Preparation method of carbon sol for electrode material, capacitive energy storage device and application

An electrode material and capacitive energy storage technology, applied in chemical instruments and methods, hybrid capacitor electrodes, carbon compounds, etc., can solve the problem of poor comprehensive performance of carbon materials, high conductivity specific surface area, controllable pore structure stability, and easy processing Issues such as compatibility and composite compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

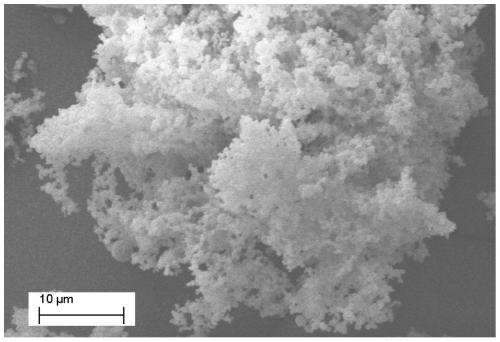

[0036] A specific embodiment of the present invention discloses a method for preparing an ultra-high specific surface carbon sol, comprising the following steps:

[0037] Step 1: Take diphenyl ether / polyethylene glycol 400 as the dispersion medium, add a catalyst to the dispersion medium, and raise the temperature to 60-170°C under high-speed stirring, preferably 90-150°C;

[0038] Step 2: adding a thermosetting resin reaction solution to the dispersion medium, and polymerizing to form a carbon sol precursor material;

[0039] Step 3: The generated carbon sol precursor material is separated from the dispersion medium, the solid is washed three times with petroleum ether (boiling point 60-90° C.), and dried in a nitrogen stream.

[0040] Step 4: Carrying out primary carbonization of the carbon sol precursor material obtained in step 3 at a temperature of 600-900°C, preferably 650-900°C;

[0041] Step 5: mixing the primary carbonized carbon sol precursor material with potassium...

Embodiment 1

[0061] The preparation process of phenolic resin prepolymer (Resols resin) is according to literature (D.Broun, H.Cherdron, M.Rehahn, H.Ritter, B.Viot, Polymer Synthesis: Theory and Practice, Fourth Edition, Springer, 2005, pp. 299) method implementation. The above prepolymerized phenolic resin is used to configure the reaction solution, and the suspension polymerization process is carried out according to the condition data listed in Table 1.

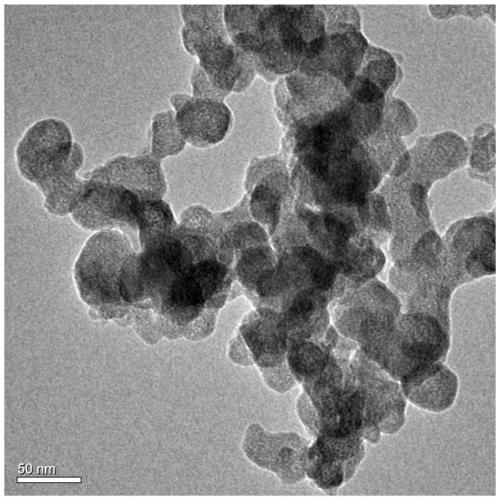

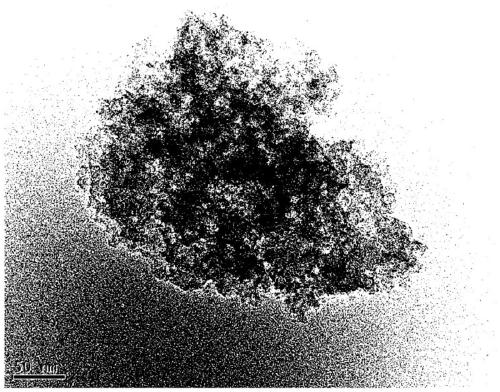

[0062] The precursor material prepared above is subjected to primary carbonization treatment, the primary carbonization treatment is carried out in a corundum tube, and the treated samples are placed in a corundum crucible. The temperature of the treatment was 600°C. The entire primary carbonization process is carried out under a nitrogen protective atmosphere, and the nitrogen flow rate is 60 ml / min. The primary carbonization treatment time was 3.0 hours. The treated material was cooled to room temperature in a nitrogen stream. Th...

Embodiment 2

[0071] The reaction solution was prepared from furan methanol, and the suspension polymerization process was implemented according to the condition data listed in Table 3.

[0072] The precursor material prepared above is subjected to primary carbonization treatment, the primary carbonization treatment is carried out in a corundum tube, and the treated samples are placed in a corundum crucible. The temperature of the treatment was 700°C. The entire primary carbonization process is carried out under a nitrogen protective atmosphere, and the nitrogen flow rate is 300 ml / min. The primary carbonization treatment time was 2.0 hours. The treated material was cooled to room temperature in a nitrogen stream. The primary carbonized material is activated in a high temperature resistant stainless steel tube, and the mixed sample of carbon powder and potassium hydroxide is placed in a nickel box. Wherein the mass ratio of potassium hydroxide to carbon powder is 4.5:1. The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com