Construction structure of exterior facade black brick decoration and construction method

A technology for exterior facades and blue bricks, applied to building components, building structures, walls, etc., can solve problems such as difficult quality control, processing noise pollution, general decoration effects, etc., to achieve convenient and fast assembly, save construction time, and reduce maintenance the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

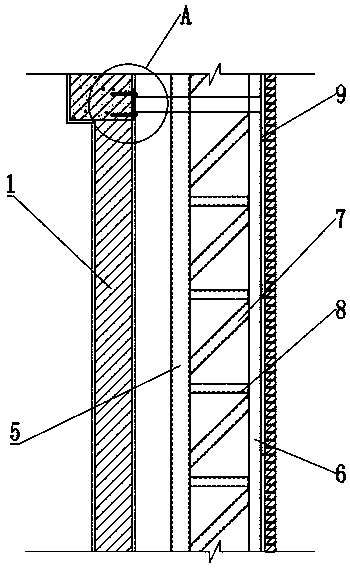

[0037] Step 1. According to the building shape, design the support system of the blue brick dry-hanging curtain wall, determine the number and position of the fixed points on the wall, the size of the square steel pipe, and the connection method;

[0038] Step 2. Prepare the required materials: including steel pipes, angle irons 9, steel plates 2, mechanical anchor bolts 3, green bricks, etc., and use cutting machines to process them into the required size for design;

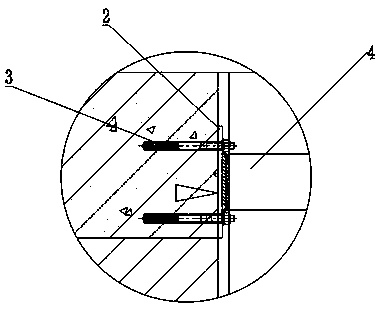

[0039] Step 3. Use the total station to determine the fixed point position on the original building facade 1, use a hammer chisel to remove the surface decoration layer within the fixed range of the steel plate 2, and clean it with a brush after exposing the concrete structure layer, and check whether the base surface structure is damaged. Cracks, if any cracks need to be reinforced;

[0040] Step 4. Manually install the 300x200x10mm steel plate 2 at the determined fixed point, open a hole in each of the four c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com