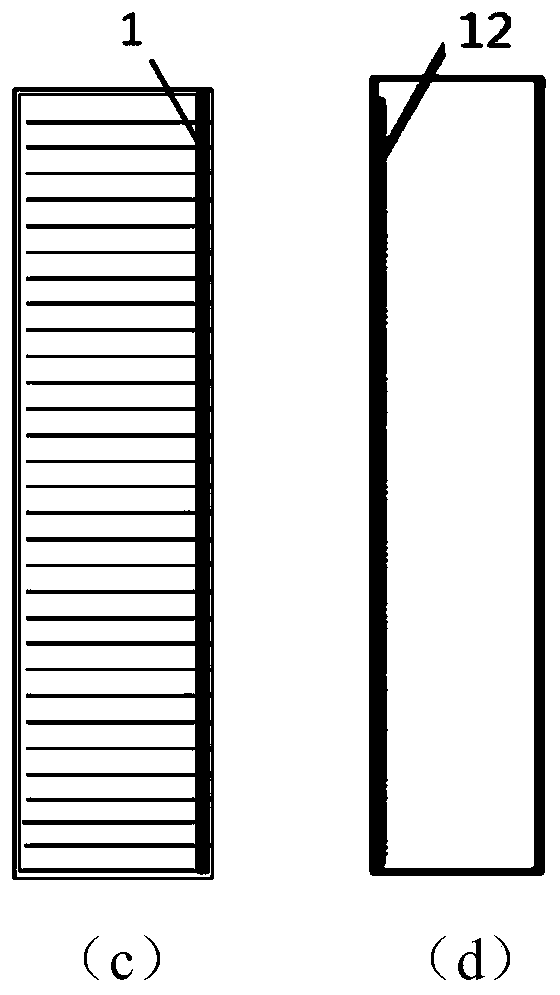

Combined battery string and manufacturing method thereof, and manufacturing method of battery assembly

ActiveCN111211192ARealize the combination designImprove reliabilityPhotovoltaic energy generationSemiconductor devicesSilver pasteProcess engineering

The invention relates to a combined battery string and a manufacturing method thereof, and a manufacturing method of a battery assembly, belongs to the technical field of solar batteries, and solves problems that in the prior art, in order to connect bypass diodes in parallel, a use amount of back silver paste needs to be increased, a battery design needs to be changed, and manual welding is needed so that production efficiency is low. The combined battery string comprises a plurality of battery pieces and a plurality of conductive connecting devices, and the plurality of conductive connectingdevices are located at two ends and in the middle of the combined battery string. The manufacturing method of the combined battery string comprises the following steps: manufacturing the conductive connecting devices and small battery fragments; applying a conductive adhesive to upper surfaces of the conductive connecting devices through CCD photographing and positioning; placing the small battery fragments on the conductive connecting devices; continuously placing the small battery fragments and connecting the small battery fragments in series to a certain number; stacking the conductive connecting devices; repeating the steps till that the small battery fragments reach the required number; and grabbing the conductive connecting devices to obtain the combined battery string. In the invention, low-cost and high-efficiency parallel connection of the bypass diodes is realized.

Owner:晶澳(扬州)新能源有限公司

Thermosetting polyimide resin, prepolymer, preparation method and application thereof

The invention relates to thermosetting polyimide resin, a prepolymer, a preparation method and an application thereof, belong to the technical field of thermosetting polyimide resin, and solve the problem that the glass-transition temperature of cured resin is relatively low while the existing polyimide resin prepolymer meets the requirements of an RTM (resin transfer molding) process. The polyimide resin prepolymer is prepared from aromatic dianhydride, rigid aromatic diamine, diamine containing a siloxane structure and an end-capping reagent. The preparation method of the thermosetting polyimide resin comprises the following steps: heating and melting the prepolymer; heating to 370-400 DEG C, curing for 1-2 hours, and cooling to obtain cured resin; and treating the cured resin at 400-450DEG C for 1-8 hours to obtain the thermosetting polyimide resin. According to the invention, RTM molding process requirements and high temperature resistance are both considered.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Sensitizer for radiotherapy and application thereof

ActiveCN114712500AGood biocompatibilityLow toxicityInorganic active ingredientsNanomedicineRadioactive agentOxygen deficiency

The invention relates to a sensitizer for radiotherapy and application thereof, belongs to the field of nanomaterial chemistry and biochemistry, and solves the problems that an existing radiotherapy sensitizer cannot improve the hypoxic state in a tumor microenvironment, radiotherapy is insensitive, the dosage of a radioactive agent is large, and damage to normal tissues is large. The sensitizer for radiotherapy comprises BiO2-x nanosheets, the molecular structure has oxygen deficiency, and the sensitizer is prepared from the following raw materials: hydroxide of alkali metal and bismuthate; and x ranges from 0.15 to 0.6. The preparation method comprises the following steps: dissolving hydroxide of alkali metal and bismuthate, and stirring to obtain a solution; transferring the solution into a reaction container, heating, and reacting for a period of time; and cooling to room temperature, washing with deionized water, and drying at 60-100 DEG C for 2-8 hours to obtain BiO2-x. The BiO2-x disclosed by the invention can be used as a sensitizer to be applied to radiotherapy sensitization of tumors, and a very good inhibition effect on the tumors under a relatively low radiation dose is realized.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

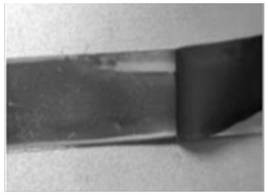

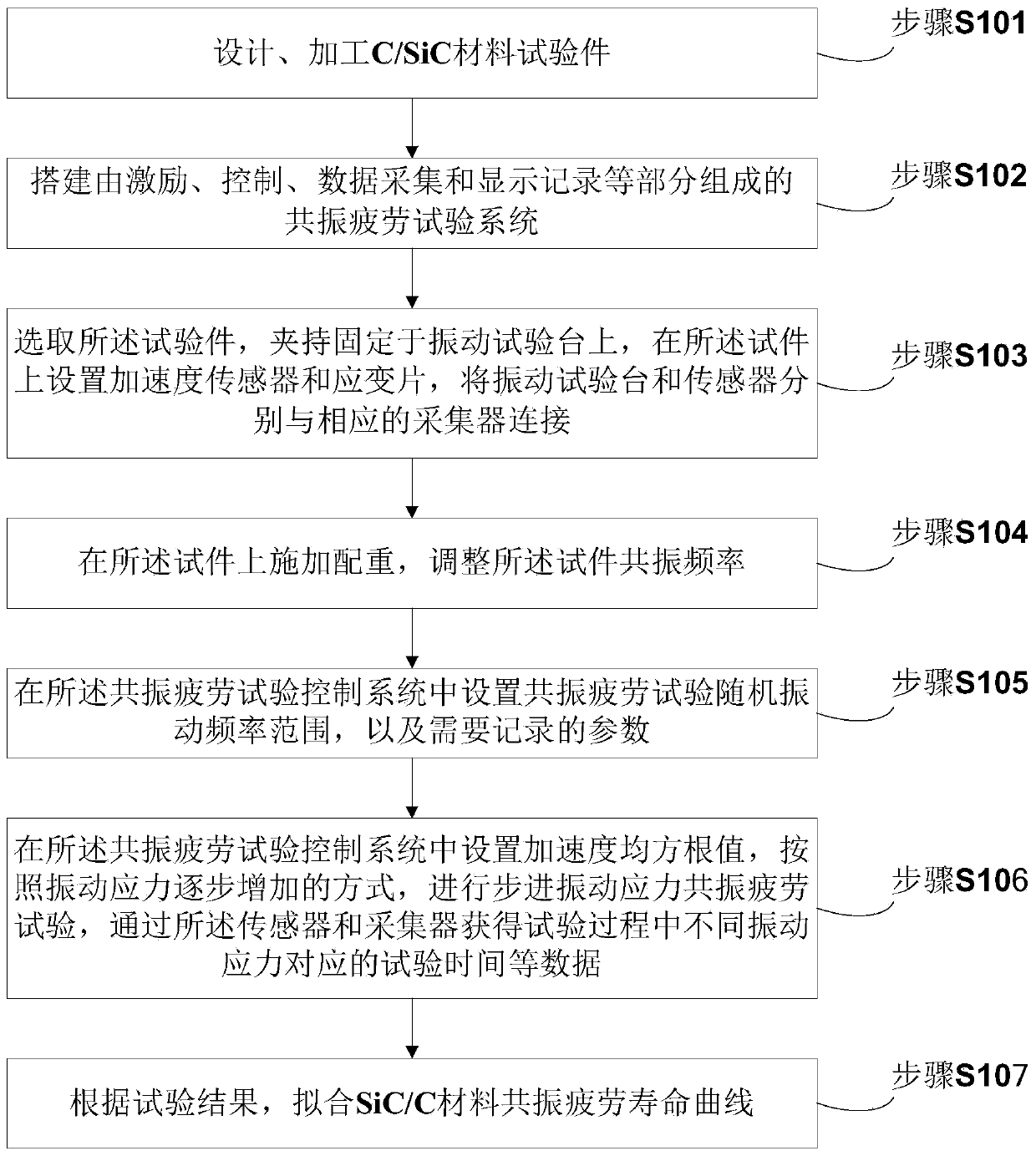

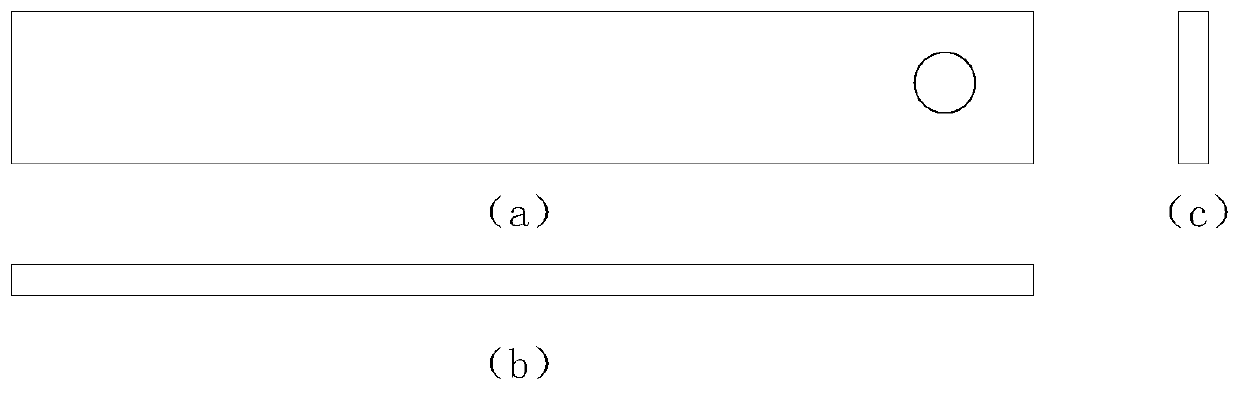

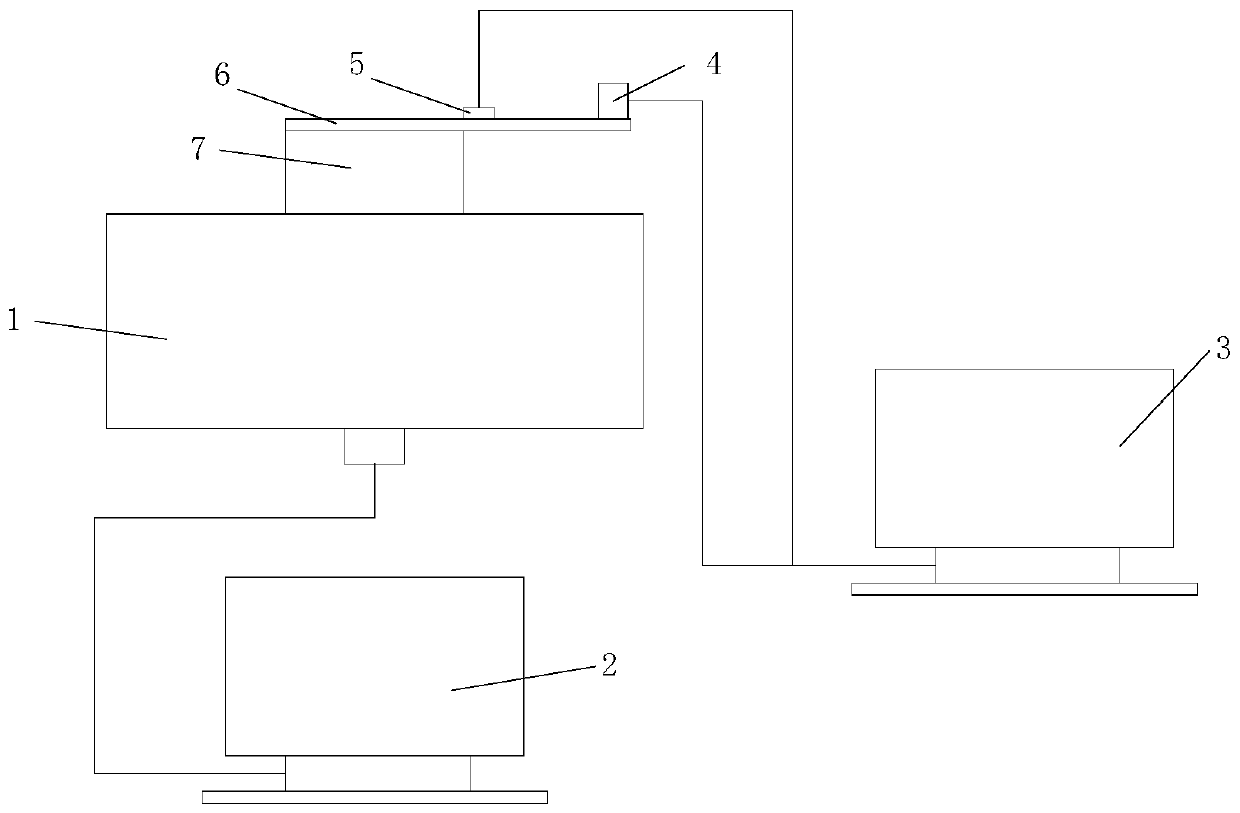

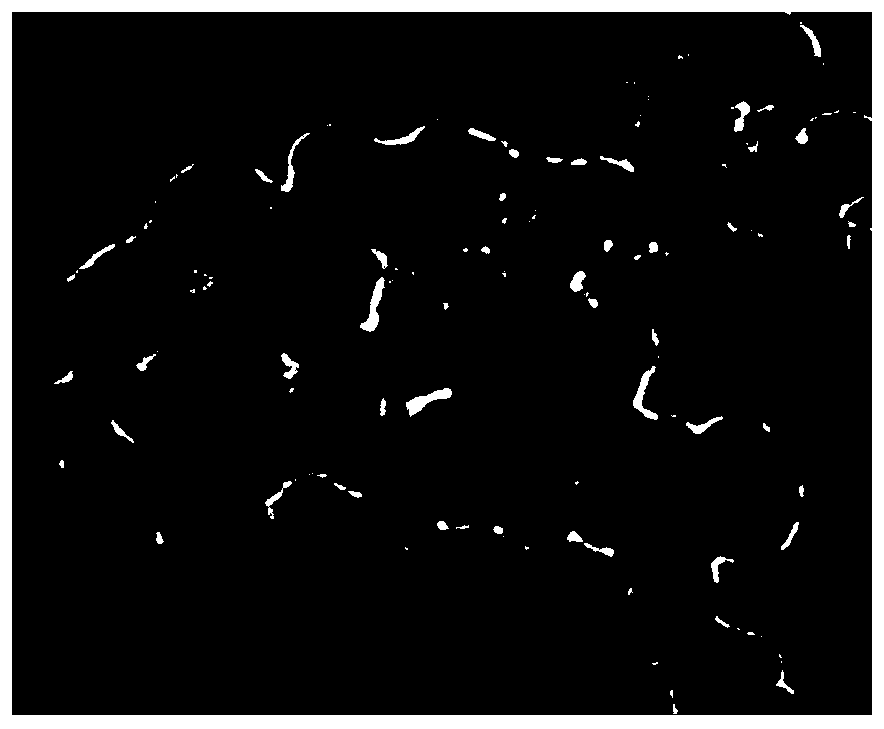

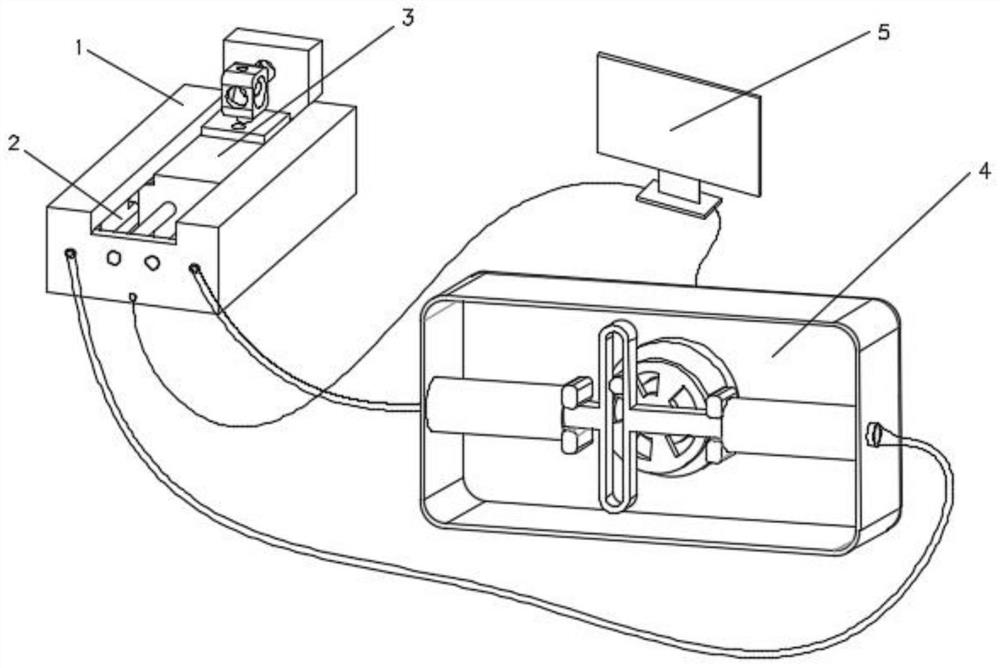

Stress resonance fatigue test method and test system for lightweight high-strength composite material

ActiveCN110927249AAccurately generate resonance fatigue failure dataImprove accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using repeated/pulsating forcesFatigue damageControl system

The invention relates to a stress resonance fatigue test method and a test system for a lightweight high-strength composite material. The invention belongs to the technical field of composite materialresonance fatigue tests. The problems that in the prior art, fatigue damage caused by response of static response analysis to the structure under dynamic excitation is difficult to obtain a more accurate conclusion, and no resonance fatigue test method and test system for the light-weight high-strength composite material and the structure exist are solved. The test method comprises the followingsteps: applying a counterweight, and adjusting the resonant frequency; setting a random vibration frequency range and parameters needing to be recorded; and setting an acceleration root-mean-square value, carrying out a test in a mode of gradually increasing the vibration stress level, and fitting a fatigue life curve. The test system comprises a vibration test bench, a data acquisition and display recording system, a resonance fatigue test control system and an induction part. The method has important guiding significance for further expanding to C / SiC and other composite material structure resonance fatigue tests.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

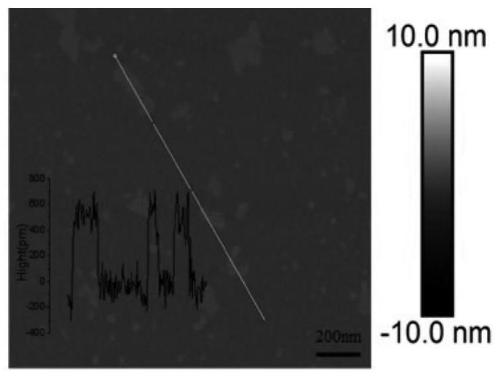

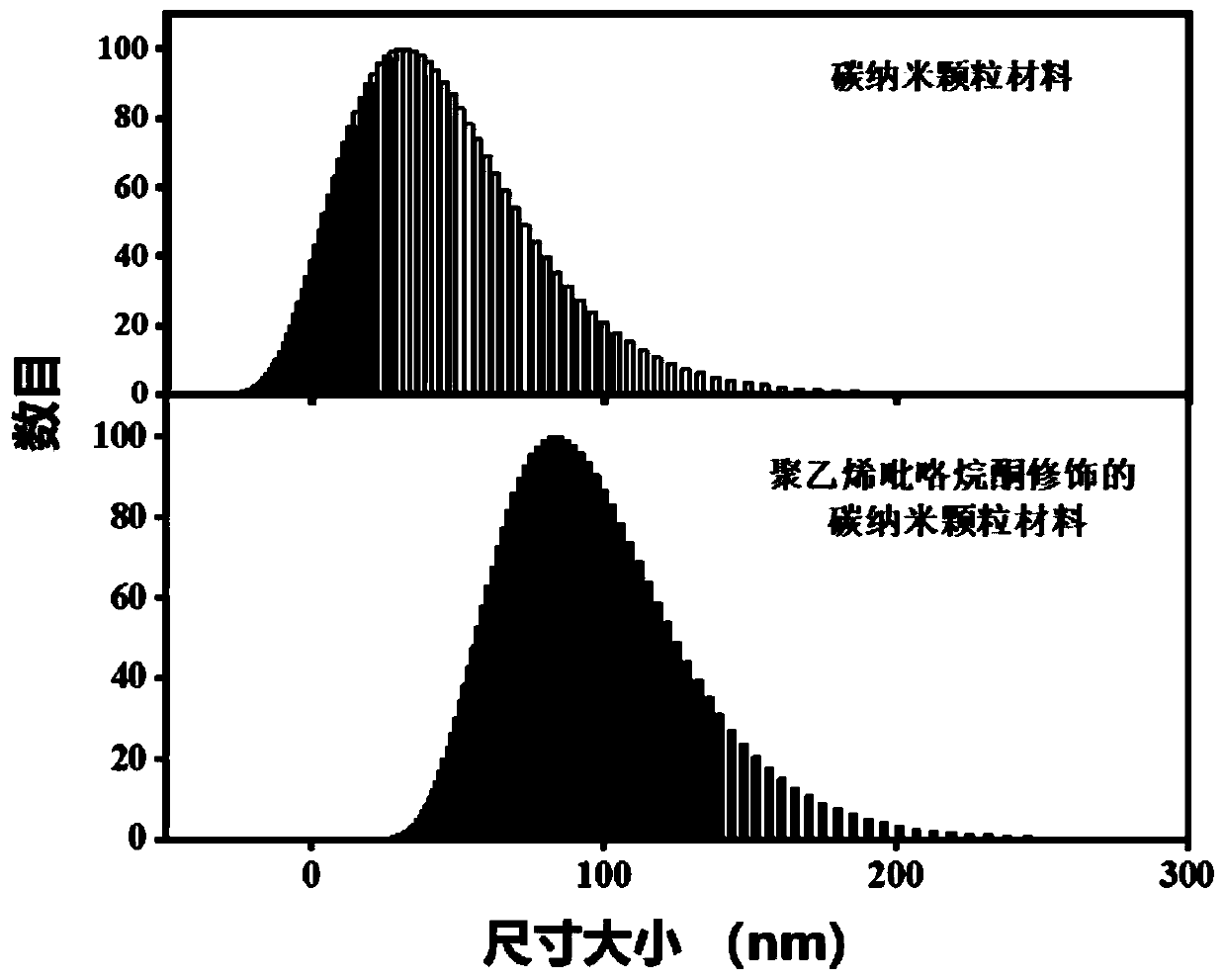

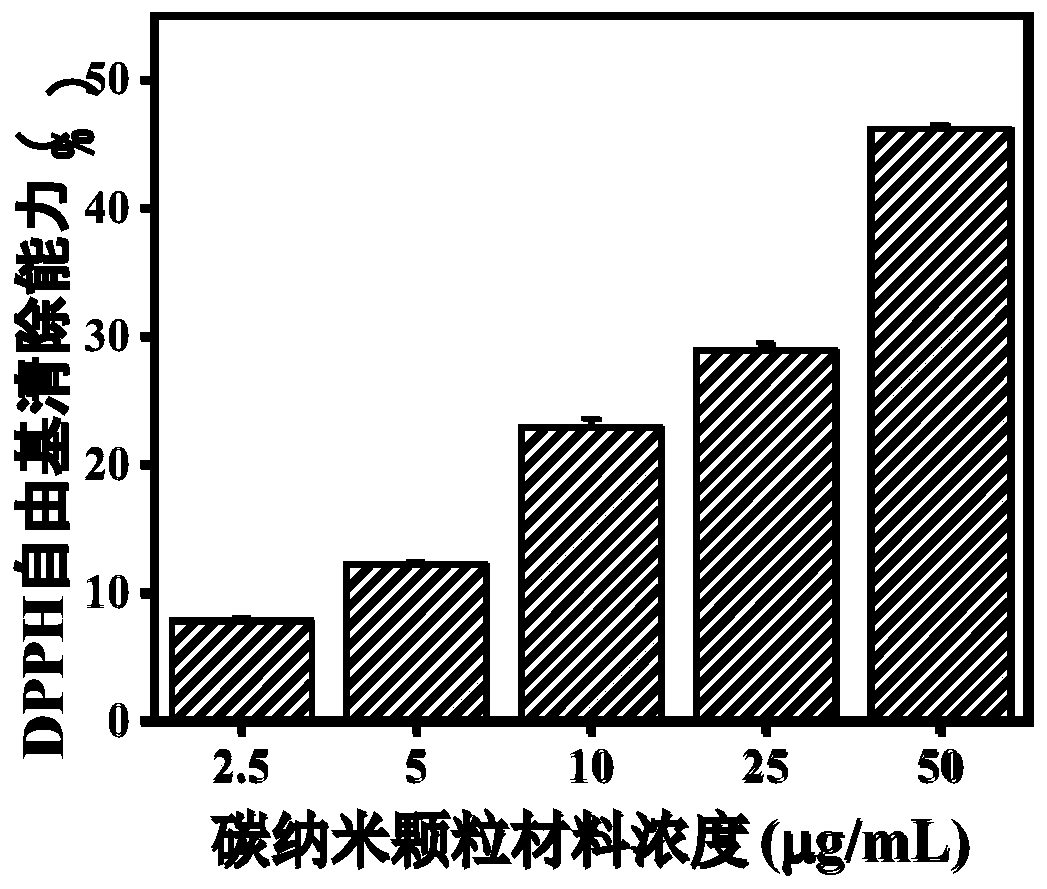

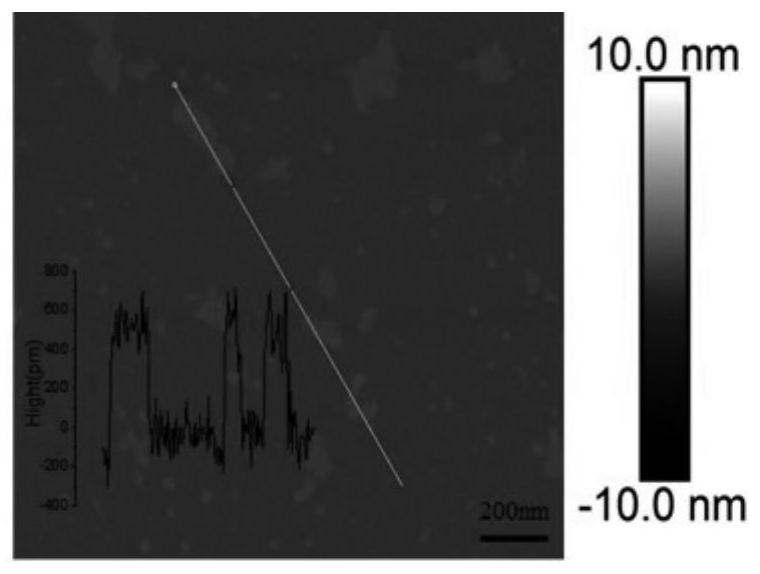

Carbon nanoparticles for scavenging free radicals as well as preparation method and application thereof

ActiveCN111012800AEfficient captureEfficient removalCarbon active ingredientsAntinoxious agentsCarboxyl radicalPharmaceutical drug

The invention relates to carbon nanoparticles for scavenging free radicals as well as a preparation method and application of the carbon nanoparticles, belongs to the technical field of nano materials, free radical scavenging and radiation protection, and can solve the problems that an existing drug for radiotherapy protection is fast in degradation in vivo, short in drug effect time, incapable ofwell targeting gastrointestinal tracts and large in toxic and side effects. The carbon nanoparticle for scavenging free radicals has a graphene-like structure and contains hydrophilic groups such ascarboxyl and hydroxyl; the hydration particle size of the carbon nanoparticles is 15-25 nm. The preparation method of the carbon nanoparticles comprises the following steps: adding an oxidant into a carbon raw material for oxidation; refluxing for 5 to 24 hours at 85 to 95 DEG C; cooling to room temperature, centrifuging, discarding a precipitate, and reserving a supernatant; and centrifuging thesupernatant, and washing an obtained precipitate product to obtain the carbon nanoparticles. According to the invention, safe and efficient radiotherapy protection on gastrointestinal tracts is realized.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

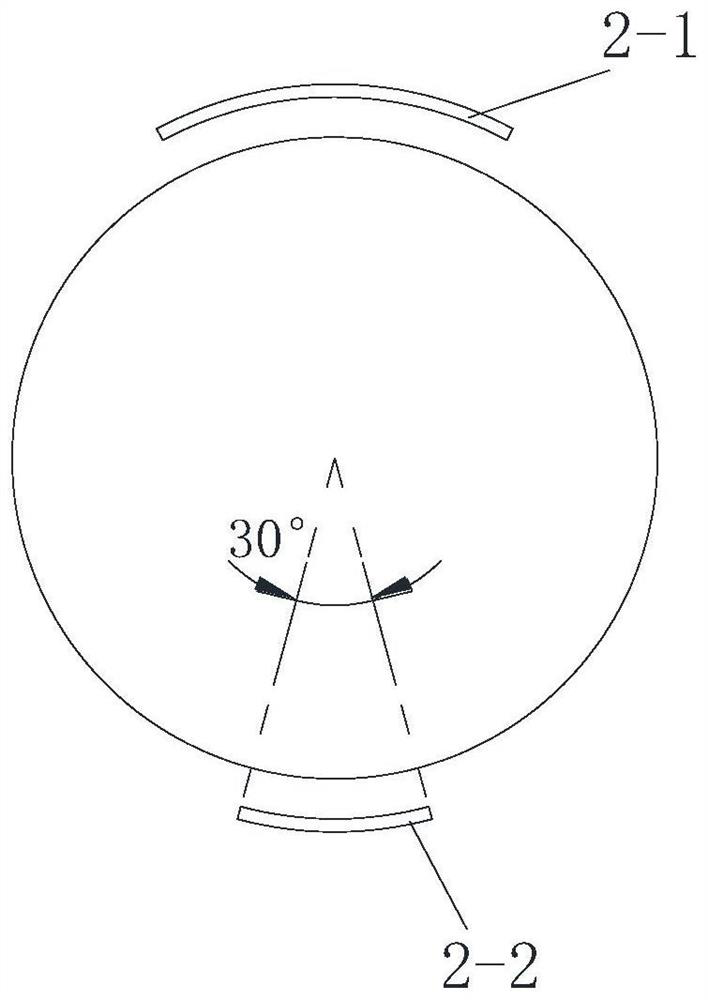

CT imaging system and imaging method

PendingCN114280087AReduce the number of layoutsComplete projection dataMaterial analysis using wave/particle radiationNuclear radiation detectionRadiologyRadiation imaging

The invention relates to a CT imaging system and an imaging method, belongs to the technical field of radiation imaging, and solves the problem that an existing CT system adopting static CT equipment needs a large number of radiation sources and detectors. The CT imaging system comprises a static imaging subsystem, a dynamic imaging subsystem and a rack, the static imaging subsystem and the dynamic imaging subsystem are both fixed to the rack, and the static imaging subsystem comprises multiple sets of static imaging units which are fixedly arranged. By fusing the static imaging subsystem and the dynamic imaging subsystem, the arrangement number of ray sources and detectors in static CT can be reduced, relatively complete projection data can be obtained in a data fusion mode, the quality of reconstructed images is improved, and relatively complete and ideal overall reconstruction results are obtained.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Etching method and etching gas for inner-side wall, and preparation method for nanowire device

ActiveCN110938434AImprove the selection ratioFacilitate control of etch morphologySemiconductor/solid-state device manufacturingSurface treatment compositionsPhysicsRadio frequency

The invention relates to an etching method and etching gas for an inner-side wall, and a preparation method for a nanowire device, belonging to the technical field of semiconductors. The invention solves the problem of incapability of simultaneously realizing reservation of a side-wall material in a groove and high selection ratio of materials like silicon and a top-part hard mask in the prior art. The gas used for etching the inner-side wall of the nanowire device comprises CH2F2, CH4, O2 and Ar, wherein the ratio of the CH2F2 to the CH4 to the O2 to the Ar is 1: 1: 1: 2 to 1: 1: 1: 5; in theetching process, an upper radio frequency power is in a range of 100-1000 W, and a lower radio frequency power is in a range of 10-80 W; the power of a lower electrode is 0-60 W; and the temperatureof a base is minus 20 DEG C to 90 DEG C. The preparation method for the nanowire device comprises the following steps: extending a lamination layer and a hard mask on a substrate; transversely etchingan SiGe layer so as to form a filling gap with a preset length; depositing an inner-side wall material; and carrying out etching to remove the inner-side wall material outside the filling gap so as to form the inner-side wall. According to the invention, the side-wall material in the groove can be reserved, and high selection ratio of materials like the silicon and the top-part hard mask can be achieved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

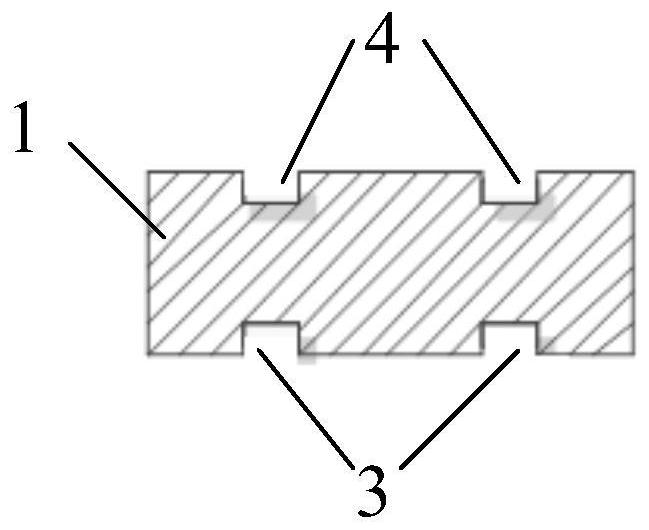

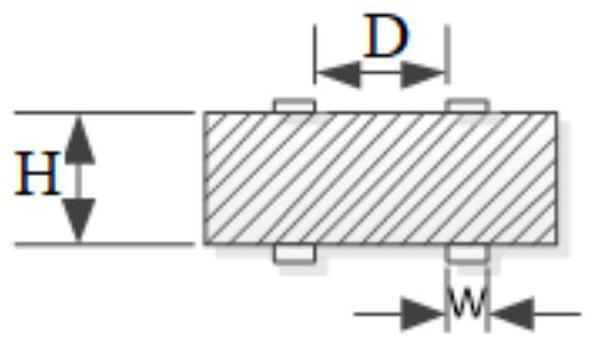

Manufacturing method of capacitive coupling type slip ring

PendingCN114156714AHigh communication rateIncrease the number of communication channelsSlip-rings manufactureCapacitanceChannel data

The invention relates to a manufacturing method of a capacitive coupling type slip ring, belongs to the technical field of X-ray computed tomography (CT) imaging technology, and solves the problems that the equipment size is increased and the cost is high due to the fact that the communication rate of the whole system is increased by widening the width of a rotating disc of an existing slip ring. The manufacturing method of the capacitive coupling type slip ring comprises the following steps: step 1, selecting a disc body; 2, a first groove is formed in the periphery of the inner surface of the tray body; step 3, fixing the transmitting end data processing unit on the disk body; the transmitting antenna is fixed in the first groove. According to the invention, multi-channel data transmission is realized.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

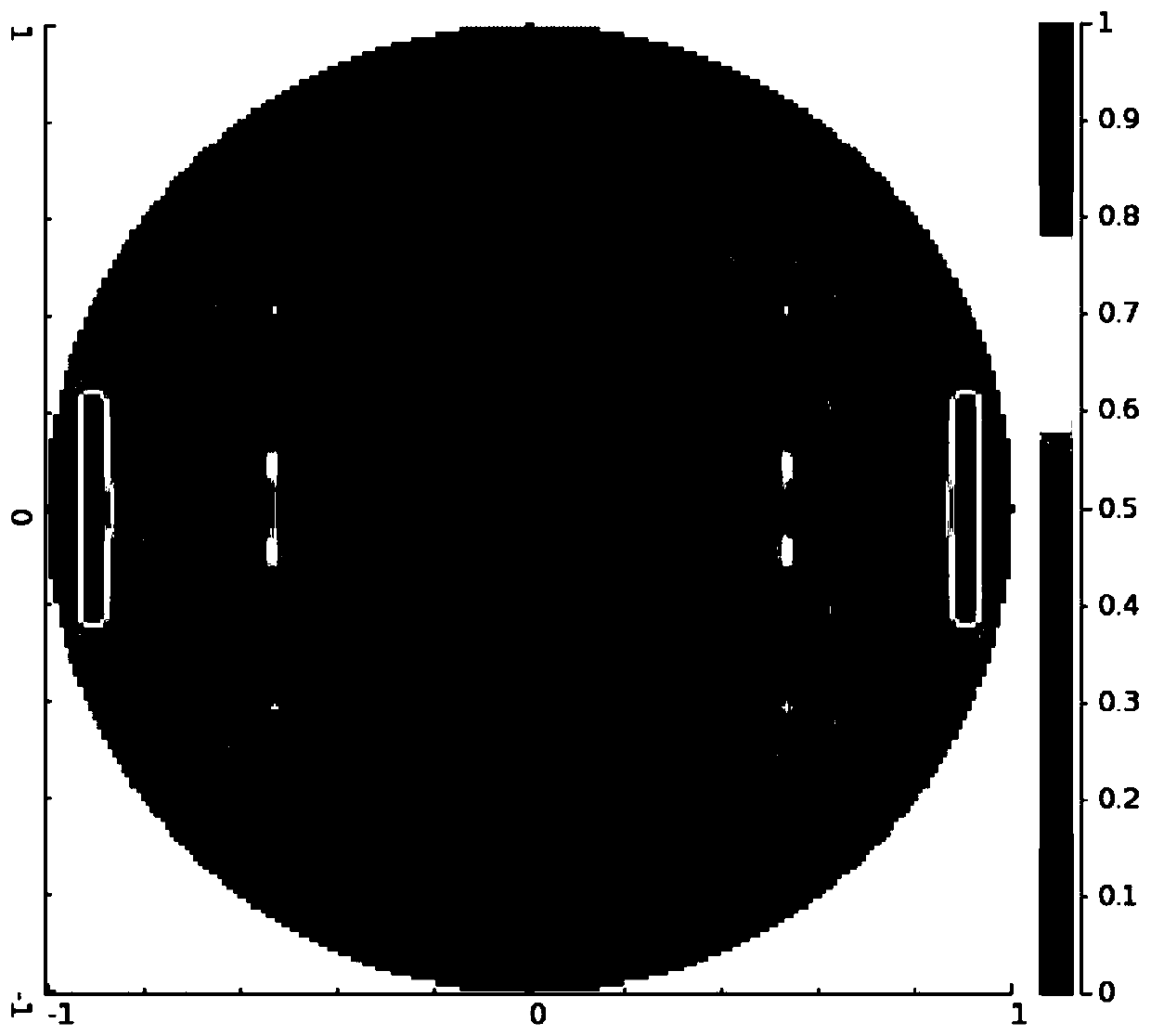

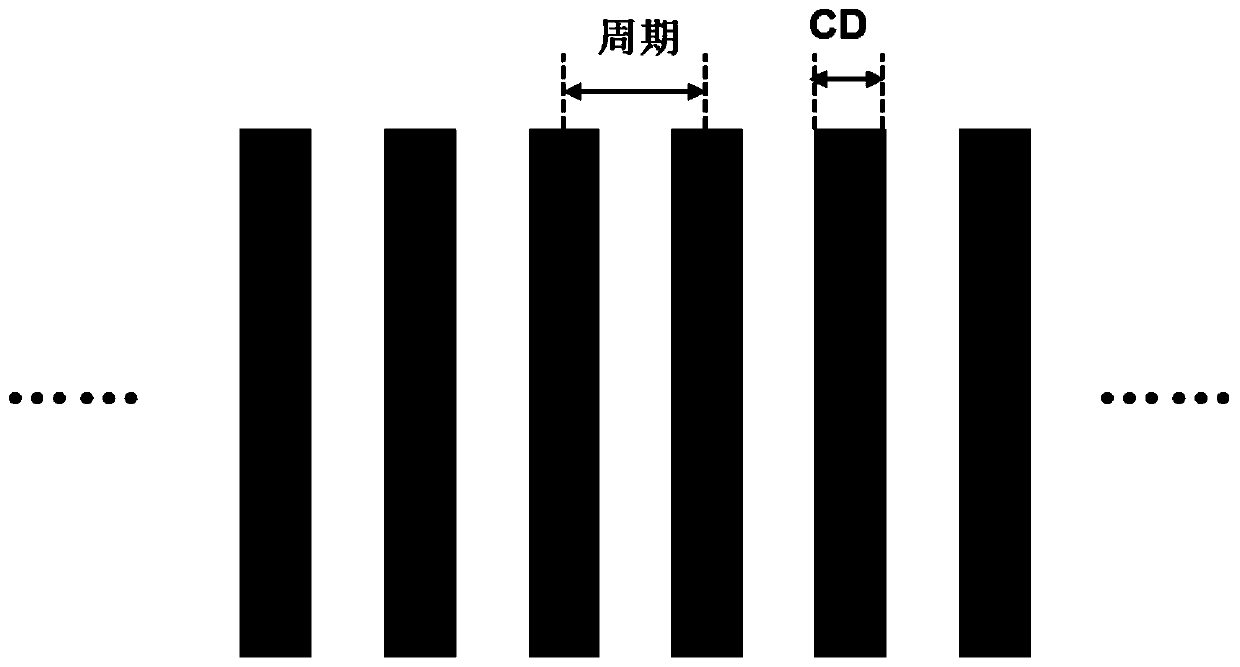

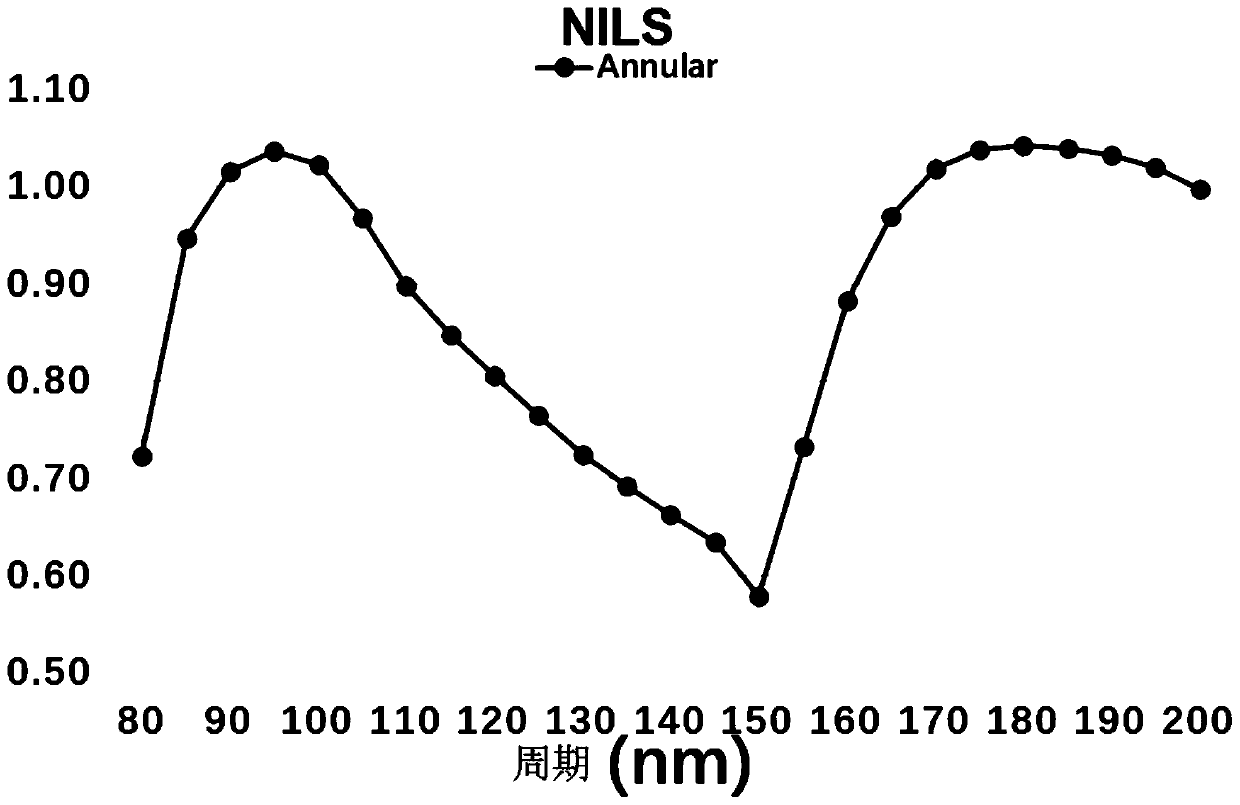

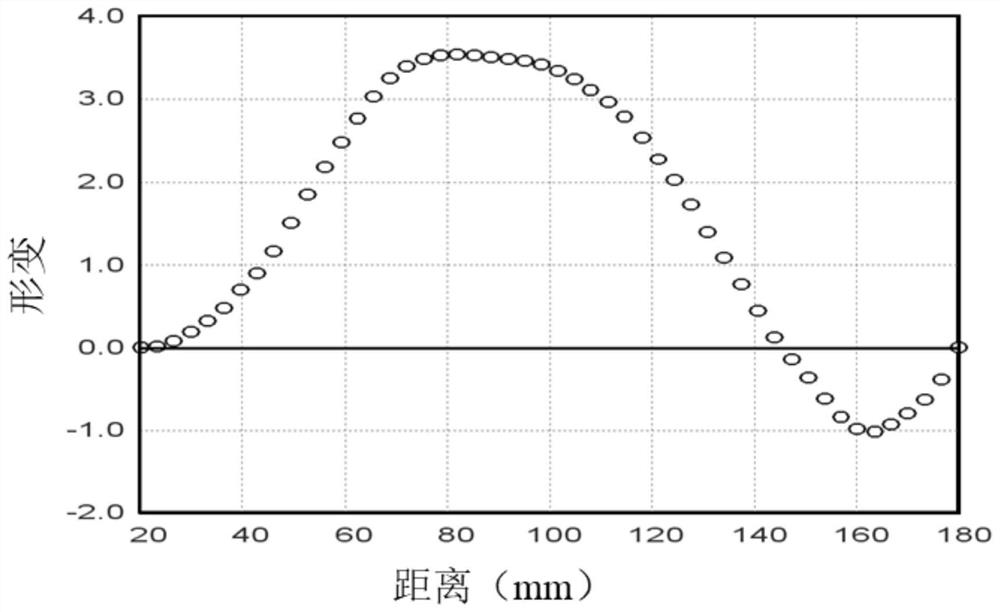

Method for determining prohibition period of photoetching process node and simulation method

ActiveCN111025856AProhibition period interval is clearMultiple preferred combinationsPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsLithography process

The invention relates to a method for determining a prohibition period of a photoetching process node and a simulation method, belongs to the technical field of semiconductor photoetching, and solvesthe problems that the found prohibition period is inaccurate, layout design rules cannot be effectively guided to be formulated, and reasons of poor photoetching quality of individual graphs cannot bejudged in a photoetching stage. The method for determining the prohibition period of the photoetching process node comprises the following steps: acquiring a test pattern; setting a first light source and simulation parameters, and performing simulation by utilizing software; analyzing a simulation result, drawing a first curve, and finding out a period range (first period range) which is obviously lower than other values in the first curve; setting a second light source and light source parameters, and drawing a second curve; finding out a period range (second period range) which is obviously lower than other values in the second curve, and combining the second period range and the first period range to jointly determine a forbidden period range. According to the invention, the prohibition period under a technical node is simply, efficiently and accurately determined.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Wafer processing device and method

PendingCN114520161AImprove yield lossImprove product yieldSemiconductor/solid-state device manufacturingPhysicsProcess engineering

The invention relates to a wafer processing device and method, belongs to the technical field of semiconductor manufacturing, and solves the problems that in the prior art, cleaning is carried out after all wafer processes are completed, smoke generated in the semiconductor manufacturing process cannot be completely removed, and the wafer yield is lost. The wafer processing device comprises a process chamber, a transfer chamber and a cleaning system. The cleaning system is arranged in the wafer processing device, so that the wafer passing through the process chamber can directly enter the cleaning system to be cleaned. A transfer mechanical arm is arranged in the transfer chamber, and the transfer mechanical arm completes the transfer of the wafer between the process chamber and the transfer chamber and between the transfer chamber and the cleaning system. The wafer processing method comprises the steps that after each process capable of generating smoke is carried out, the wafer is conveyed into the cleaning system to be cleaned and dried. According to the invention, the flue gas is effectively removed, and the yield loss caused by the flue gas is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Folding control surface assembling method

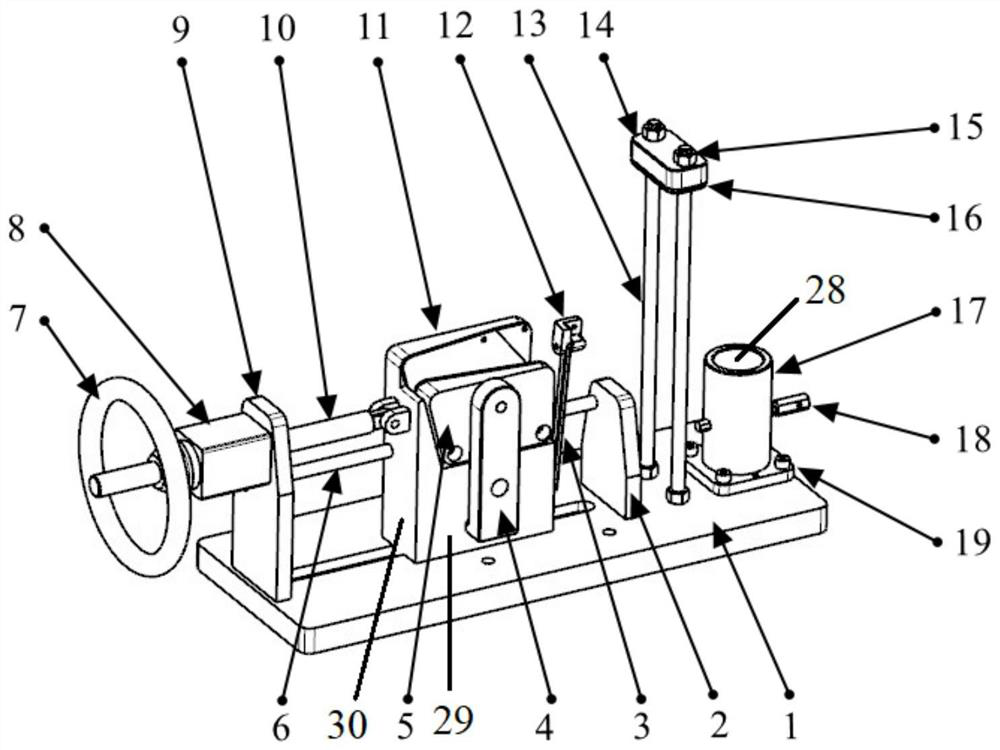

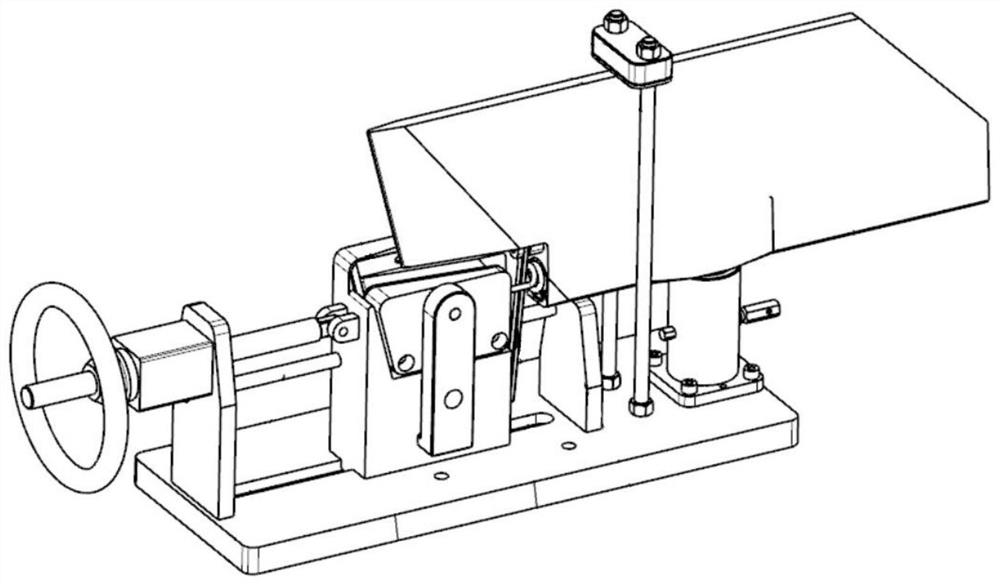

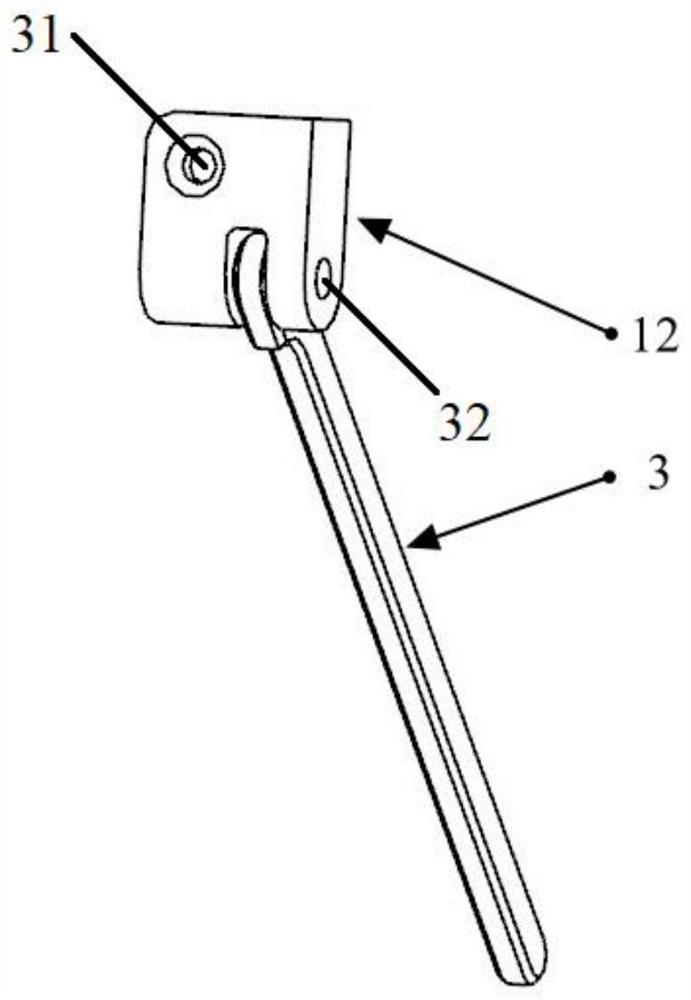

ActiveCN112659062AReliable lockingAvoid bumpingMetal-working hand toolsRelative motionTorsion spring

The invention relates to a folding control surface assembling method, belongs to the technical field of control surface assembling, and solves the problems that in the existing control surface assembling process, the pre-tightening force of a torsion spring is difficult to control and align, the positioning and clamping requirements of front and rear sections of a control surface are high, and the accessibility of manual operation in a narrow space is poor. The folding control surface assembling method comprises the steps that the front section of the control surface is positioned and clamped through a first positioning and clamping structure; a second positioning and clamping structure is adopted for positioning and clamping the rear section of the control surface; a torsion spring positioning piece is inserted into a mounting hole close to the front section of the control surface; a hand wheel lead screw is rotated, so that the control surface rear-section screw hole is aligned with a control surface front-section screw hole; and screws are installed, and installation of the control surface front section and the control surface rear section is completed. A folding control surface assembling tool comprises the first positioning and clamping structure, the second positioning and clamping structure, a torsion spring alignment structure and a directional driving mechanism. Positioning, clamping, relative movement and reliable locking of the front section and the rear section of the control surface are achieved.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

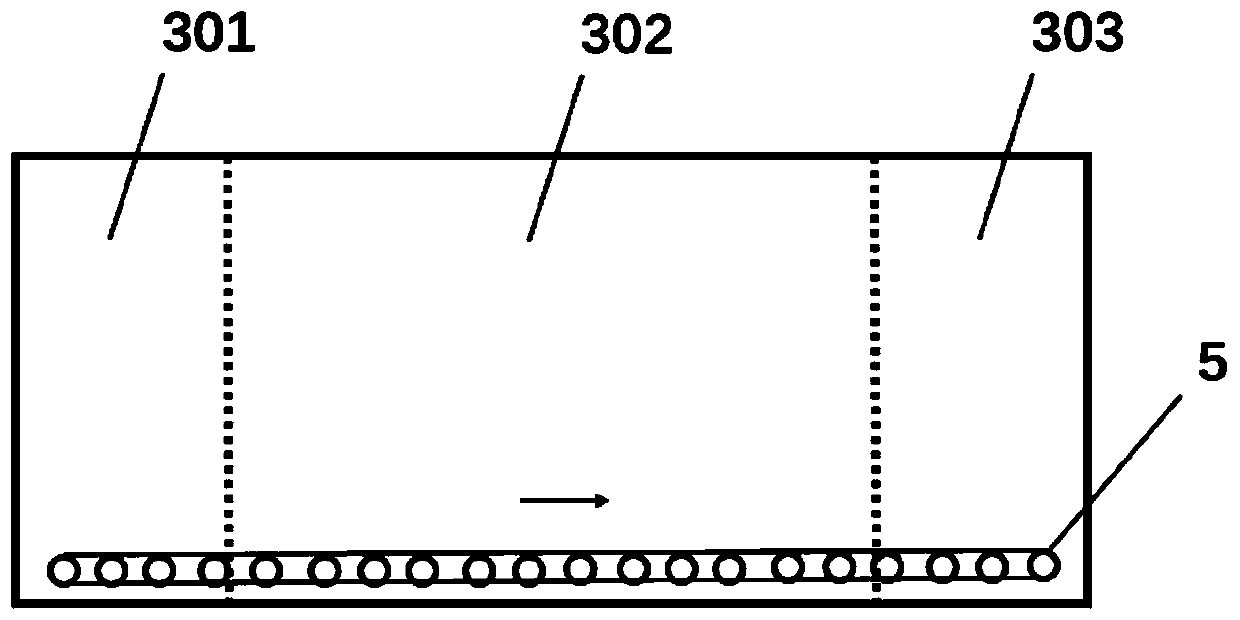

Plate type PECVD system integrated with anti-PID device and passivation film-coating method

InactiveCN111206239AReduce energy consumptionShorten passivation coating timeFinal product manufactureChemical vapor deposition coatingSolar cellBattery cell

The invention relates to a plate type PECVD system integrated with an anti-PID device and a passivation film-coating method, and belongs to the technical field of solar cell manufacturing. The problems that the passivation film-coating time is long and the temperature difference between a passivation bin and a PECVD process bin is large in an existing process, and debris is prone to being producedare solved. The plate type PECVD system integrated with the anti-PID device includes a feed bin, the anti-PID device, a PECVD process bin and a discharge bin; the anti-PID device includes a gas bottle, an induction device and a passivation bin; and the induction device can induce O2 to produce O3 at a normal temperature. The passivation film-coating method includes the steps that materials are preheated for the first time, and the materials enter the passivation bin; oxygen is introduced, the induction device is started, and a passivation film is formed on the surface of the materials; the materials is preheated for the second time in a heating area; and the materials pass through a film-forming process area and a cooling area. According to the plate type PECVD system integrated with theanti-PID device and the passivation film-coating method, the SiO2 passivation film is formed at the normal temperature.

Owner:JA SOLAR TECH YANGZHOU

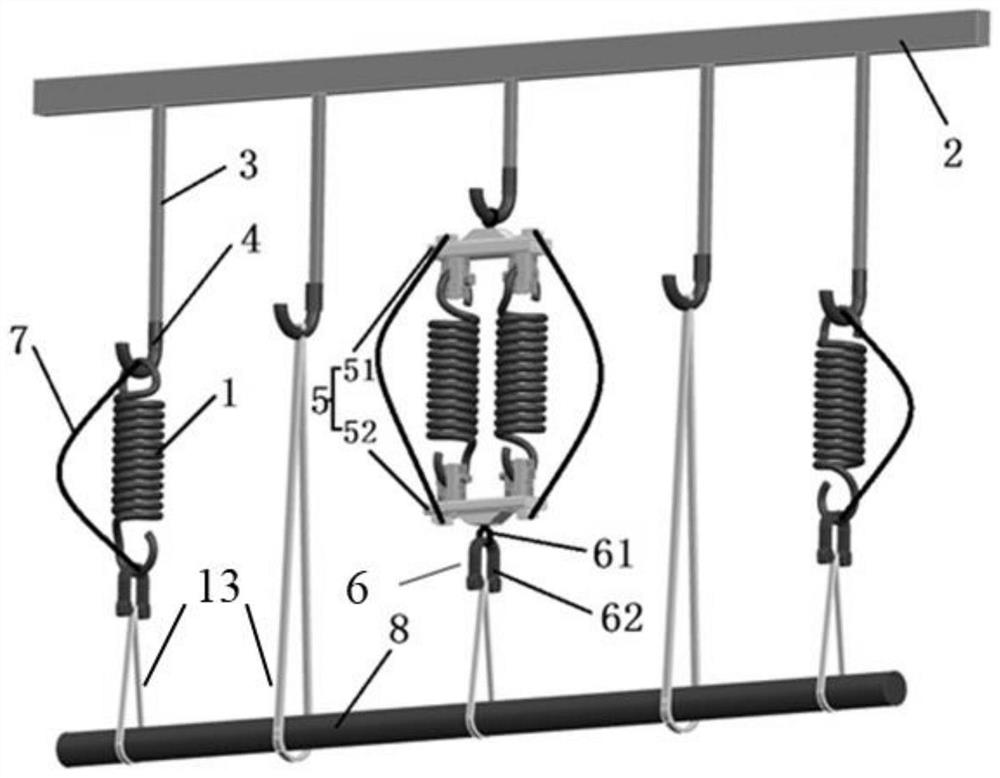

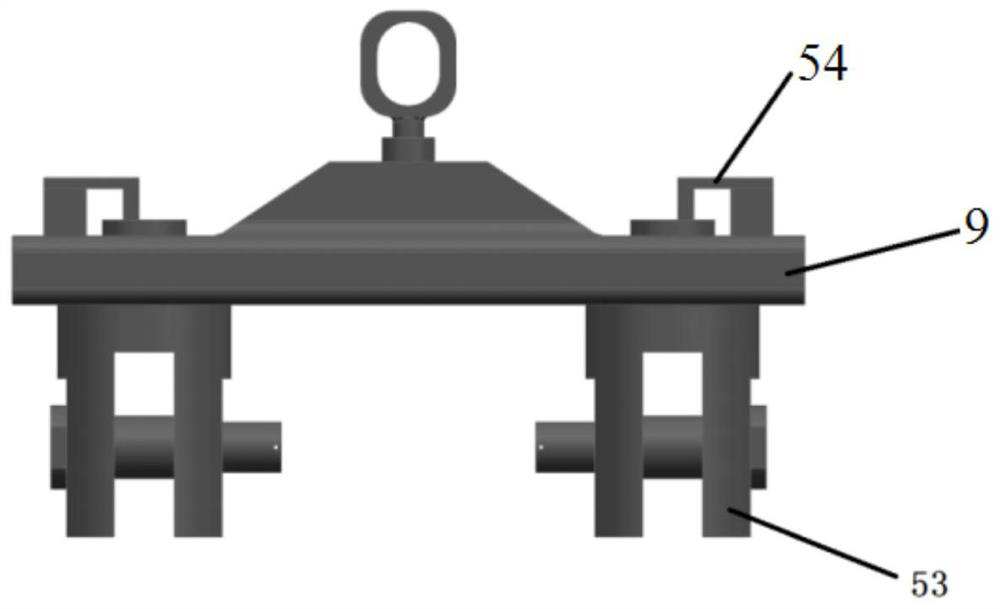

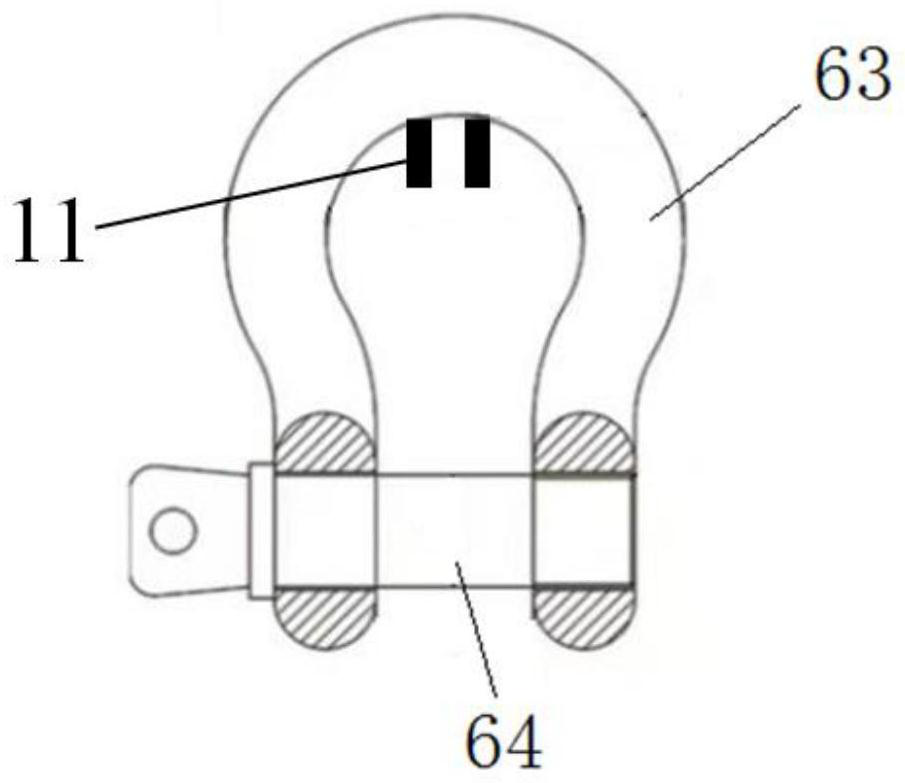

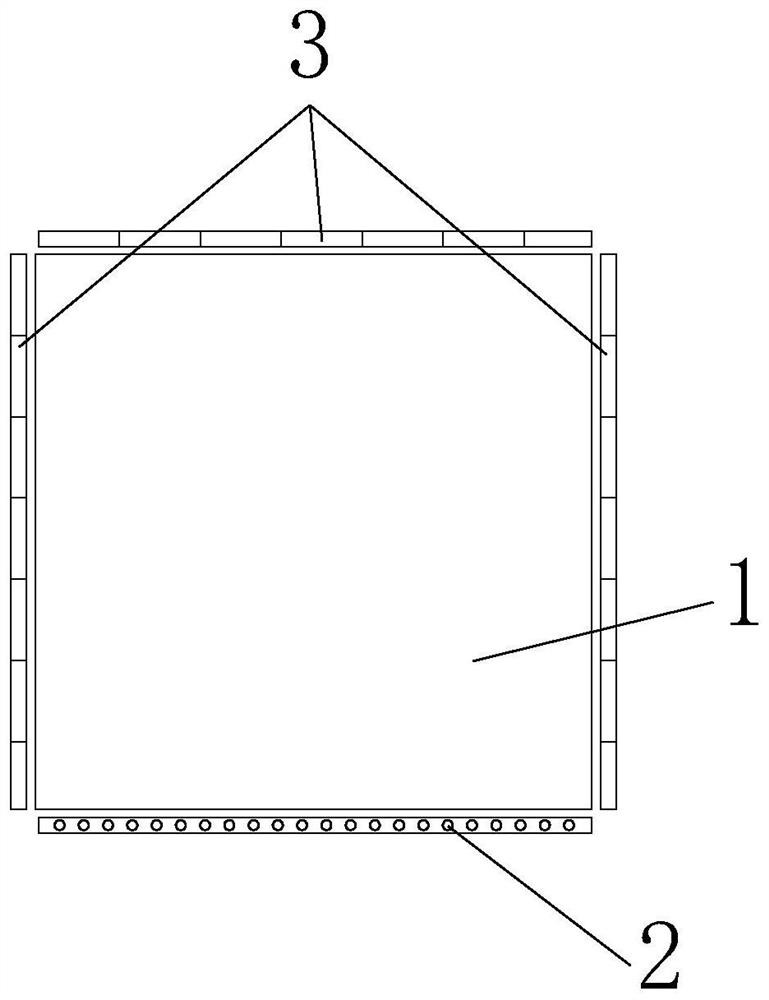

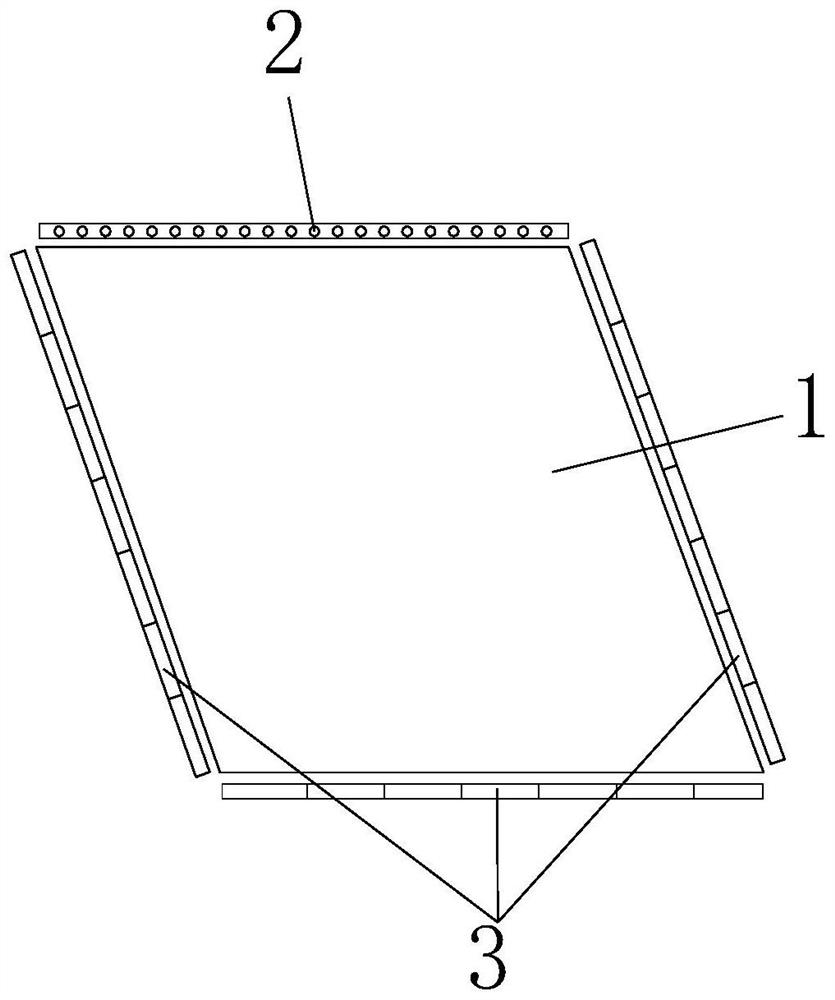

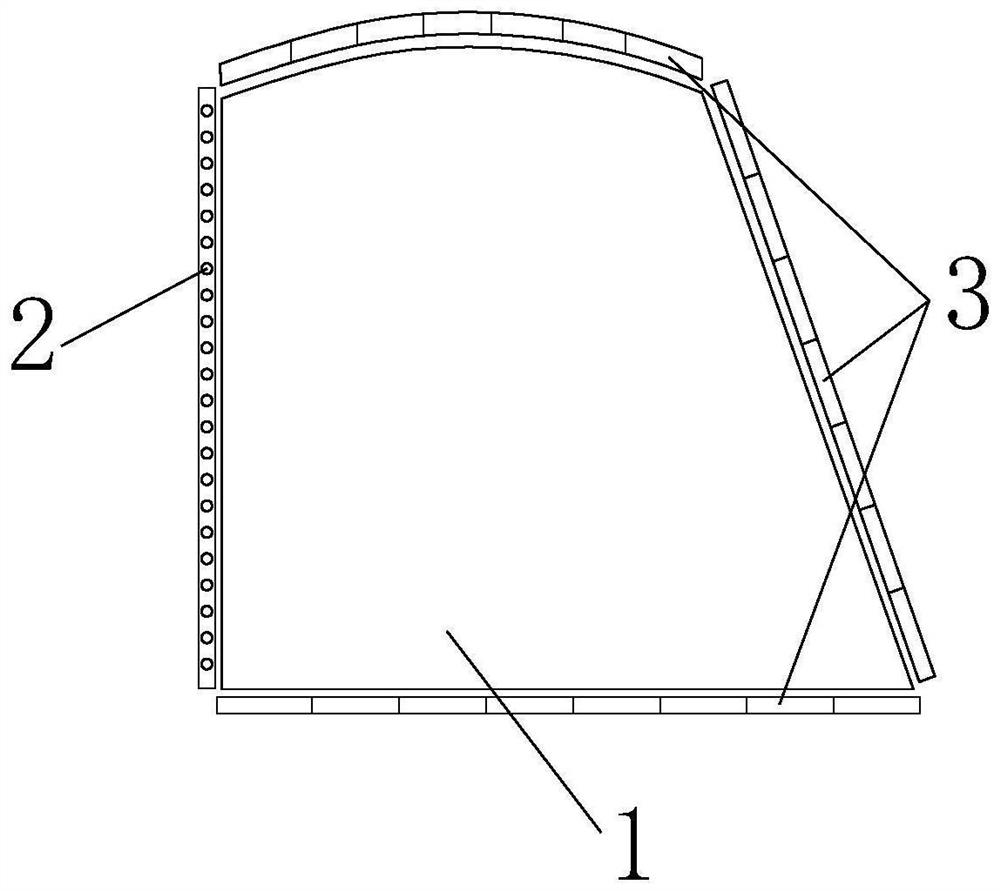

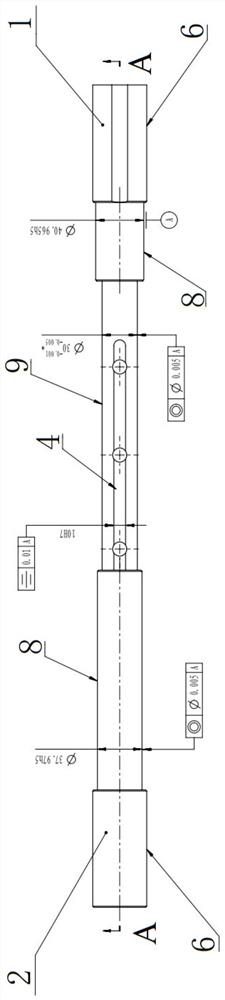

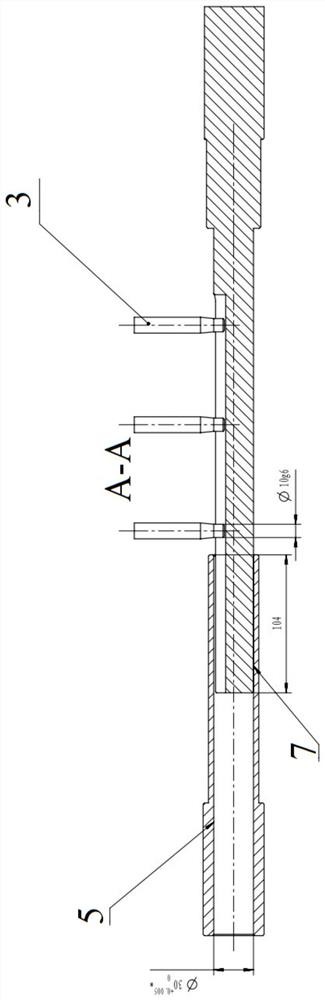

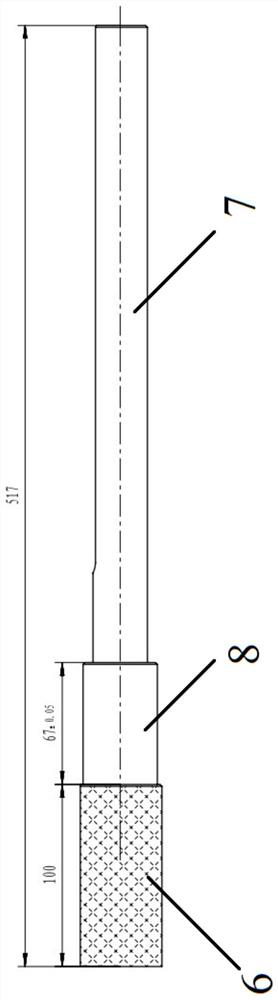

Modal test suspension device and modal test system

PendingCN114216668AIncrease flexibilityIncrease in sizeMachine part testingSUSPENDING VEHICLEAir spring

The invention relates to a modal test suspension device and a modal test system, belongs to the technical field of modal test parameter measurement, and solves the problems of complex operation and small application range of an air spring in modal test boundary condition simulation in the prior art. A modal test suspension device comprises: a suspension assembly; the suspension assembly comprises a plurality of steel springs, and the technical parameters of the steel springs are determined according to the weight and fundamental frequency of the test piece; the multiple steel springs are arranged in parallel, and at least one set of steel springs is formed by connecting the multiple steel springs in parallel. The device also comprises a crane crossbeam, the crane crossbeam is connected with a plurality of lifting chains, and each steel spring and each group of steel springs respectively suspend the test piece on the lifting chains through lifting hooks. According to the invention, the suspension assembly is arranged and the test piece is suspended on the suspension assembly, so that high-precision parameter measurement of a modal test of the test piece with relatively large size, weight and low fundamental frequency can be facilitated.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

A kind of sensitizer for radiotherapy and its preparation method and application

ActiveCN111035761BGood biocompatibilityLow toxicityInorganic active ingredientsNanomedicineNormal tissueBiology

The invention relates to a sensitizer for radiotherapy and its preparation method and application, belonging to the field of nanomaterial chemistry and biochemistry, and solves the problem that the existing radiotherapy sensitizer cannot improve the hypoxic state in the tumor microenvironment, and radiotherapy is not sensitive , The amount of radiation dose is large, and the problem of large damage to normal tissues. The molecular formula of the sensitizer used in radiotherapy is BiO 2‑x , there are oxygen defects in the molecular structure, and the raw materials for the preparation of the sensitizer include alkali metal hydroxides and bismuth salts. The preparation method of the sensitizer comprises: dissolving alkali metal hydroxide and bismuth salt, stirring to obtain a solution; transferring the solution to a reaction container, heating, and reacting for a period of time. BiO of the present invention 2‑x It can be used as a sensitizer for radiosensitization of tumors, and achieves a very good inhibitory effect on tumors at a lower radiation dose.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

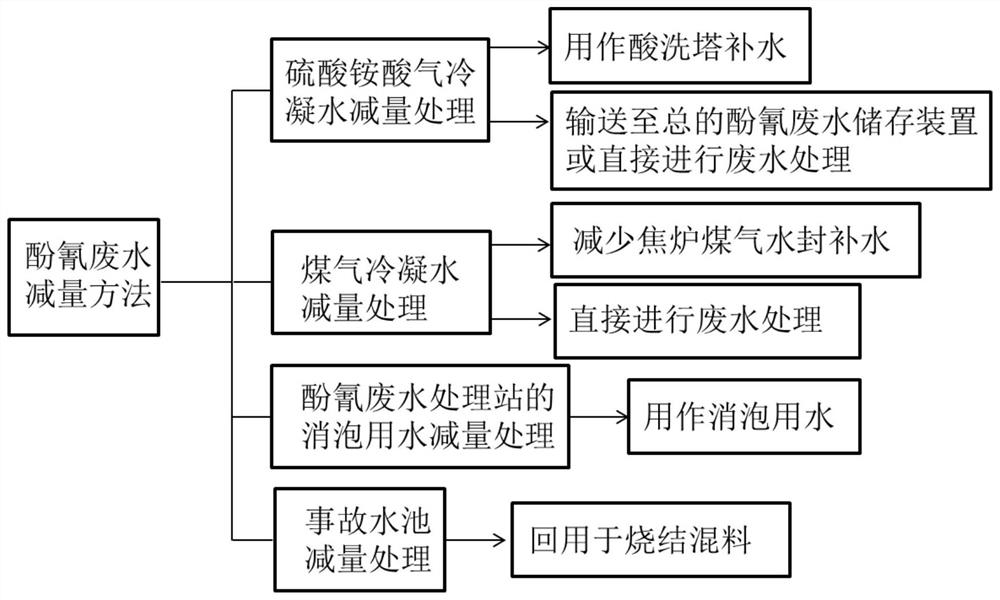

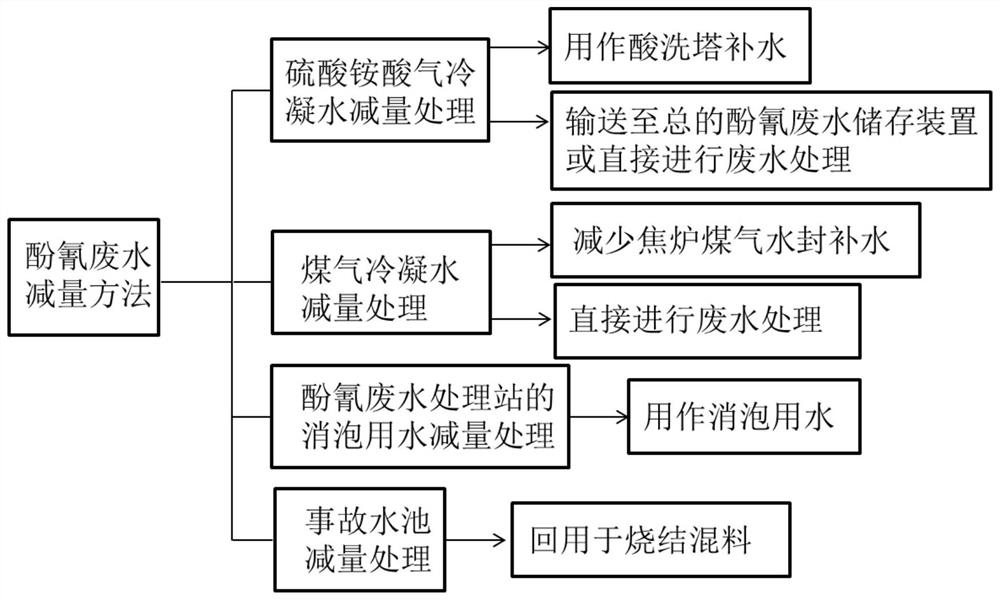

A method for reducing the amount of phenol cyanide wastewater

ActiveCN112939358BReduce delivery volumeAchieve reductionWater treatment parameter controlSpecific water treatment objectivesCyanidePhenol

The invention relates to a method for reducing the amount of phenol-cyanide wastewater, which belongs to the technical field of phenol-cyanide wastewater and solves the problem that there is currently no related technology for reducing the generation of wastewater from the source of phenol-cyanide wastewater, and the waste water produced in each link of the coking process is mixed with many types of pollutants. Handle difficult and high-volume problems. The reduction methods of phenol cyanide wastewater include the reduction treatment of ammonium sulfate acid gas condensate water, the reduction treatment of gas condensate water, the reduction treatment of defoaming water in the phenol cyanide wastewater treatment station and the reduction treatment of accident pools. The invention realizes reducing the production amount of phenol cyanide wastewater from the source.

Owner:内蒙古包钢集团环境工程研究院有限公司

A polyimide adhesive film with excellent comprehensive properties and its preparation method and application

ActiveCN113248708BImprove hot melt effectSmall dielectric lossFilm/foil adhesives without carriersDiphenyl etherPolymer science

The invention relates to a polyimide film with excellent comprehensive performance and its preparation method and application, which belongs to the technical field of polyimide and solves the problem of the excellent heat resistance and good adhesion of the existing polyimide film. Performance, low dielectric constant at high frequency and low dielectric loss are difficult to be compatible. The polyimide film is prepared from aromatic dianhydride, aromatic diamine containing diphenyl ether structure and diamine containing siloxane structure. The polyimide adhesive film has excellent heat resistance, high-frequency low-dielectric performance and good adhesion performance, the glass transition temperature is greater than 330 ° C, the dielectric constant at 10 GHz is less than 3, and the dielectric loss value is 0.003 Between ‑0.006, the peel strength after thermocompression bonding with copper foil is greater than 10N / cm, which can meet the application requirements of interlayer bonding and insulation in the manufacture of flexible printed circuit boards and multilayer circuit board laminated wiring processing, and can be widely used It is used in high-frequency flexible printed circuit boards, high-frequency film antennas and other fields.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Multi-view static CT system

PendingCN114324425AReduce volumeSimple structureMaterial analysis using wave/particle radiationNuclear radiation detectionRadiation imagingNuclear medicine

The invention relates to a multi-view static CT (Computed Tomography) system, belongs to the technical field of radiation imaging, and solves the problems that the existing static CT equipment needs to increase additional weight load in order to maintain the overall stability, so that the equipment is heavy and the size is too large. A multi-view static CT system includes: a transfer channel; imaging units with different visual angles are arranged in the conveying direction of the object, and the imaging units are arranged on the periphery of the conveying channel; the imaging unit comprises a radiation source and a detector assembly arranged corresponding to the radiation source. The imaging units with different visual angles are arranged in the object conveying direction, and the imaging units are arranged on the periphery of the conveying channel, so that static scanning imaging of the object can be completed in the advancing process of the object in the conveying channel, and CT imaging of the object at different visual angles is guaranteed.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

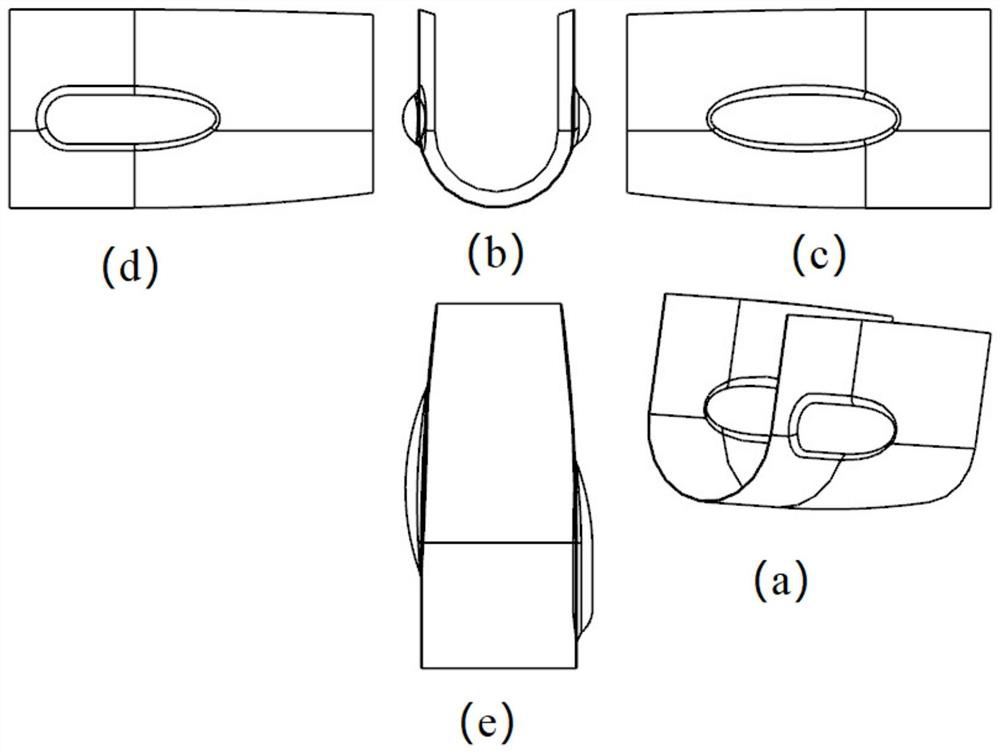

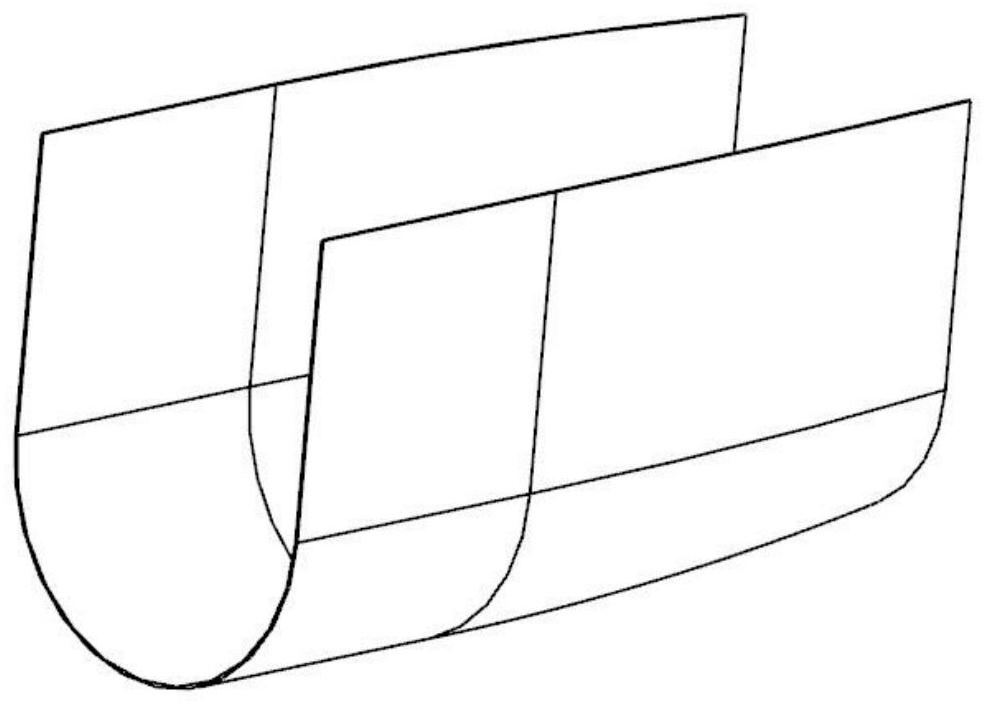

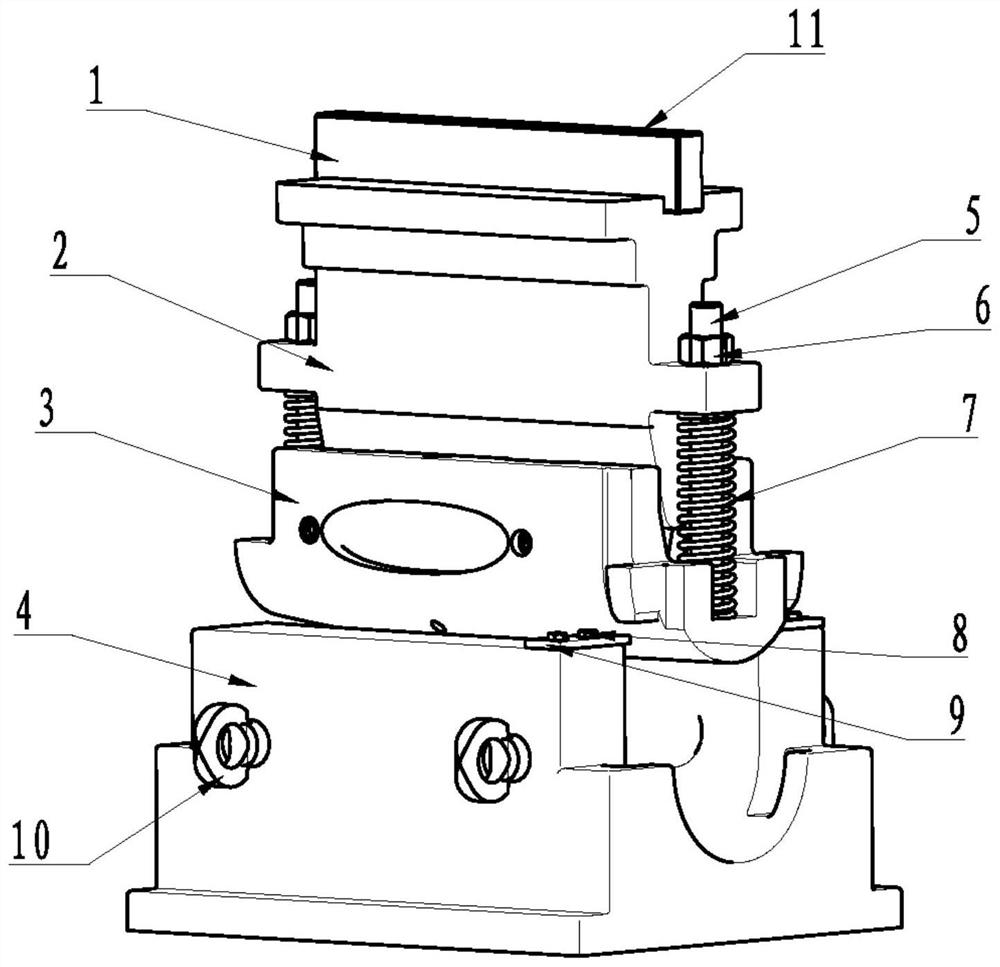

Double-lateral extension forming device and forming method for irregular curved surface part

ActiveCN112692148AShorten the production cycleSimple processShaping toolsMetal-working feeding devicesElastic componentMetal machining

The invention relates to a double-lateral extension forming device and forming method for an irregular curved surface part, belongs to the technical field of sheet metal machining, and solves the problems that in the prior art, an irregular complex-surface thin-wall component cannot be formed at a time, the requirement for welding is high, the machining cost of the part is high, the production period is long, and die releasing is difficult. The extension forming device comprises an upper die, a lower die and a pressing forming assembly, wherein the upper die extends and forms a to-be-formed process workpiece in a lower die cavity through the pressing forming assembly; the pressing forming assembly comprises a molded surface pressing block, a protrusion pressing male die and a plurality of first elastic components, wherein the protrusion pressing male die is assembled in a through hole of the molded surface pressing block and is fixed to the molded surface pressing block, the outer molded surface of the protrusion pressing male die is matched with the molded surface of the through hole of the molded surface pressing block, one end of each first elastic component is fixed to the molded surface pressing block, and the other end of each first elastic component is fixed to the protrusion pressing male die. By means of the device and method, double-lateral extension forming of the irregular curved surface part is achieved at one time.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

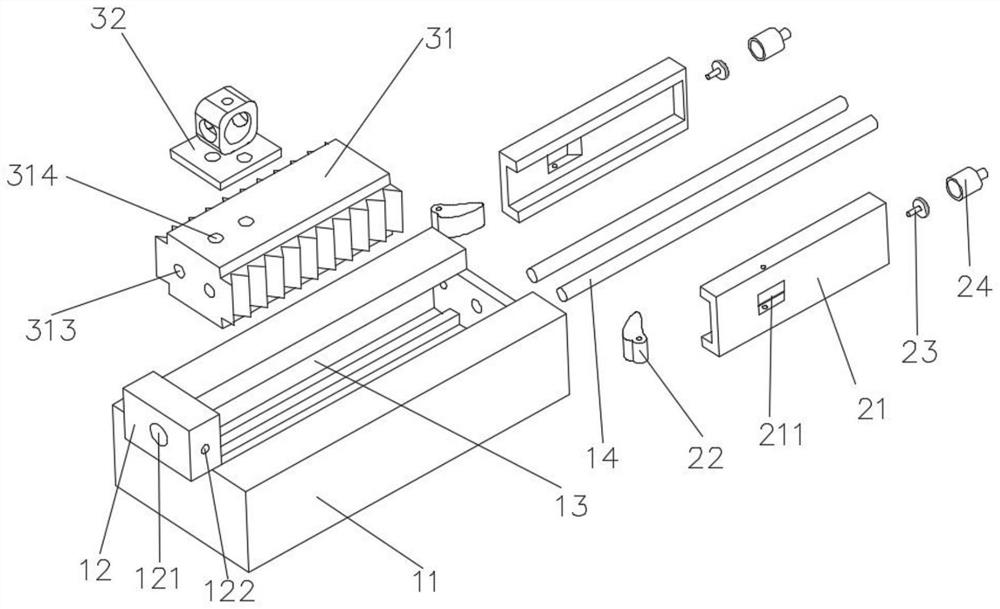

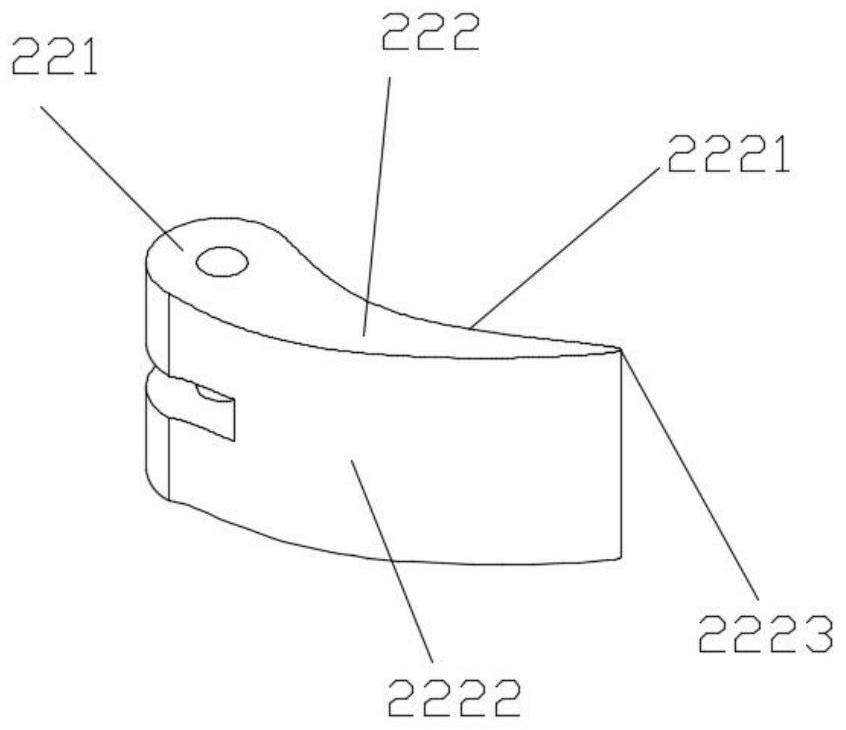

Optical fiber conduit one-way stepping device and driving system

PendingCN114110114AAvoids problems with back and forth movement contaminating tissueImprove securityGearingCatheterRatchetEngineering

The invention relates to an optical fiber catheter one-way stepping device and a driving system, belongs to the field of ablation operation devices, and solves the problems that a stepping device in the prior art is inaccurate and unstable in displacement and cannot be used in a nuclear magnetic environment. An optical fiber conduit one-way stepping device comprises a driving assembly and a stepping assembly, and the driving assembly is used for driving the stepping assembly to move; the stepping assembly comprises a machine base, a driving stepping part and a driven stepping part, the driving stepping part and the driven stepping part are arranged in the machine base and are mutually meshed and connected in a ratchet wheel and ratchet mode, and the driving assembly drives the driving stepping part to drive the driven stepping part to conduct one-way stepping. The driven stepping part drives the optical fiber conduit to realize synchronous one-way stepping motion; the precision and the stability are improved by driving the optical fiber conduit to move unidirectionally and equidistantly.

Owner:HANGZHOU GENLIGHT MEDTECH CO LTD

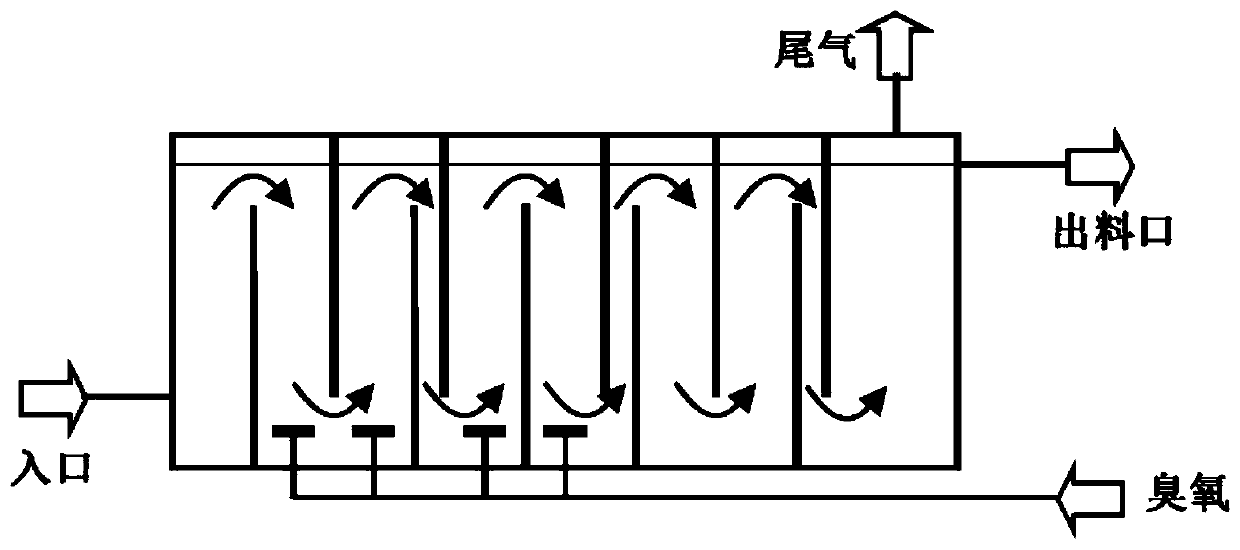

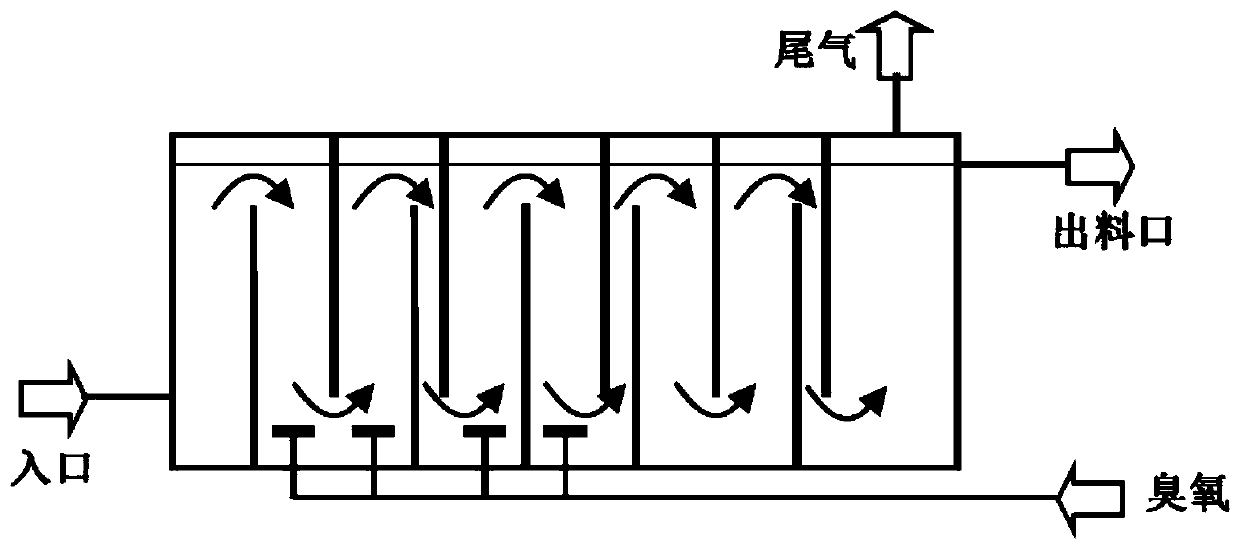

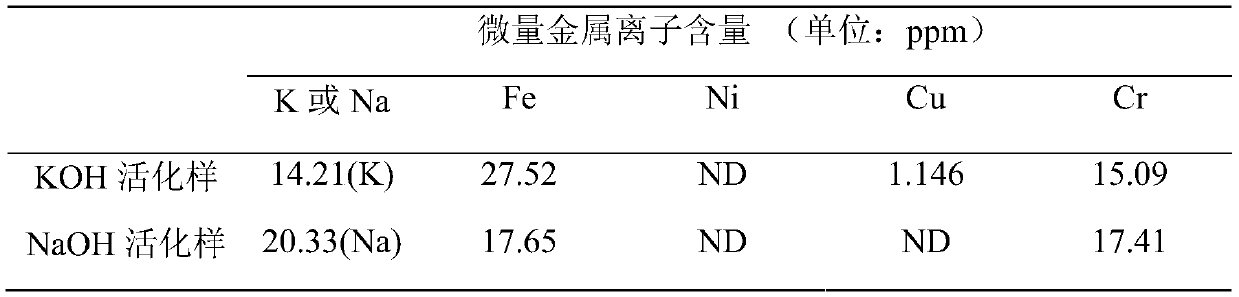

Method for removing metal ions in electrode material and supercapacitor

ActiveCN111128566AEliminate static electricityNot too little solidCarbon compoundsHybrid capacitor electrodesCapacitanceSurface oxidation

The invention relates to a method for removing metal ions in an electrode material and a supercapacitor. The invention belongs to the technical field of new energy materials, and solves the problem that the existing process of removing metal ions requires repeated treatment of the material, which generates a large amount of acid-containing wastewater and which causes great environmental protectiontreatment pressure, and the problem of the technical requirement that the concentration sum of the metal ions in a super-capacitor electrode carbon material is smaller than 200 ppm cannot be met dueto the fact that the concentration sum of the metal ions in the electrode material treated through the existing technology is too high. The method for removing the metal ions in the electrode materialcomprises the following steps: 1, preparing water carbon slurry; 2, carrying out surface oxidation treatment on the raw material carbon in the water carbon slurry by adopting an ozone contact oxidation method; and 3, carrying out heating treatment on the water-carbon slurry subjected to ozone contact treatment. By means of ozone contact oxidation and heating treatment, the sum of the content of various metal ions is removed to the level smaller than 60 ppm.

Owner:INST OF CHEM CHINESE ACAD OF SCI

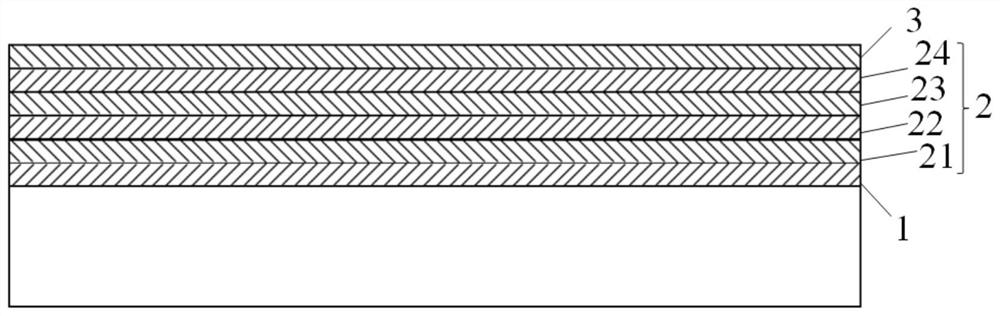

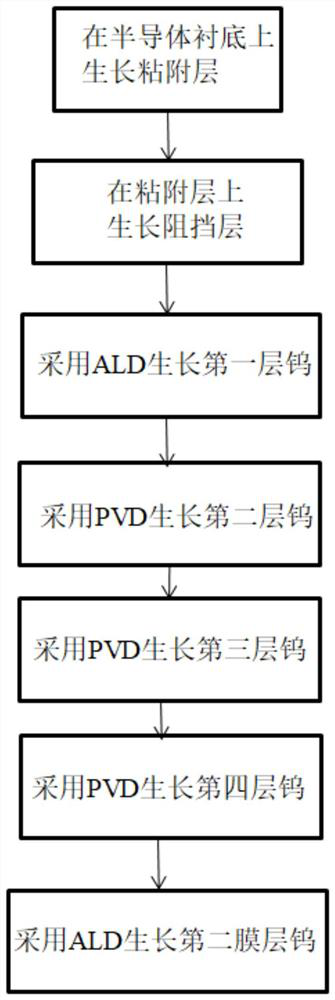

Tungsten composite film layer and growth method thereof, and monolithic 3DIC

ActiveCN113053804AGood filling effectConducive to interconnectionSemiconductor/solid-state device manufacturingComposite materialMonocrystalline silicon

The invention relates to a tungsten composite film layer and a growth method thereof, and a monolithic 3DIC, belongs to the technical field of semiconductor manufacturing, and solves the problem of wrinkling of a monocrystalline silicon layer caused by a large stress of tungsten grown by an existing method. The tungsten composite film layer is located on a semiconductor substrate and comprises a first film layer close to the side of the semiconductor substrate and a second film layer away from the side of the semiconductor substrate; the stress directions of the first film layer and the second film layer are opposite; the stress of the first film layer is a compressive stress, and the stress of the second film layer is a tensile stress; and the first film layer includes a plurality of film layers. The growth method of the tungsten composite film layer comprises the following steps: growing the first film layer on the semiconductor substrate; and growing the second film layer with the stress direction opposite to that of the first film layer on the first film layer. According to the invention, the low stress of the tungsten composite film layer is realized.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Coaxiality and symmetry degree detection device and detection method

ActiveCN112484611ASimple structureRealize detectionMechanical measuring arrangementsPhysicsHollow cylinder

The invention relates to a coaxiality and symmetry degree detection device and detection method, belongs to the technical field of coaxiality and symmetry degree detection, and solves the problem thatno device for detecting the coaxiality and symmetry degree of a folding rudder stepped hole exists in the prior art. The coaxiality and symmetry degree detection device comprises a positioning frameand a positioning shaft, wherein the positioning frame is a cylinder and comprises a matching section and a first detection section, and the first detection section is inserted into a first hole of the coaxiality to be detected; and the positioning shaft is a hollow cylinder and comprises a second detection section and an internal cavity corresponding to the second detection section, the second detection section is inserted into a second hole with the coaxiality to be detected, and the matching section is inserted into the internal cavity. According to the coaxiality and symmetry degree detection device and the detection method, high-precision detection of the coaxiality and the symmetry degree of the folding rudder stepped hole is realized.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Forming die and forming method for special-shaped curved surface structural parts

ActiveCN112475052BRealize one-time formingReduce performanceShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention relates to a forming mold and a forming method for a special-shaped curved surface structural part, which belongs to precision sheet metal processing, and solves the problems in the prior art that it is impossible to form products with non-uniform wall thickness special-shaped curved surfaces at one time, the surface quality of the product is poor, and the processing efficiency is low. . The forming mold includes an upper mold and a lower mold; the upper surface of the lower mold is provided with an opening, and the blank is in contact with the lower surface of the upper mold, and enters the cavity of the lower mold through the opening; the side of the upper mold is provided with steps, and the steps are connected with blanks of different thicknesses. Corresponding to the non-flat surface of . The forming method includes making a blank; welding the blank; placing the welded blank on a forming mold, and the welding seam corresponds to the steps of the upper mold; lowering the upper mold and the jacking cylinder to complete the one-time forming of the non-uniform wall thickness special-shaped curved surface structure. The invention realizes the one-time forming of the non-uniform wall-thickness special-shaped curved surface structural parts.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Preparation method of carbon sol for electrode material, capacitive energy storage device and application

ActiveCN111115628ALarge capacityMeet the growing demand for capacityCarbon compoundsHybrid capacitor electrodesComposite materialCapacitive energy storage

The invention relates to a preparation method of carbon sol for an electrode material, a capacitive energy storage device and application, belongs to the technical field of energy storage device materials, and solves the problem of poor comprehensive performance of a carbon material due to the fact that an existing preparation method cannot balance relatively high conductivity, high specific surface area, controllable pore structure, relatively high stability, processability, composite compatibility, relatively high purity and relatively low cost. The preparation method of the carbon sol for the electrode material comprises the following steps: adding a catalyst into dispersion medium diphenyl ether / polyethylene glycol 400, and heating; adding a thermosetting resin reaction solution into the dispersion medium, carrying out suspension polymerization reaction to generate a carbon sol precursor material, and separating to obtain the carbon sol precursor material; and carrying out activation processing on the carbon sol precursor material to obtain the carbon sol. By changing the existence form of the carbon material for the electrode material, the specific surface area is greatly increased, and the capacity of the capacitive energy storage device is increased.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Phenol-cyanogen wastewater reduction method

ActiveCN112939358AReduce delivery volumeAchieve reductionWater treatment parameter controlSpecific water treatment objectivesWater usePhenol

The invention relates to a phenol-cyanogen wastewater decrement method, belongs to the technical field of phenol-cyanogen wastewater, and solves the problems that no related technology for reducing wastewater generation from a phenol-cyanogen wastewater source exists at present, and the wastewater generated in each link of a coking process has many types of pollutants after being mixed, and the treatment difficulty and the treatment capacity are large. The phenol-cyanogen wastewater decrement method comprises ammonium sulfate acid gas condensate decrement treatment, coal gas condensate decrement treatment, defoaming water decrement treatment of a phenol-cyanogen wastewater treatment station and accident water pool decrement treatment. According to the invention, the output of phenol-cyanogen wastewater is reduced from the source.

Owner:内蒙古包钢集团环境工程研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com