Brewing method of retro liquor

A technology of liquor and distiller's yeast, which is applied in the preparation of alcoholic beverages, etc., can solve the problems of affecting the quality of liquor and liquor yield, poor culture and fermentation effects, and insufficient liquor fermentation, so as to improve blood circulation, remove blood stasis, and improve liquor quality, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

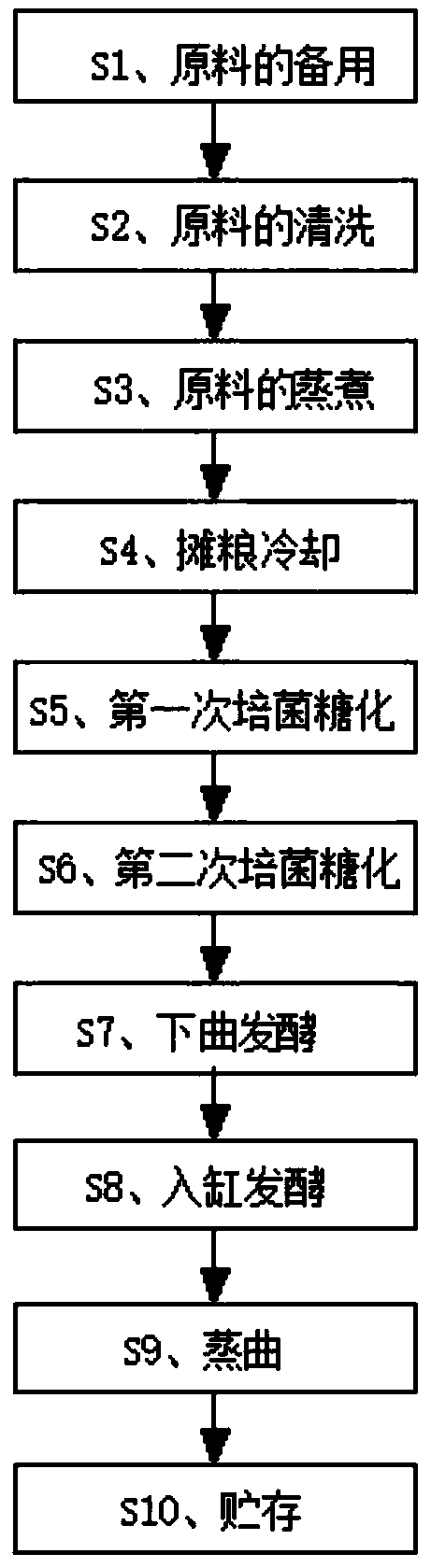

[0031] Example 1: Please refer to figure 1 , the invention discloses a brewing method of retro liquor, comprising the following steps:

[0032] S1, spare raw materials: 40 parts of corn, 30 parts of glutinous rice, 20 parts of peanut, 20 parts of wheat, 2 parts of rhizopus, 15 parts of distiller's yeast and 2 parts of glucoamylase;

[0033] S2. Cleaning of raw materials: select corn, glutinous rice, peanuts and wheat with full grains and no rot and mildew to clean, add clear water to the cooking pot, and put the cleaned corn, glutinous rice, peanuts and wheat into the cooking pot for soaking;

[0034] S3. Cooking of raw materials: Mix the corn, glutinous rice, peanuts and wheat soaked in step S1 evenly, put them in a cooking pot, cover and steam for 50 minutes, open the cover and steam for 15 minutes until cooked, add cold water after steaming Soak it until it blooms, then drain the water and set aside;

[0035] S4. Grain spreading and cooling: the steamed raw materials obta...

Embodiment 2

[0049] Example 2: Please refer to figure 1, the invention discloses a brewing method of retro liquor, comprising the following steps:

[0050] S1, spare raw materials: 40 parts of corn, 30 parts of glutinous rice, 20 parts of peanut, 20 parts of wheat, 2 parts of rhizopus, 15 parts of distiller's yeast and 2 parts of glucoamylase;

[0051] S2. Cleaning of raw materials: select corn, glutinous rice, peanuts and wheat with full grains and no rot and mildew to clean, add clear water to the cooking pot, and put the cleaned corn, glutinous rice, peanuts and wheat into the cooking pot for soaking;

[0052] S3. Cooking of raw materials: Mix the corn, glutinous rice, peanuts and wheat soaked in step S1 evenly, put them in a cooking pot, cover and steam for 55 minutes, open the cover and steam for 17 minutes until cooked, add cold water after steaming Soak it until it blooms, then drain the water and set aside;

[0053] S4. Grain spreading and cooling: the steamed raw materials obtai...

Embodiment 3

[0067] Example 3: Please refer to figure 1 , the invention discloses a brewing method of retro liquor, comprising the following steps:

[0068] S1, spare raw materials: 40 parts of corn, 30 parts of glutinous rice, 20 parts of peanut, 20 parts of wheat, 2 parts of rhizopus, 15 parts of distiller's yeast and 2 parts of glucoamylase;

[0069] S2. Cleaning of raw materials: select corn, glutinous rice, peanuts and wheat with full grains and no rot and mildew to clean, add clear water to the cooking pot, and put the cleaned corn, glutinous rice, peanuts and wheat into the cooking pot for soaking;

[0070] S3. Cooking of raw materials: Mix the corn, glutinous rice, peanuts and wheat soaked in step S1 evenly, put them into the cooking pot and cover and steam for 60 minutes, then open the cover and steam for 20 minutes until cooked, add cold water after steaming Soak it until it blooms, then drain the water and set aside;

[0071] S4. Grain spreading and cooling: the steamed raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com