Preparation method of waterproof composite fabric

A technology of composite fabrics and fabrics, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of reduced waterproof performance, poor waterproof performance, and reduced service life, so as to improve heat resistance and enhance Water-resistant, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

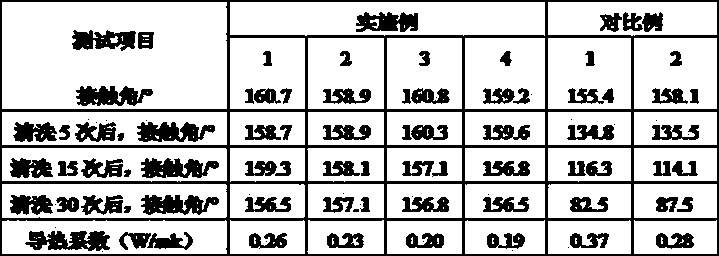

[0032] Embodiment 1~4: A kind of preparation method of waterproof composite fabric, described composite fabric comprises base fabric layer 1, outer fabric layer 2 and film layer 3, and the two sides of described film layer 3 pass adhesive agent and base fabric layer respectively 1 and the outer fabric layer 2 are bonded, and the film layer 3 is obtained by extrusion, forming, heating, stretching and annealing of the film material, and the film material is composed of the following components by weight:

[0033] components Example 1 Example 2 Example 3 Example 4 PTFE resin 100 95 90 88 Tetrafluoroethylene / perfluoroalkyl vinyl ether copolymer 14 13 17 20 1,4-trans polyisoprene rubber 9 7 13 10 Polymer of bis(4-fluorophenyl)methanone and 1,4-benzenediol 9 11 8.5 10 1,4-benzenediol 8 5 10 3 Potassium peroxodisulfate 1.5 2 0.8 2.5 Nano Titanium Dioxide Dispersion Slurry 1.0 3.9 5 2.8 2-Methyl-2-pent...

Embodiment 2

[0035] The silane coupling agent in embodiment 2 is the mixture of 3-aminopropyltriethoxysilane and aminopropylmethyldimethoxysilane;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap