A polyimide adhesive film with excellent comprehensive properties and its preparation method and application

A technology of polyimide adhesive film and comprehensive performance, applied in the field of polyimide, can solve the problems of low dielectric constant, low dielectric loss, etc. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

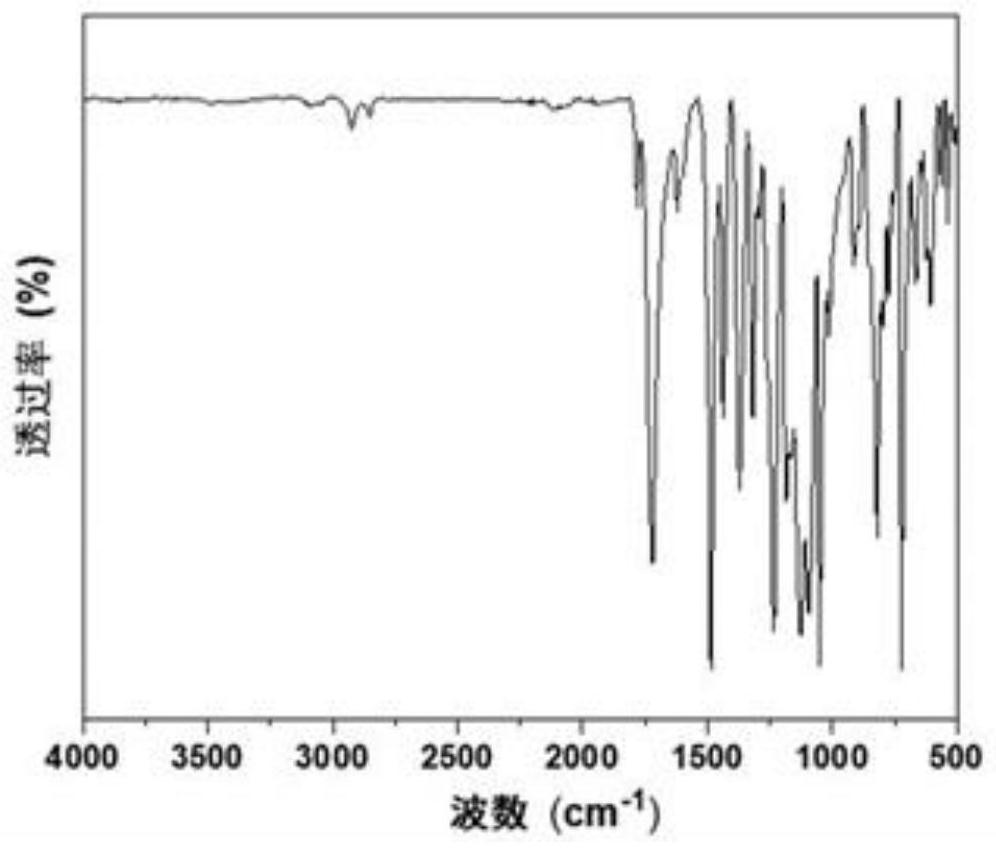

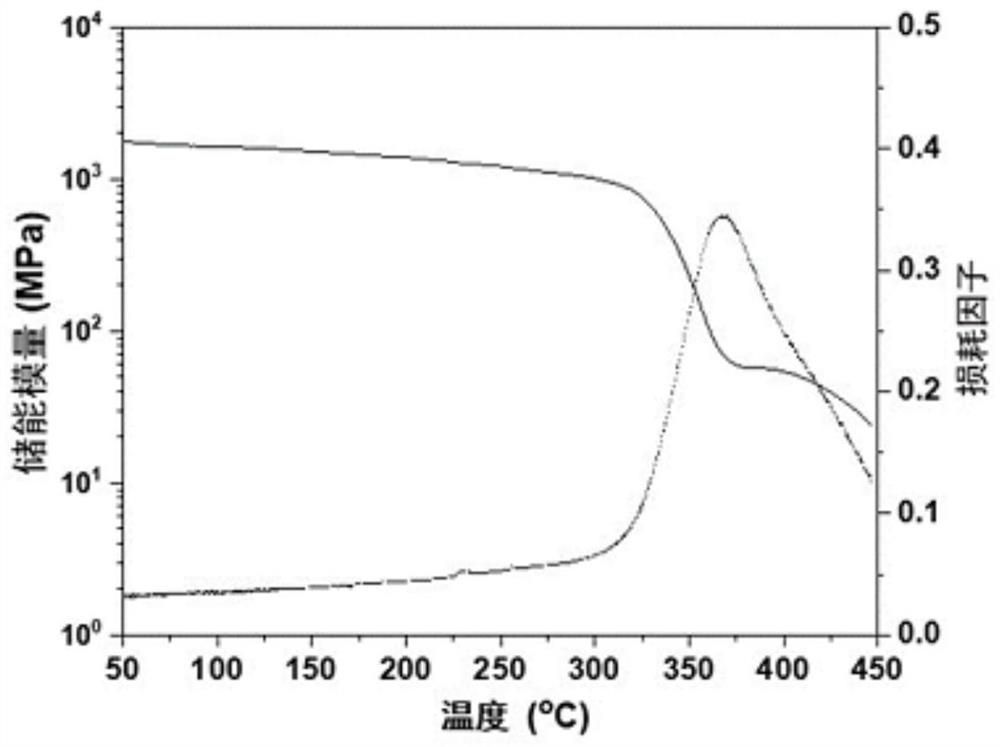

Embodiment 1

[0052] In a three-necked flask equipped with mechanical stirring, water separator, nitrogen conduit and thermometer, add 38.54 g (0.09 mol) of 1,4-bis(2-trifluoromethyl-4-aminophenoxy)benzene (6FAPB) , 8.00 g (0.01 mol) of bis(3-aminopropyl) polydimethylsiloxane (PDMS) and 200 g of N,N-dimethylacetamide (DMAc), stirred at room temperature under nitrogen protection until completely dissolved A homogeneous solution was obtained. After cooling the above reaction system to 5°C, add 21.81 g (0.1 mol) 1,2,4,5-pyromellitic anhydride (PMDA) and 187 g DMAc, stir for 3 hours until completely dissolved, and continue stirring at room temperature After 14 hours of reaction, a polyamic acid solution with a solid content of 15 wt.% was obtained. After filtration and vacuum defoaming, the obtained polyamic acid solution was coated on a polytetrafluoroethylene plate with a smooth surface, and most of the solvent was removed by thermal drying at 60°C for 1.5 hours, and then peeled off from the...

Embodiment 2

[0054] In a three-necked flask equipped with mechanical stirring, water separator, nitrogen conduit and thermometer, add 50.81 g (0.098 mol) of 2,2-bis[4-(4-aminophenoxybenzene)]hexafluoropropane (HFBAPP) , 0.49 g (0.002 mol) of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane (SiDA) and N,N-dimethylacetamide (DMAc ) 249 g, stirred at room temperature under nitrogen protection until completely dissolved to obtain a homogeneous solution. After cooling the above reaction system to 0°C, add 21.81 g (0.1 mol) 1,2,4,5-pyromellitic anhydride (PMDA) and 200 g DMAc, stir for 2 hours until completely dissolved, and continue stirring at room temperature After 11 hours of reaction, a polyamic acid solution with a solid content of 14 wt.% was obtained. After filtering and vacuum defoaming, the obtained polyamic acid solution was coated on a glass plate with a smooth surface, and most of the solvent was removed by heating at 80°C / 1 hour, and then peeled off from the glass plate, and t...

Embodiment 3

[0056] In a three-necked flask equipped with mechanical stirring, water separator, nitrogen conduit and thermometer, add 49.25 g (0.095 mol) of 2,2-bis[4-(4-aminophenoxybenzene)]hexafluoropropane (HFBAPP) , 1.24 g (0.005 mol) of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane (SiDA) and N,N-dimethylacetamide (DMAc ) 250 g, stirred at room temperature under nitrogen protection until completely dissolved to obtain a homogeneous solution. After cooling the above reaction system to 5°C, add 21.81 g (0.1 mol) 1,2,4,5-pyromellitic anhydride (PMDA) and 129 g DMAc, stir for 2 hours until completely dissolved, and continue stirring at room temperature After 10 hours of reaction, a polyamic acid solution with a solid content of 16 wt.% was obtained. After filtering and vacuum defoaming, the obtained polyamic acid solution was coated on a glass plate with a smooth surface, and most of the solvent was removed by thermal drying at 70°C for 1.5 hours, and then peeled off from the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com