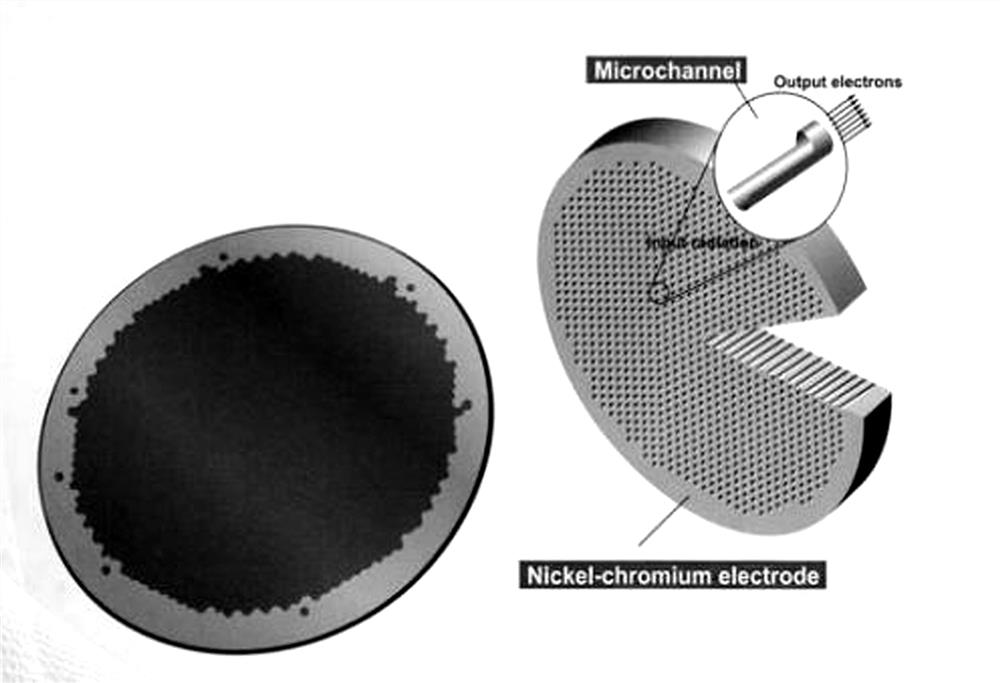

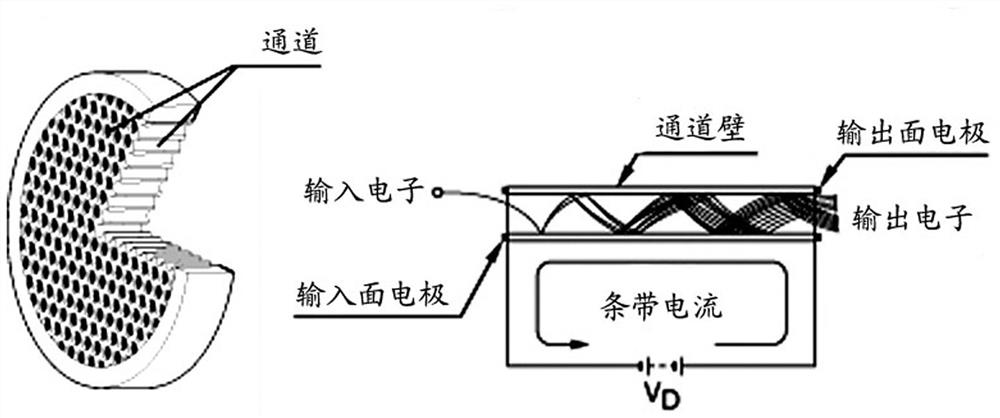

In-channel polishing method of microchannel plate

A micro-channel plate, internal polishing technology, applied in electrode system manufacturing, discharge tube/lamp manufacturing, electron multiplier details, etc., can solve the problem of large channel wall roughness, achieve high gain, low noise, cumulative Pick up effects with high charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

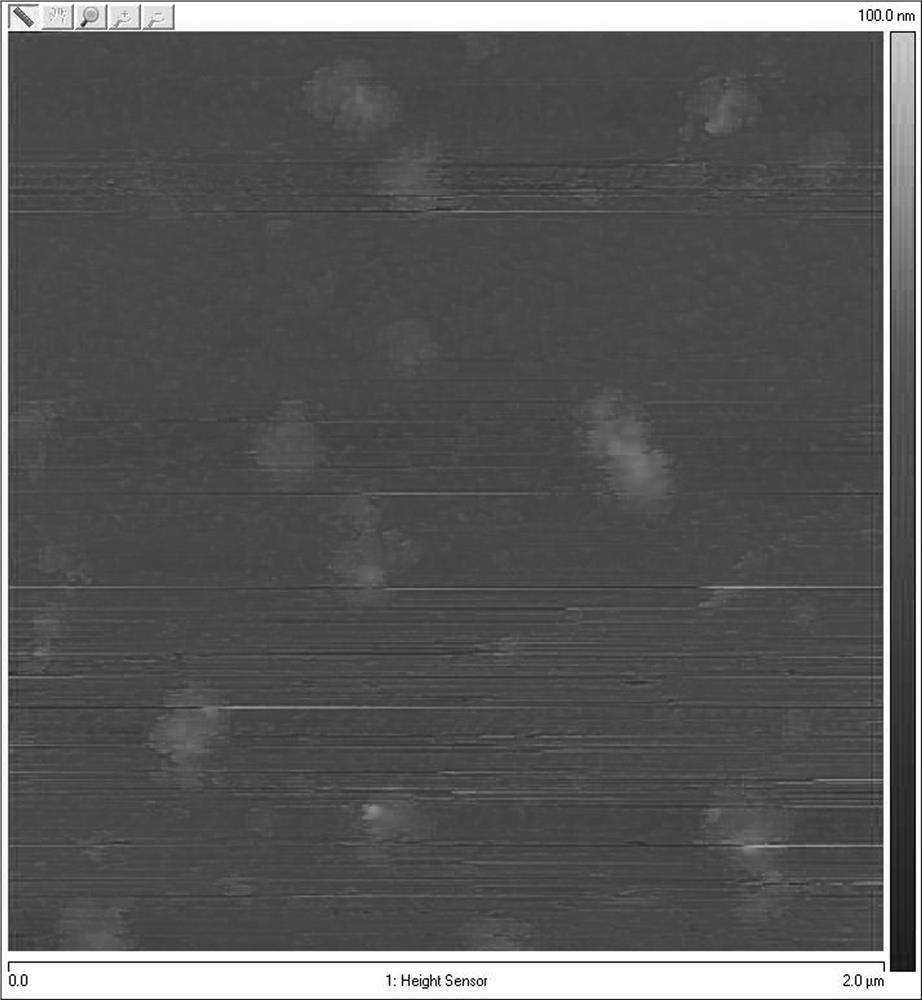

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific examples.

[0028] A polishing method in the channel of a microchannel plate: the following steps are carried out by using the fabricated microhole array glass blank:

[0029] ① Place the microporous array glass blank in the mixed solution of nitric acid and hydrofluoric acid, and vibrate in the ultrasonic wave for 10-20 minutes;

[0030] ②Replace with a new mixture of nitric acid and hydrofluoric acid, and stir in a magnetic stirrer for 20 to 40 minutes;

[0031] ③Take out the micropore array glass blank from the nitric acid hydrofluoric acid mixture, and then place the micropore array glass blank in pure water for cleaning and changing the water for 8 to 15 times;

[0032] ④ After cleaning, place the microporous array glass blank in a mixture of hydrofluoric acid and sulfuric acid, and stir in a magnetic stirrer for 20 to 40 minutes;

[0033] ⑤ Take out the microporous array glass blank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com