Split modular biological fluidized composite reactor for sewage treatment

A technology of sewage treatment and biological fluidization, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the difficulties of on-site construction, insufficient structural strength, and limited sewage treatment capacity, etc. problems, to achieve the effect of flexible tower height setting, convenient construction, transportation and installation, and increased sewage treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

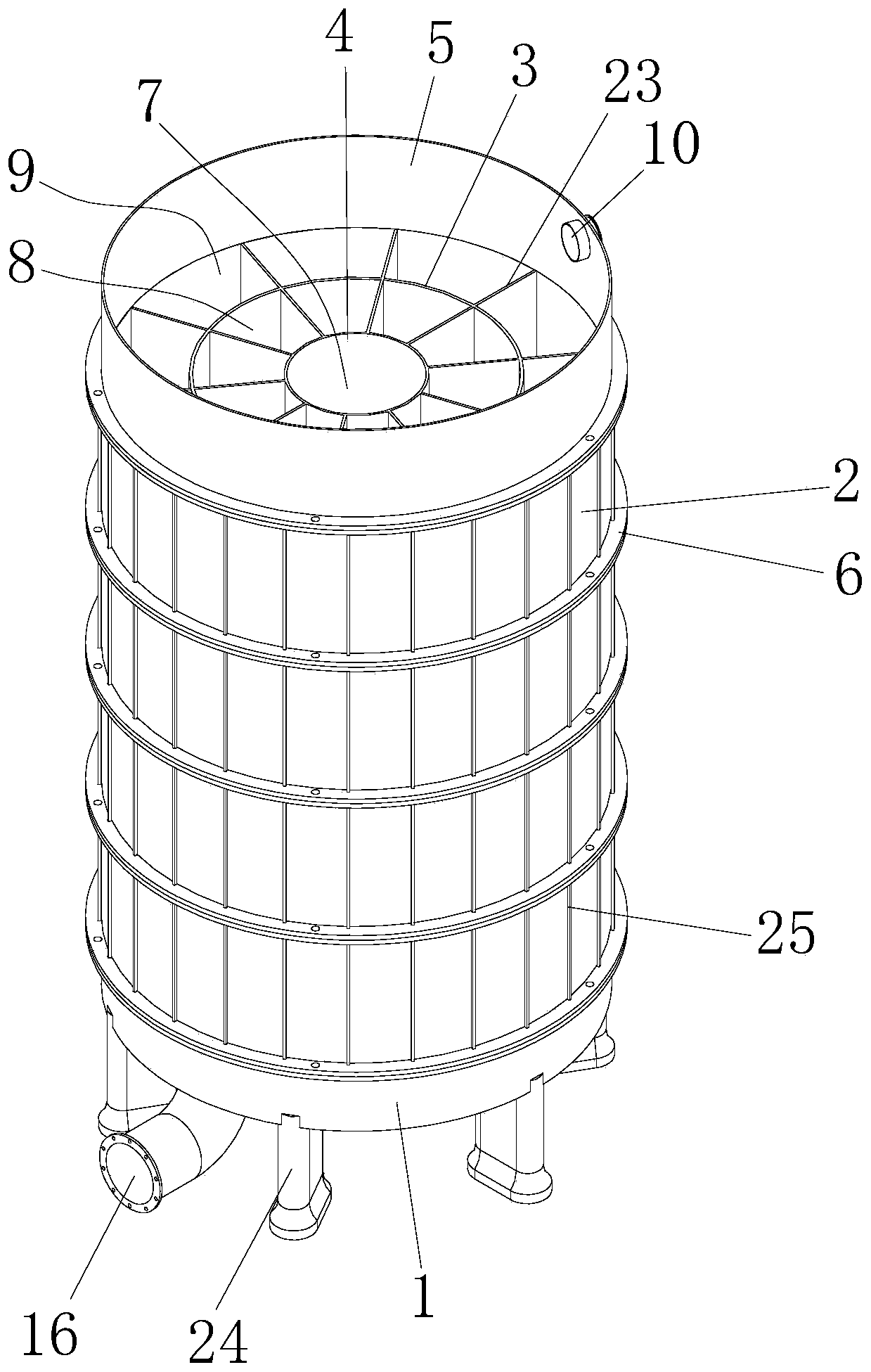

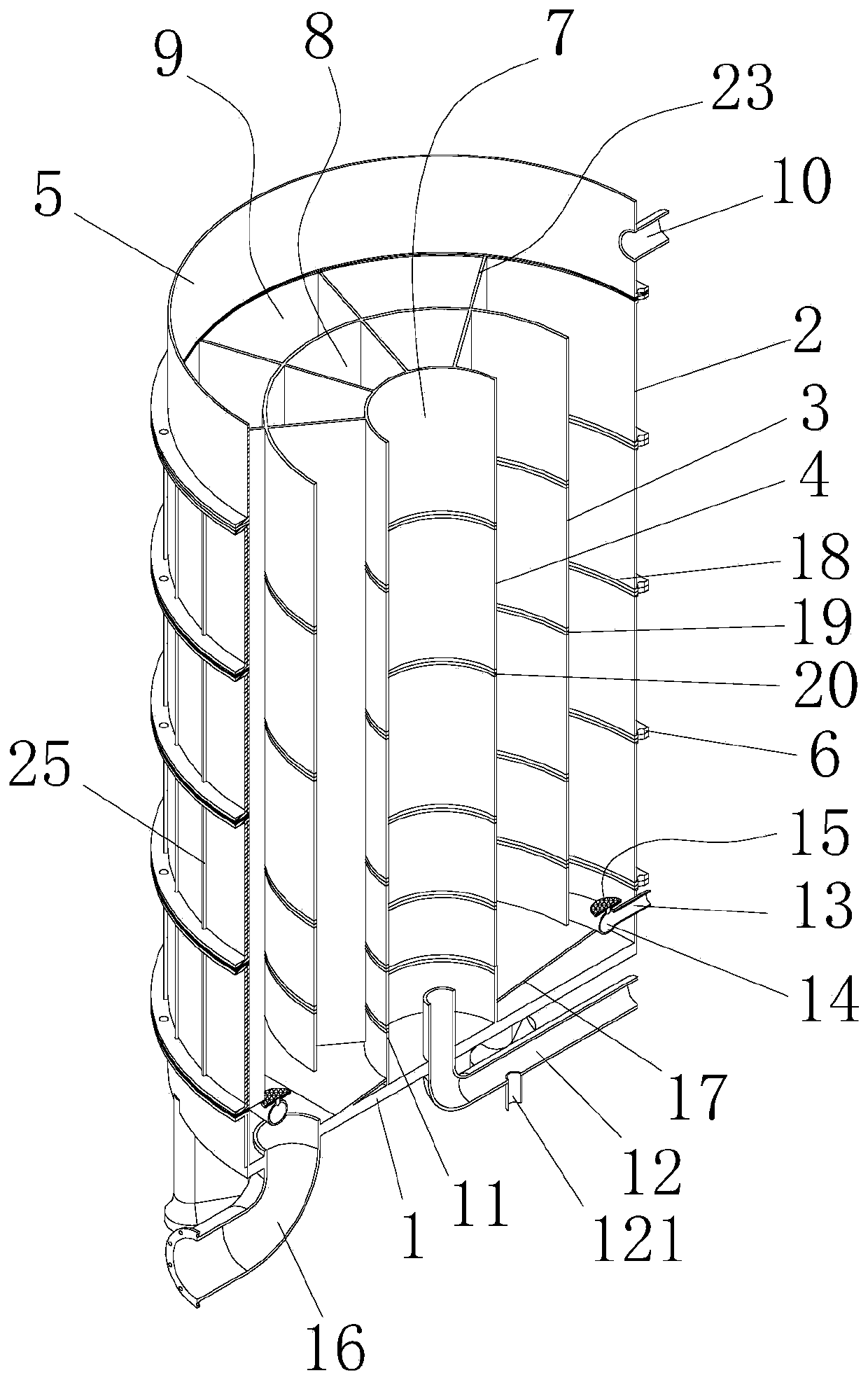

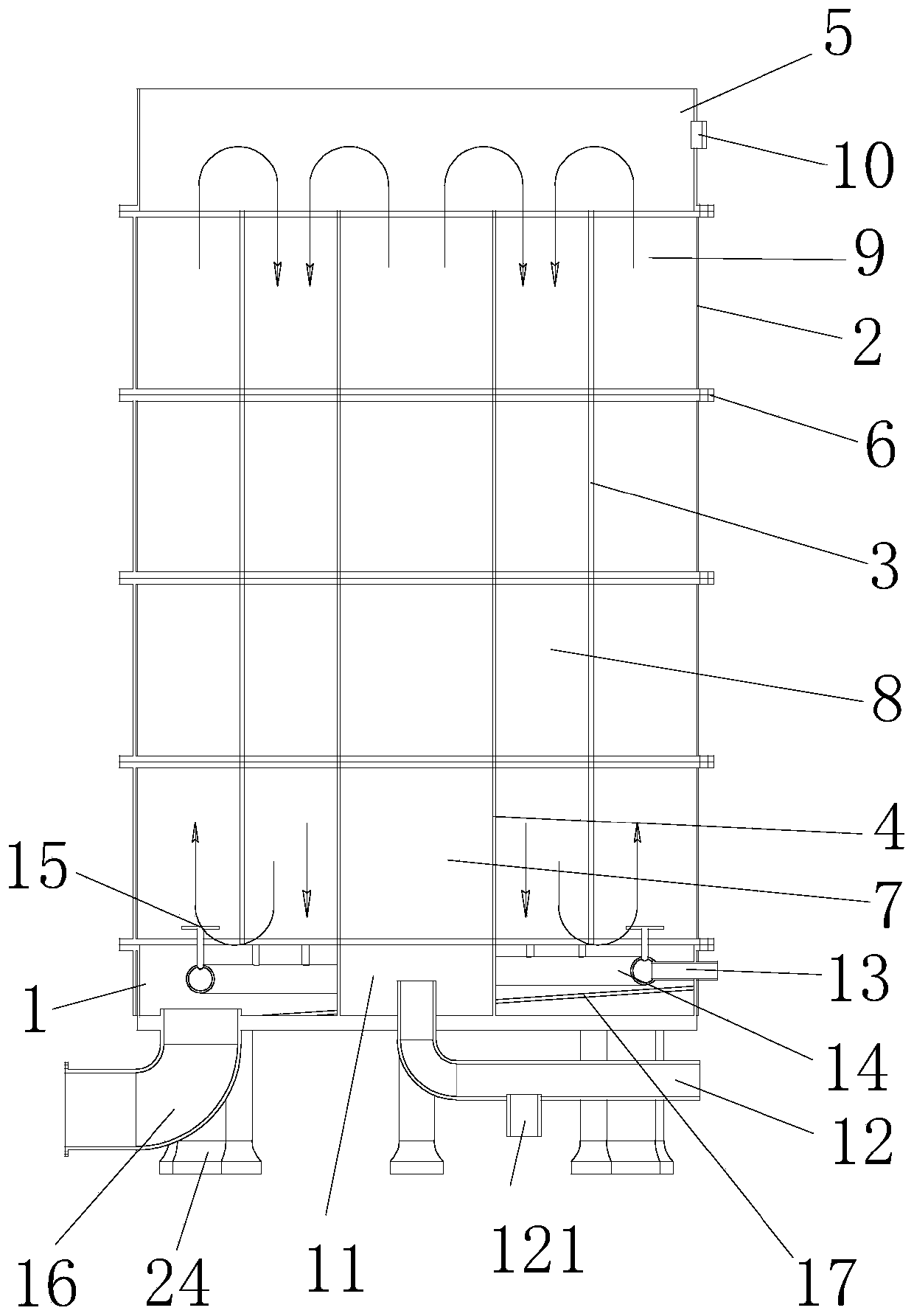

[0057] see Image 6 with 7 According to the actual sewage treatment capacity, select an appropriate number of tower units. When the reactor is specifically installed, the base cylinder 1 is fixed by the bracket leg 24 at the bottom, and then the multiple tower units and the clarifier cylinder are connected through the butt joint flange 6 5 are sequentially assembled on the base cylinder 1. During the docking process, the partitions 23 in adjacent tower units are arranged correspondingly to form an aerobic zone 9, anoxic zone 8 or good / deficient zones between adjacent tower units. The oxygen zone 7 is separated and connected independently by the partition plate 23 .

Embodiment 2

[0059] see Image 6 with 8 According to the actual sewage treatment capacity, select an appropriate number of tower units. When the reactor is specifically installed, the base cylinder 1 is fixed by the bracket leg 24 at the bottom, and then the multiple tower units and the clarifier cylinder are connected through the butt joint flange 6 5 are sequentially assembled on the base cylinder 1. During the docking process, the partitions 23 in adjacent tower units are arranged alternately to form an aerobic zone 9, anoxic zone 8 or good / deficient zones between adjacent tower units. The oxygen zone 7 is not separated by the partition 23, and the biological flora in each zone circulates with the sewage, thereby increasing the range of activities of the biological flora, which is beneficial to the improvement of the sewage treatment capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com