High-compaction-resistant composite conductive agent and application thereof in lithium ion battery

A composite conductive agent and high-voltage-resistant technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor lithium ion transmission and migration, limited production capacity, complex process, etc., and achieve improved cycle stability , improve compaction resistance, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

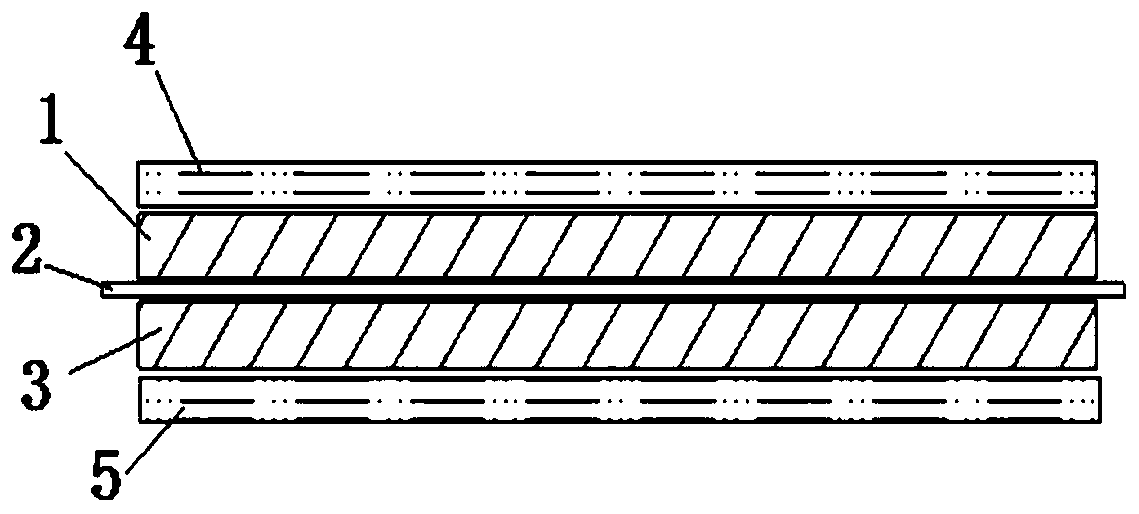

[0042] The present embodiment provides a kind of lithium-ion battery (rated capacity 2.7Ah), comprises positive pole piece and negative pole piece; The coating of described positive pole piece comprises the raw material of following mass percentage content:

[0043] Composite conductive agent 2.2%

[0044] PVDF 2.5%

[0045] High nickel 811 material 95.3%;

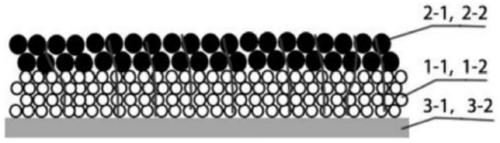

[0046] Wherein, the composite conductive agent is formed by mixing components including the following mass percentages: microporous carbon 68.2%, carbon nanotubes 31.8%;

[0047] The positive pole piece (density 20mg / cm 2 ) is prepared as follows:

[0048] (1) configure glue;

[0049] (2) Stir evenly after mixing the composite conductive agent, binding agent and active material to obtain a mixed powder;

[0050] (3) adding the mixed powder into the glue to obtain a slurry;

[0051] (4) The slurry is coated on both sides of the current collector, and rolled after drying (compaction density 3.5g / cm 3 ).

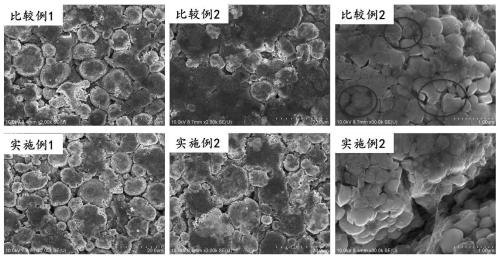

[0052] The co...

Embodiment 2

[0060] This embodiment provides a lithium-ion battery, the difference from Embodiment 1 is that the compacted density of the positive pole piece is 3.7 g / cm 3 .

Embodiment 3

[0062] This embodiment provides a lithium-ion battery, and the difference from Embodiment 1 is that the coating of the negative electrode sheet includes the following raw materials in mass percentage:

[0063]

[0064] Wherein, the composite conductive agent is formed by mixing components including the following mass percentages: 66.7% of microporous carbon and 33.3% of carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com