Control system for cooling of rectification type auto-cascade refrigeration system

A refrigeration system and control system technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high power consumption of heating capacity compressors, different optimal concentrations, and threats to pipeline pressure safety, etc., to achieve fast Cooling rate, reduction of power consumption, and effects of heating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further specifically described in detail below in conjunction with specific embodiments.

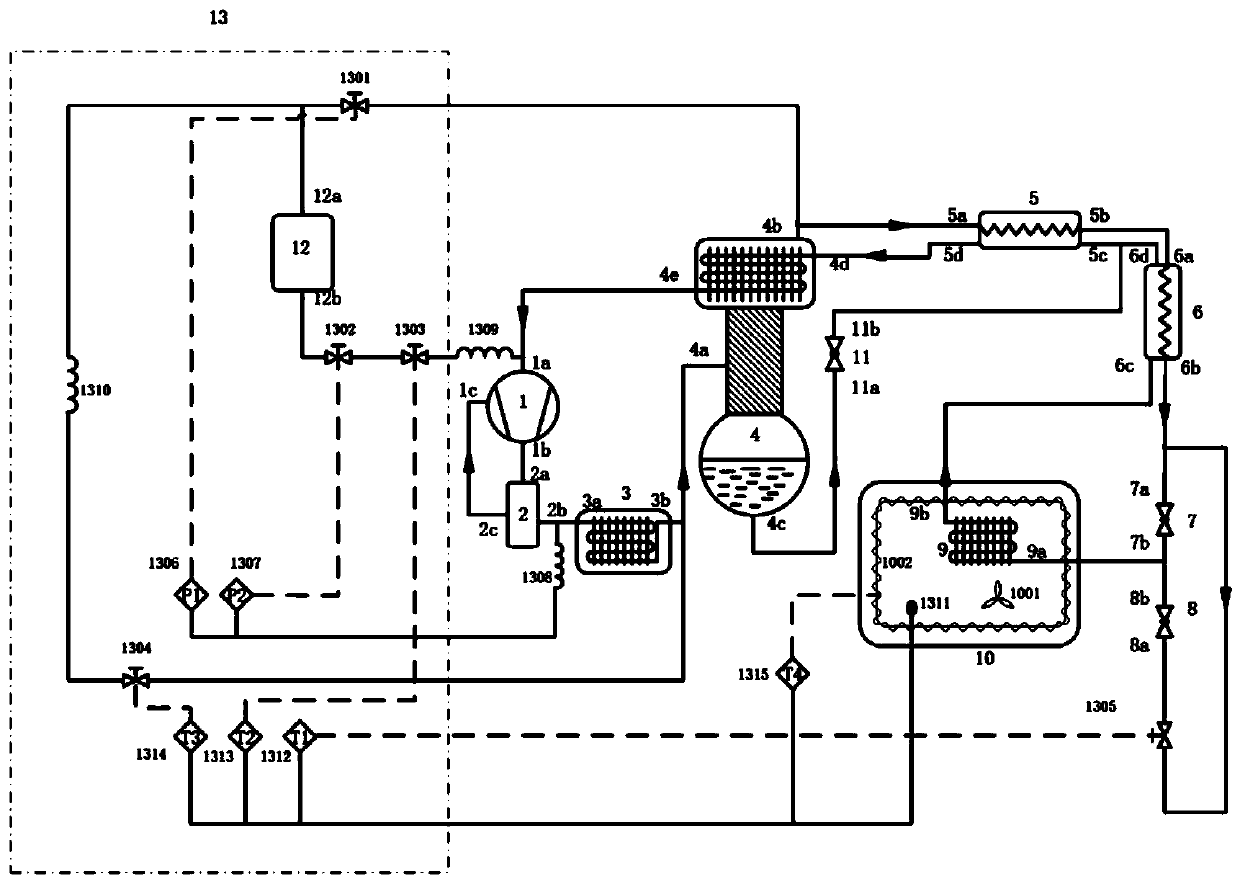

[0045] like figure 1 As shown, the rectification type self-cascading refrigeration system provided by the present invention includes a compressor 1, an oil separator 2, a condenser 3, a rectification device 4, a high-temperature regenerator 5, a low-temperature regenerator 6, a first main section Throttle valve 7, second main throttle valve 8, evaporator 9, cold box 10, sub-throttle valve 11, air storage tank 12 and control system 13.

[0046] The components are connected by pipelines, and the connection relationship on the high-pressure side is: the exhaust port 1b of the compressor 1 is connected to the inlet 2a of the oil separator 2, and the outlet 2b of the oil separator 2 is connected to the inlet 3a of the condenser 3 , the oil return port 2c of the oil separator 2 is connected with the oil return port 1c of the compressor 1, the outlet 3b of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com