Thermosetting polyimide resin, prepolymer, preparation method and application thereof

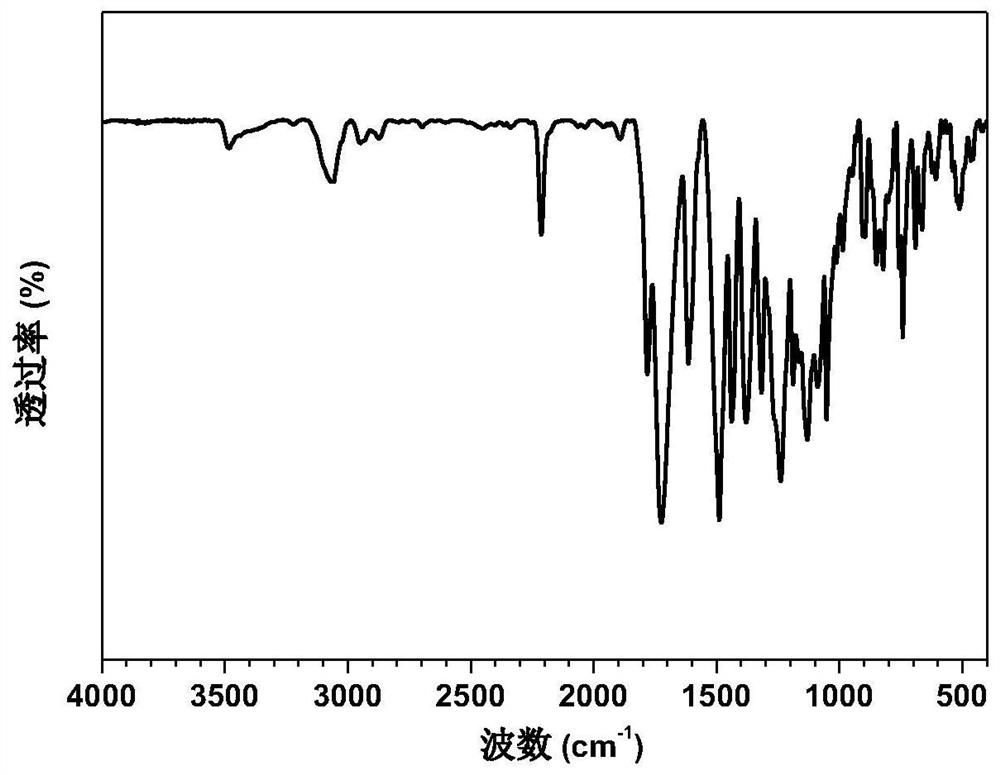

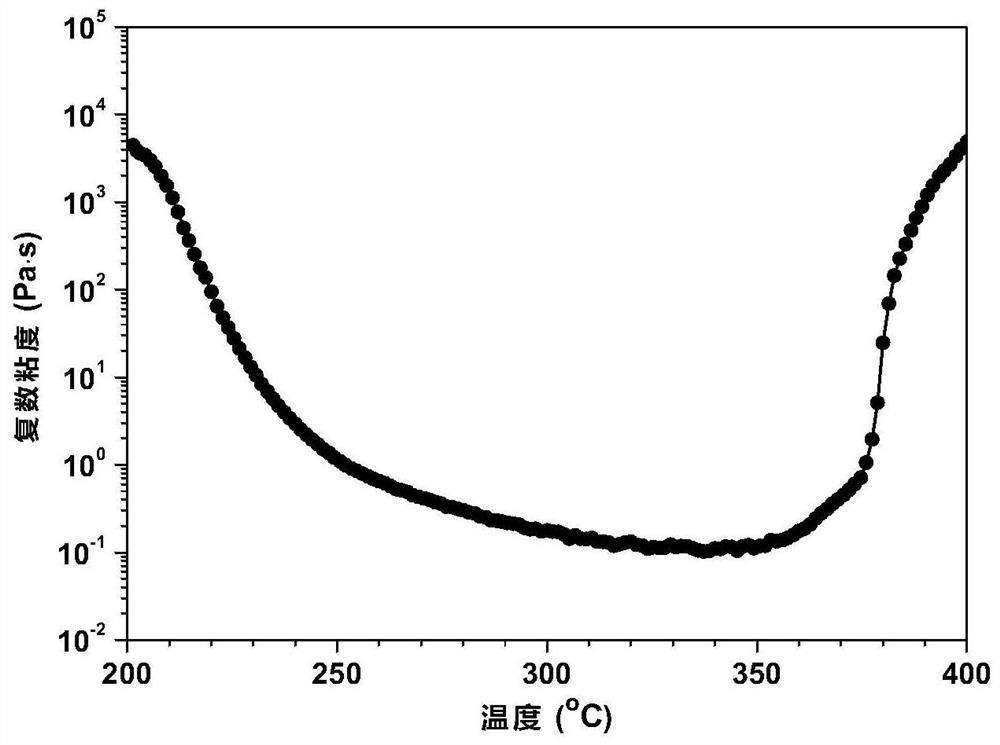

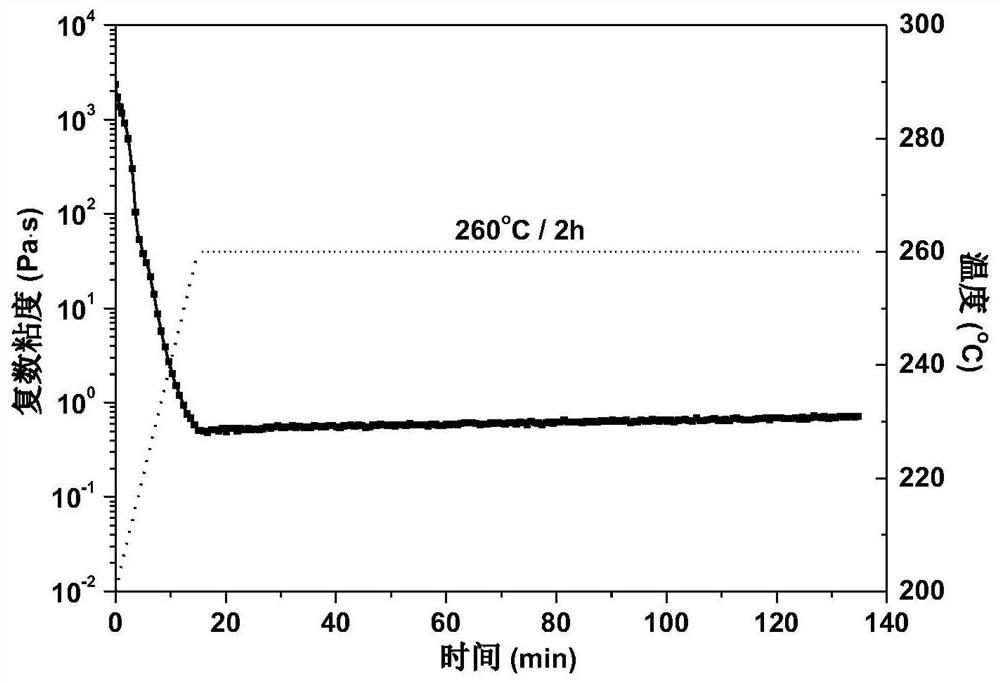

A technology of polyimide resin and prepolymer, applied in the field of preparation, thermosetting polyimide resin and prepolymer containing siloxane structure, which can solve the problem of low glass transition temperature of resin and achieve good melt flow properties, high heat resistance, and high melt stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Add 14.41g (45.0mmol) of 4,4'-diamino-2,2'-bistrifluoromethyl to a three-necked round-bottomed flask equipped with a mechanical stirring paddle, a water separator, a condenser, a nitrogen inlet and outlet, and a thermometer Biphenyl (TFDB), 3.70g (15.0mmol) of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane (SIDA) and 70.8g of N- Methylpyrrolidone (NMP), stirred under the protection of nitrogen until completely dissolved to obtain a homogeneous solution, and then 8.38g (26.0mmol) of 2,3,3',4'-benzophenone tetraacid dianhydride (α- BTDA) and 16.88g (68.0mmol) of 4-phenylethynylphthalic anhydride (PEPA) mixed with 30.4g of N-methylpyrrolidone (NMP) were added to the above-mentioned homogeneous solution, and continued to stir at room temperature for 12 After one hour, a polyamic acid resin solution with a solid content of 30 wt.% was obtained. Add 10.1g of toluene to the above polyamic acid resin solution, heat the reaction system to 180°C and reflux for 10 hours, th...

Embodiment 2

[0066] Add 7.64g (36.0mmol) of 4,4'-diaminobenzophenone (DABP), 5.92g ( 24.0mmol) of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane (SIDA) and 70.8g of N,N-dimethylacetamide (DMAc ), stirred under nitrogen protection until completely dissolved to obtain a homogeneous solution, then 11.60g (36.0mmol) of 2,3,3',4'-benzophenonetetraacid dianhydride (α-BTDA) and 11.92g (48.0mmol) of 4-phenylethynylphthalic anhydride (PEPA) and 41.7g of N,N-dimethylacetamide (DMAc) mixed slurry was added to the above-mentioned homogeneous solution, and continued to stir and react at room temperature for 12 hours Finally, a polyamic acid resin solution with a solid content of 40 wt.% was obtained. Add 8.4g of toluene to the above polyamic acid resin solution, raise the temperature of the reaction system to 148°C for reflux reaction for 14 hours, distill the toluene off, stop heating, cool the reaction solution to 80-120°C, pour deionized water and A crude resin product was obtained from a mi...

Embodiment 3

[0069] Add 17.29 g (54 mmol) of 4,4'-diamino-2,2'-bistrifluoromethylbisin into a three-necked round-bottomed flask equipped with a mechanical stirring paddle, a water separator, a condenser, a nitrogen inlet and outlet, and a thermometer. Benzene (TFDB), 1.65g (6mmol) of bis(4-aminophenoxy)dimethylsilane (APDS) and 84.3g of N-methylpyrrolidone (NMP), stirred under nitrogen protection until completely dissolved to obtain a homogeneous phase solution, and then 9.31g (30.0mmol) of 2,3,3',4'-diphenyl ether tetra-acid dianhydride (α-ODPA) and 14.89g (60.0mmol) of 4-phenylethynylphthalic anhydride (PEPA ) and 21.1 g of N-methylpyrrolidone (NMP) mixed slurry was added to the above-mentioned homogeneous solution, continued to stir and react at room temperature for 12 hours to obtain a polyamic acid resin solution with a solid content of 30wt.%. Add 10.1g of toluene to the above polyamic acid resin solution, heat up the reaction system to 178°C and reflux for 12 hours, then distill out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com