Probiotic preparation and preparation method thereof

A probiotic preparation and probiotic technology, applied in the field of probiotic preparation and its preparation, can solve the problems of short probiotic activity retention time and single effect of probiotic preparation, achieve high-quality and high-efficiency processing and preparation, and the overall quality is stable and reliable High degree, the effect of regulating the balance of intestinal flora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0051] Preparation of probiotic preparations

[0052] According to the raw materials and raw material ratios of the probiotic preparations in Table 1, the probiotic preparation products of Examples 1-10 were prepared.

[0053] Table 1 is the raw material and raw material proportioning situation of embodiment 1-10 probiotic preparation

[0054]

[0055] The preparation steps are as follows:

[0056] Step a, mixing inulin and xylo-oligosaccharide in proportion and stirring to obtain the first mixed material.

[0057] Step b, mixing the first mixed material obtained in step a with Bifidobacterium lactis HN019 and Bifidobacterium lactis V9 in an equal increasing manner, and then mixing in a three-dimensional mixer for 40 minutes at a speed of 30 r / min to obtain a second mixture material.

[0058] Step c. Subpackage the second mixed material prepared in step b with a powder packaging machine to obtain a powder probiotic preparation in bags. Wherein, the ambient temperature o...

Embodiment 11

[0065] Preparation of probiotic preparations

[0066] Take the following raw materials according to the weight ratio: 62.46 parts of dietary fiber (35.67 parts of inulin; 22.38 parts of xylo-oligosaccharides; 2.97 parts of polydextrose; 1.44 parts of red bracken fiber powder); 7.9 parts of probiotics (Bifidobacterium lactis V9 is 3.3 parts; Bifidobacterium lactis HN019 is 4.6 parts;); cheese 0.27 parts; sugar alcohol 6.48 parts; cranberry powder 1.65 parts.

[0067] Mix the dietary fiber, sugar alcohol, cheese, and cranberry powder thoroughly, and then mix the probiotics and other materials in equal increments. Then mix the mixed material in a three-dimensional mixer at a speed of 20r / min for 35min, and then pack the resulting mixed material with a powder packaging machine, and pack it into a product of 3g per bag. 10 CFU / bag. It is required that the production and processing temperature be controlled at about 22±2°C, and the humidity be controlled at about 30+5%.

[0068] ...

Embodiment 12

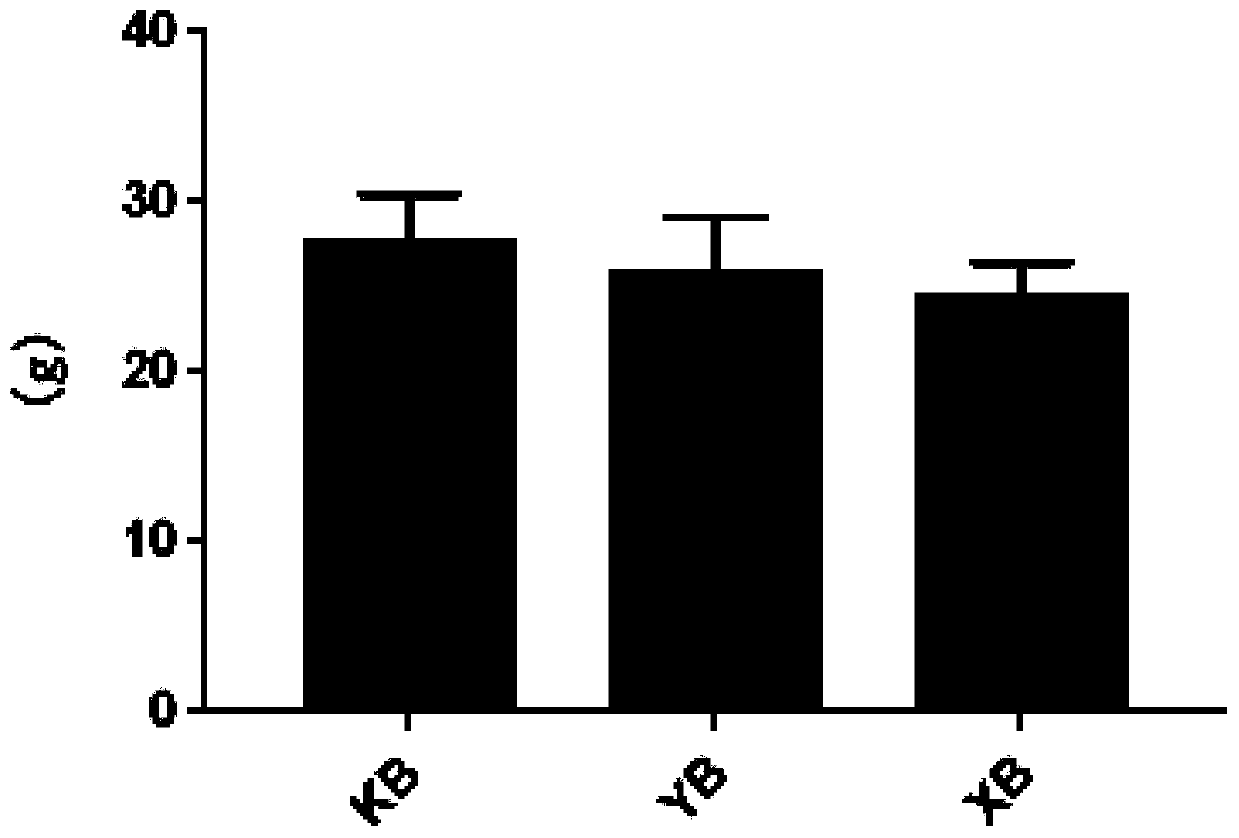

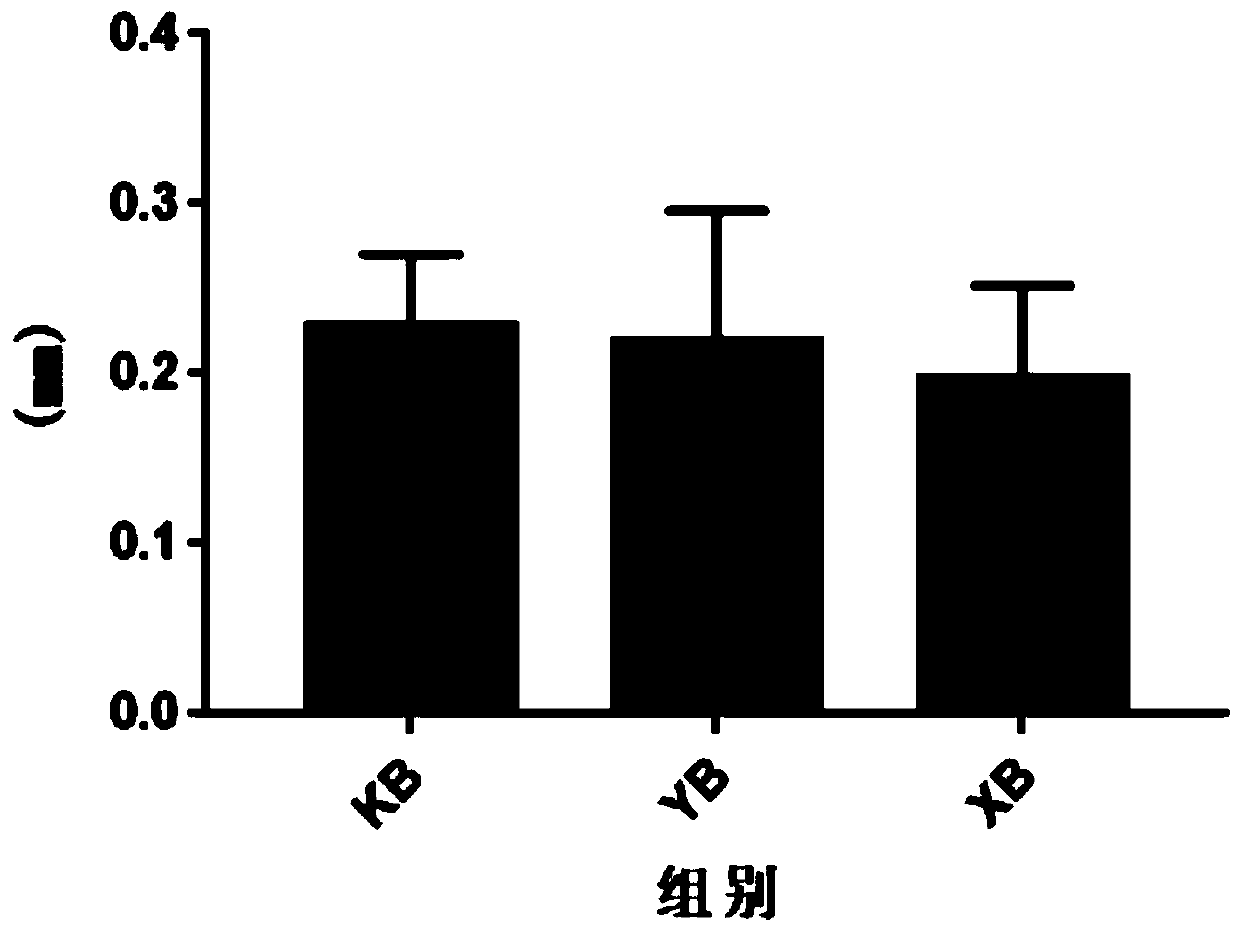

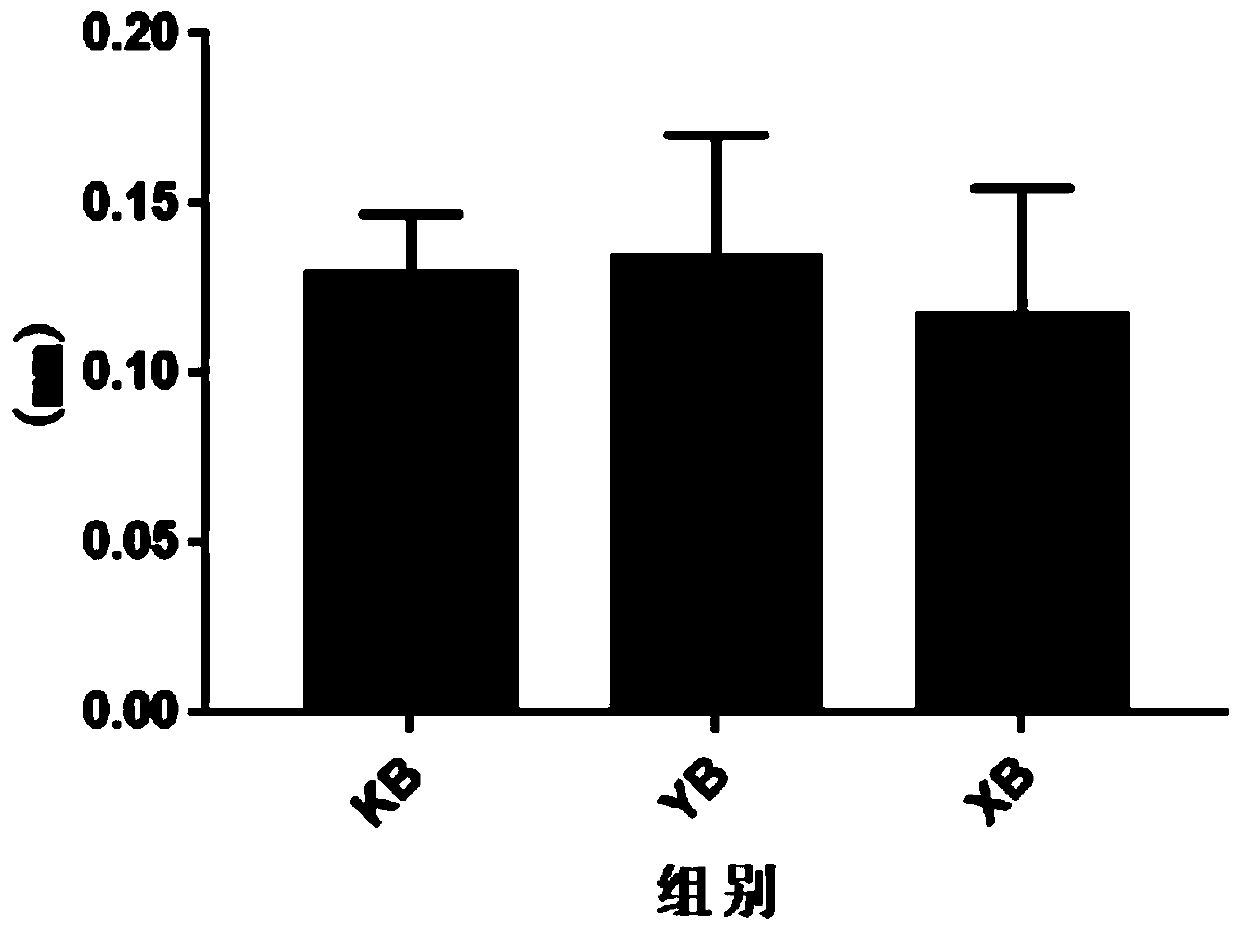

[0090] From the data in Table 2, it can be seen that when the weight ratio of the dietary fiber to the probiotic is 3 to 8:1, the dietary fiber in the preparation provides a protective landing site for the probiotic, so that the activity of the probiotic can be maintained during production, Optimum activity can be maintained during transportation and during the shelf life of the product. In order to further test the experiment of the improvement of the constipation and diarrhea of the mice by the probiotic preparation products of Examples 3-8, the mouse test of Example 12 was carried out, and the experimental process was the same as that of the mouse constipation and diarrhea experiment in Example 11 The process is consistent, and Table 7 shows the ink propulsion rate and diarrhea improvement rate and the ratio of raw materials in the probiotic preparation product during the mouse experiment of Examples 3-8.

[0091] Table 7 Example 3-8 probiotic preparation raw material rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Active | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com