Manufacturing method of capacitive coupling type slip ring

A production method and capacitive coupling technology, applied in the manufacture of slip rings, etc., can solve the problems of high cost and increased equipment volume, and achieve the effects of improving utilization, increasing equipment volume, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

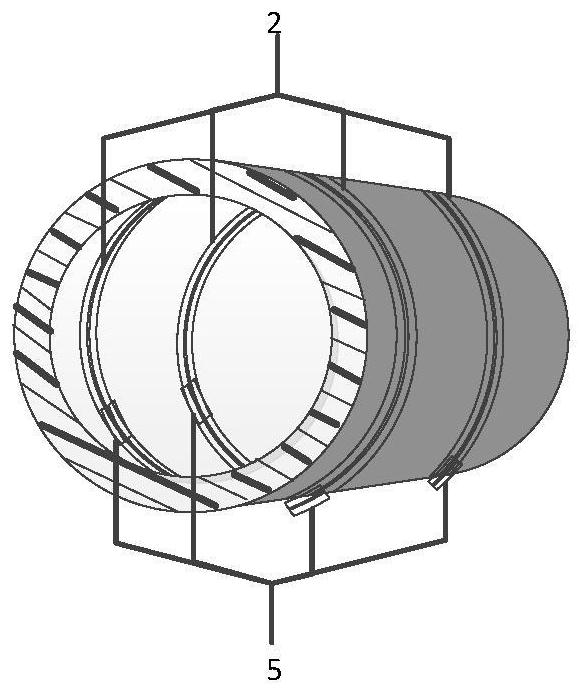

[0043] A specific embodiment of the present invention discloses a capacitively coupled slip ring, which includes a rotating disc 1, a sending unit and a receiving unit.

[0044] Such as figure 1 As shown, the sending unit includes a sending antenna 2 and a data processing unit at the sending end, the data processing unit at the sending end includes a sending circuit board and a data line, and both the sending antenna 2 and the data line are connected to the sending circuit board. Exemplarily, the sending antenna 2 is connected to the sending circuit board in the form of a connector. The sending circuit board is fixed on the rotating disk.

[0045] The shape of the transmitting antenna adopted in the present invention is flat, or strip-shaped.

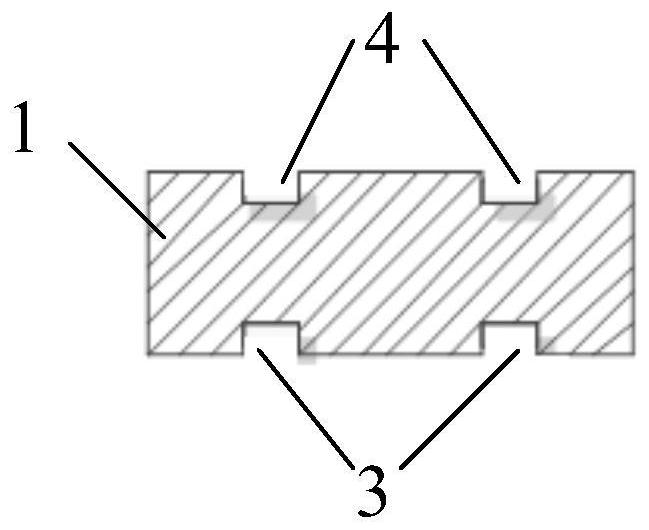

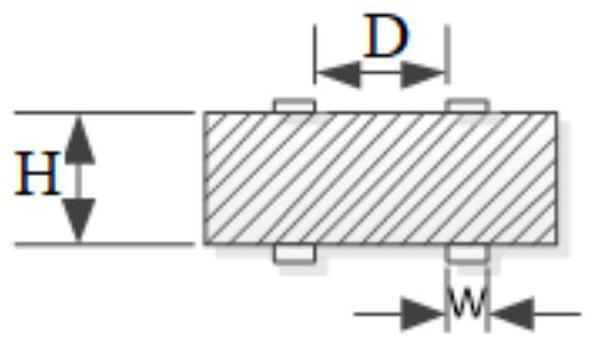

[0046] The rotating disk is hollow inside and has a large aperture ring shape, and its outer surface is provided with a first groove 3 arranged circumferentially. The shape of the first groove 3 matches the shape of the transmitting a...

Embodiment 2

[0059] Another specific embodiment of the present invention discloses a CT detection device. The capacitively coupled slip ring is one of the key components of the CT, and is used for power and data transmission between the CT rotor end and the stator end.

[0060] With the advancement of CT technology, the amount of data collected by detectors is increasing day by day. The required data transmission bandwidth can be estimated by Equation 6, and the following relationship between the number of CT layers and data bandwidth can be obtained. Formula 6:

[0061]

[0062] Among them, S is the data transmission bandwidth; P is the number of multi-layer spiral CT DAS channels; n is the number of single-layer spiral CT detectors; m is the number of single-sampling data bits for each detector; v is the rotation speed of the slip ring; f is the sampling frequency.

[0063] The corresponding relationship between the number of CT layers and the data bandwidth is as follows: Figure 9...

Embodiment 3

[0068] Existing transmitting antennas are usually capacitively coupled antennas, which are usually made of printed circuit boards (PCB). The PCB board is based on an insulating board, cut to a certain size, with at least one conductive pattern on it, and holes (such as component holes, fastening holes, metallized holes, etc.), used to replace the electronic components of the previous installation Chassis, and realize the interconnection between electronic components. Because they are made using electronic printing, they are called "printed" circuit boards. The current PCB board is mainly composed of lines and graphics, dielectric layers, holes, solder resist ink, silk screen and surface treatment.

[0069] The advantages of capacitive coupling antennas made of PCB boards are: due to the repeatability (reproducibility) and consistency of PCB board graphics, wiring and assembly errors are greatly reduced, and antenna maintenance, debugging and inspection time are saved. Standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com