Flame-retardant nylon 66/nylon 6 composite material with high mechanical properties

A composite material, flame-retardant nylon technology, applied in the field of flame-retardant nylon 66/nylon 6 composite materials, can solve problems such as general strength, and achieve high mechanical properties and excellent flame-retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

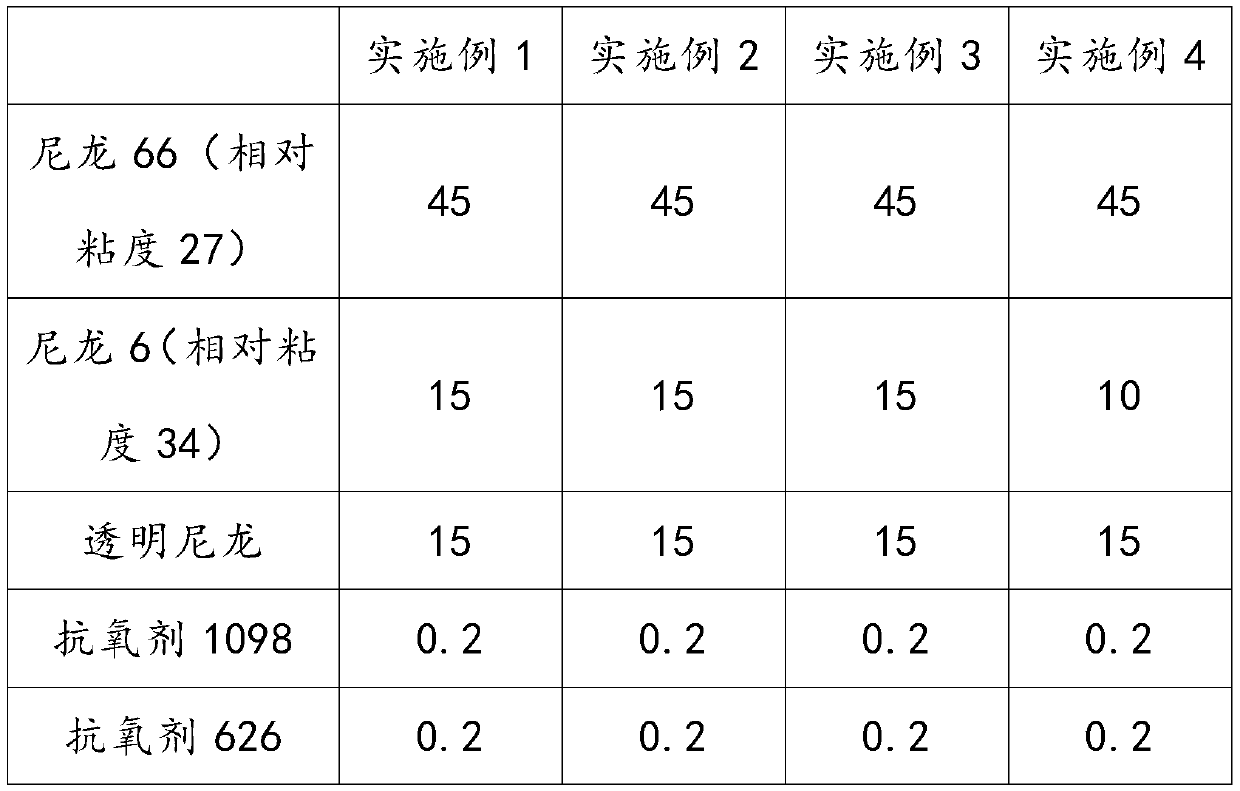

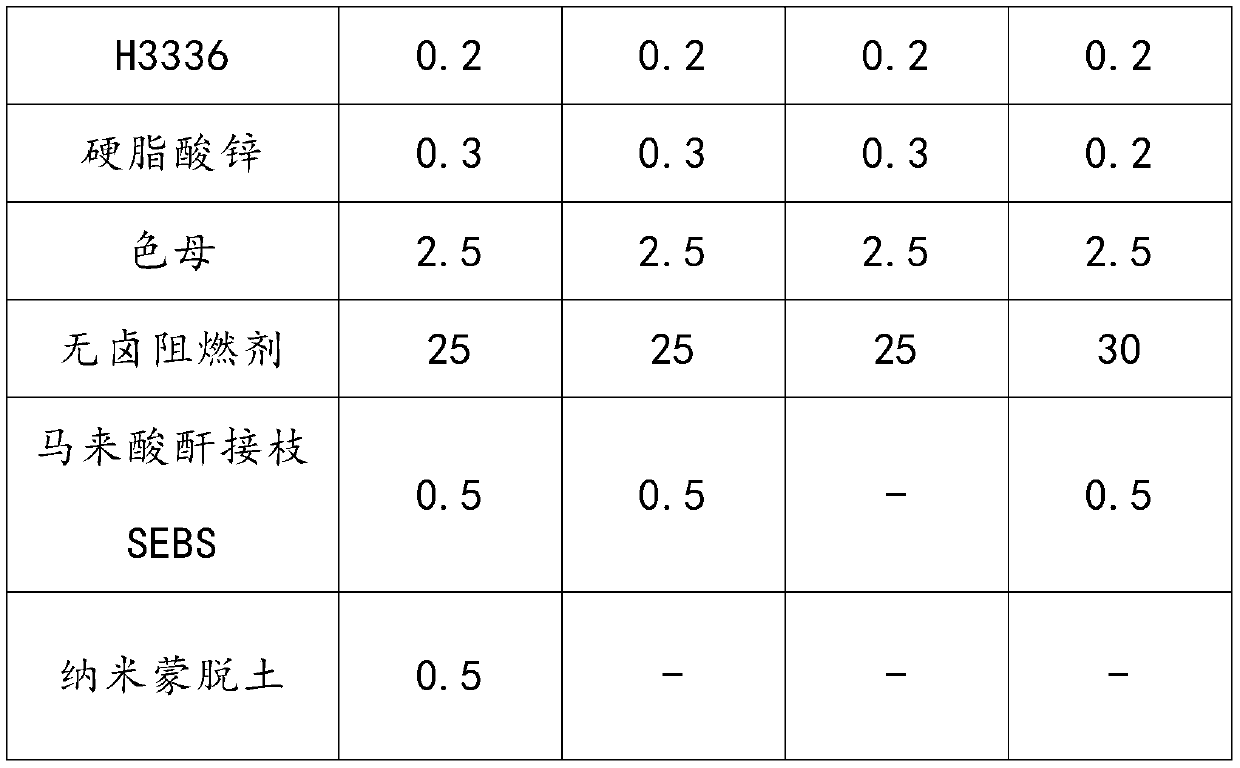

[0026] Weigh the raw materials according to the formula amount of Example 1 in the following table 1, first weigh the good nylon 66, nylon 6, and transparent nylon by weight, pour them into the stirring equipment, and mix them evenly; secondly, weigh the good anti-oxidant by weight Agent 1098, antioxidant 626, heat stabilizer H3336, zinc stearate, color masterbatch, halogen-free flame retardant, maleic anhydride grafted SEBS, nano-montmorillonite and the uniformly mixed materials are put into the mixer and mixed Uniform; then put the mixed material into the hopper of the twin-screw extruder, the working temperature of the extruder is between 120-350 °C, the speed is 200-600 rpm, melt extrusion, granulation and drying, A flame-retardant nylon 66 / nylon 6 composite material is obtained.

Embodiment 2

[0028] Weigh the raw materials according to the formula of Example 2 in Table 1 below, first weigh the nylon 66, nylon 6, and transparent nylon by weight, pour them into the mixing equipment, and mix them evenly; secondly, weigh the good antioxidant by weight Agent 1098, antioxidant 626, heat stabilizer H3336, zinc stearate, color masterbatch, halogen-free flame retardant, maleic anhydride grafted SEBS and the uniformly mixed materials are put into the mixer and mixed uniformly; then the mixed The good materials are put into the hopper of the twin-screw extruder. The working temperature of the extruder is between 120-350°C and the speed is 200-600 rpm. Melt extrusion, granulation and drying are carried out to obtain flame-retardant nylon 66 / Nylon 6 composite.

Embodiment 3

[0030] Weigh the raw materials according to the formula in Example 3 in Table 1 below, first weigh the nylon 66, nylon 6, and transparent nylon by weight, pour them into the mixing equipment, and mix them evenly; secondly, weigh the good anti-oxidant by weight Agent 1098, antioxidant 626, heat stabilizer H3336, zinc stearate, color masterbatch, halogen-free flame retardant and the uniformly mixed materials are put into the mixer and mixed evenly; then the mixed materials are put into the twin-screw extruder The feeding hopper of the extruder, the working temperature of the extruder is between 120-350 ° C, and the rotation speed is 200-600 rpm, melt extrusion, granulation and drying, to obtain a flame-retardant nylon 66 / nylon 6 composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com