Method for removing metal ions in electrode material and supercapacitor

A technology of supercapacitors and metal ions, applied in the direction of hybrid capacitor electrodes, non-metallic elements, chemical instruments and methods, etc., can solve problems such as uneven particle size distribution, short device life, and environmental protection treatment pressure, and achieve low process efficiency. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

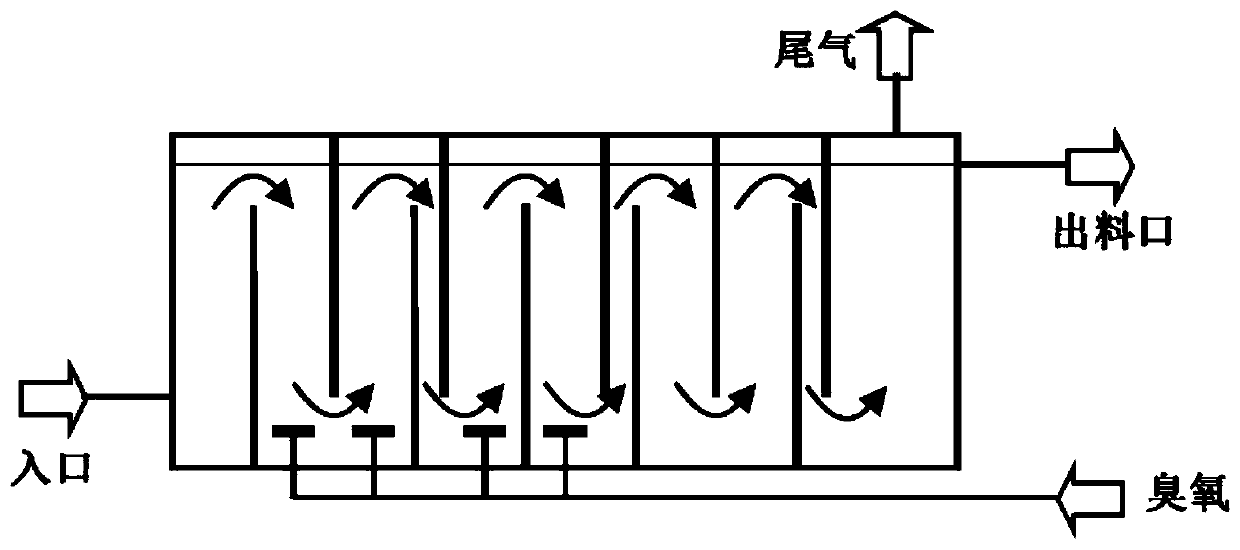

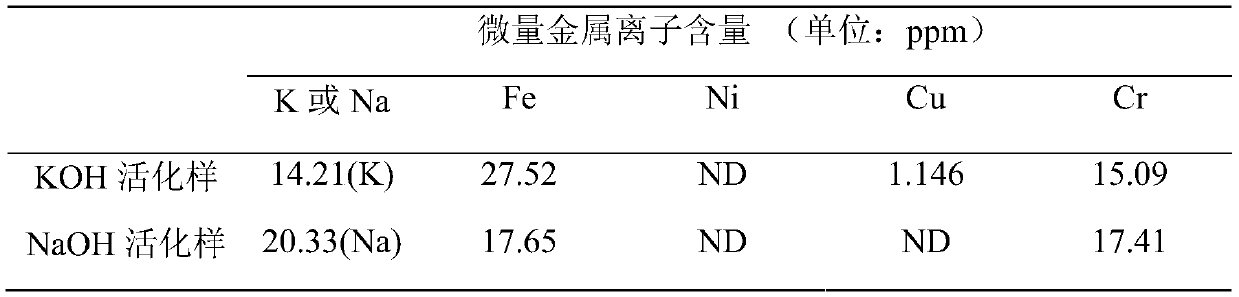

[0068] Wood activated carbon activated by potassium hydroxide or sodium hydroxide was neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water carbon slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 650° C. for 120 minutes under a nitrogen atmosphere. The content of various metal ions ...

Embodiment 2

[0073] Coconut shell activated carbon activated by potassium hydroxide or sodium hydroxide is neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water-charcoal slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 750° C. for 60 minutes under a nitrogen atmosphere. The content of various me...

Embodiment 3

[0078] The coal-based activated carbon activated by potassium hydroxide or sodium hydroxide is neutralized with dilute nitric acid (concentration) to a surface pH value of 7.0, and then prepared with deionized water to form a water-carbon slurry with a solid content of 20 wt%. The ratio of the amount of ozone used in the ozonation process to the volume of the water-charcoal slurry was 1.2 mg / L, and the contact time between the ozone / air flow and the water-charcoal slurry was 20 minutes. The temperature range of the heat treatment of the oxidized water-carbon slurry is 85°C, and the treatment time is 45 minutes. Press filtration removes most of the water without further drying, and the wet sample is directly reconstituted with deionized water to make a water-charcoal slurry. Repeat the ozonation and heat treatment once. The treated carbon material was press-filtered, dried, and then heat-treated at 850° C. for 30 minutes under a nitrogen atmosphere. The content of various met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com