a kind of cuins 2 Quantum dot/bioi composite photocatalyst and its preparation method and application

A photocatalyst, cuins2 technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of poor stability, limited application, difficult recovery, etc., achieve good contact, easy operation, and improved The effect of effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

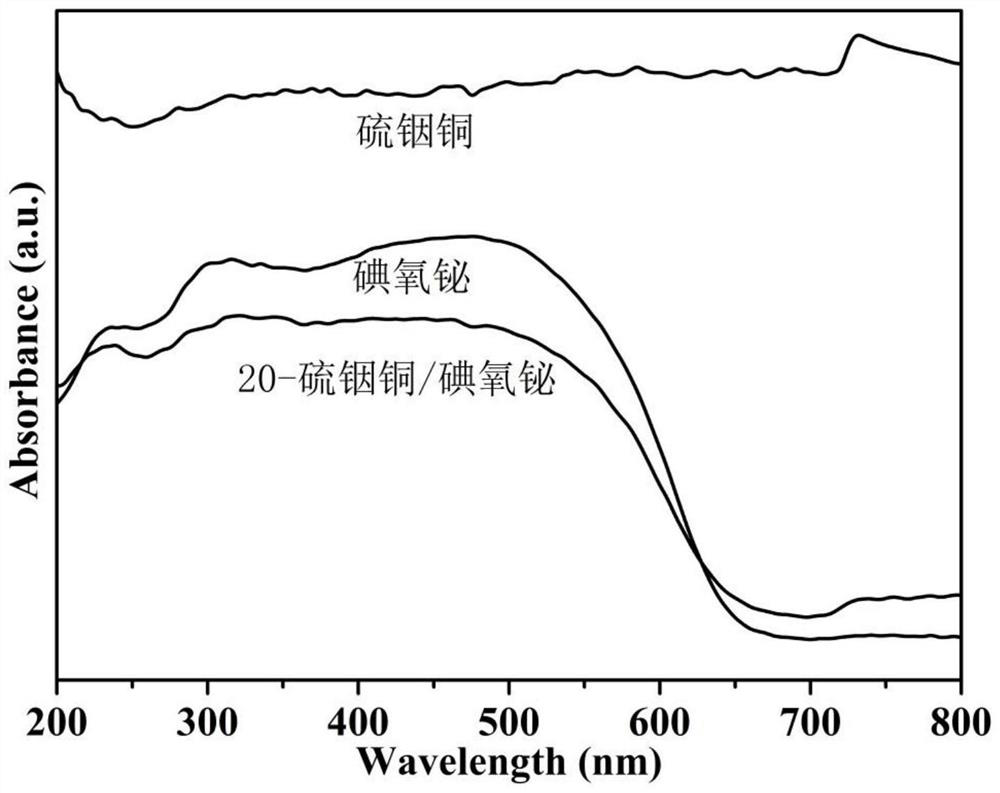

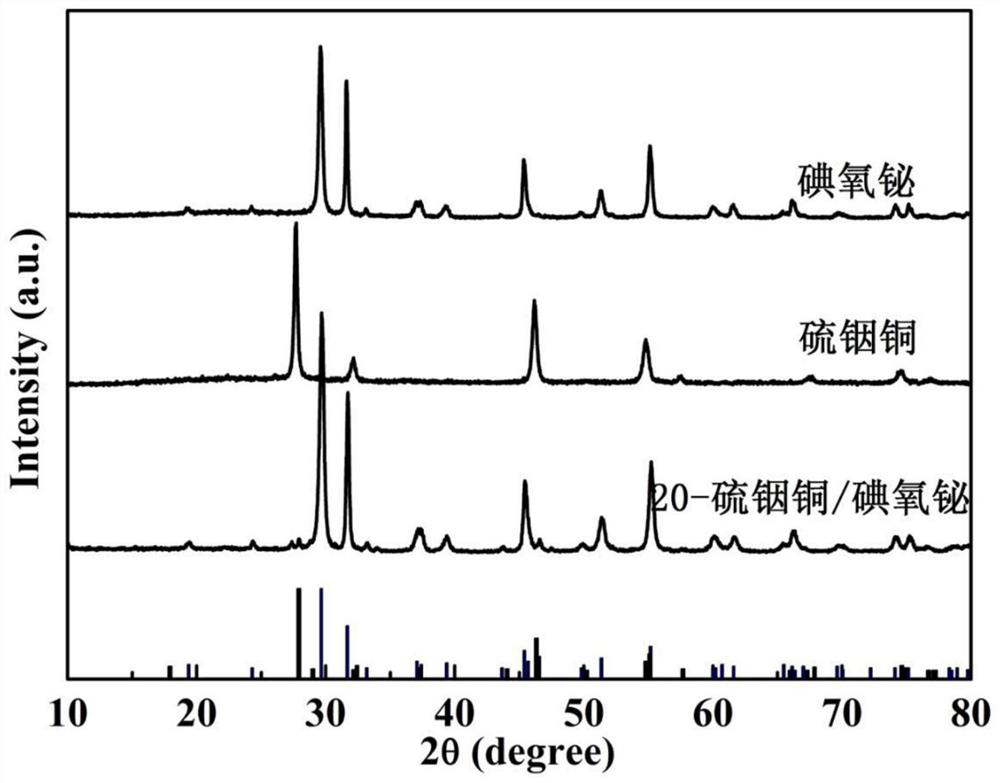

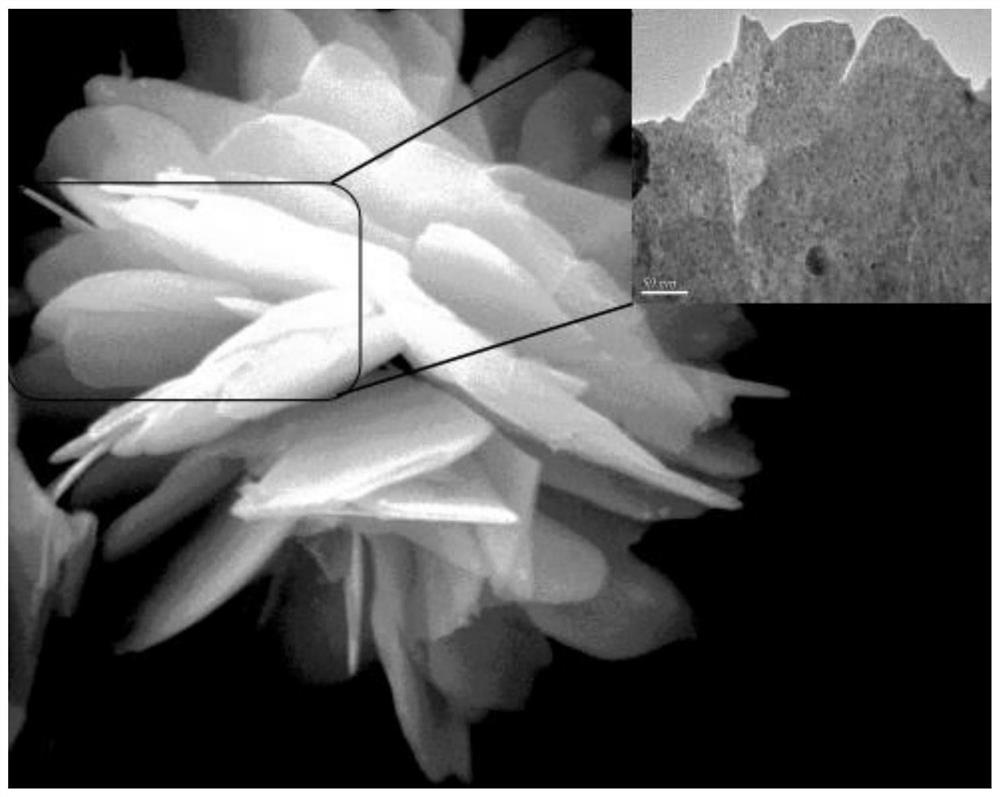

[0028] (1) CuInS 2 Preparation of quantum dot photocatalyst:

[0029] Put 0.17g of copper chloride dihydrate and 20mL of ethylenediamine into a small beaker, dissolve them all, add 0.22g of indium chloride and 0.24g of L-cysteine, add 20ml of deionized water and magnetically stir to assist the reaction 30min; Pour into a high-pressure reaction kettle and heat at 180°C for 12h in a blast drying oven, take it out and let it cool naturally, centrifuge, wash with deionized water and ethanol three times each, put it into a blast drying oven to dry, and obtain CuInS 2 Quantum dot photocatalyst.

[0030] (2) CuInS 2 Preparation of quantum dot-supported BiOI composite photocatalyst:

[0031] Weigh 0.485mg of bismuth nitrate and 0.166g of potassium iodide into a small beaker, respectively, add 20ml of absolute ethanol, 30ml of deionized water, stir magnetically until completely dissolved, then mix the above two solutions, and then add 0.025g of step (1 ) CuInS prepared in2 Quantum ...

Embodiment 2

[0034] (1) CuInS 2 Preparation of quantum dot photocatalyst:

[0035] Put 0.17g of copper chloride dihydrate and 20mL of ethylenediamine into a small beaker, dissolve them all, add 0.22g of indium chloride and 0.24g of L-cysteine, add 20ml of deionized water and magnetically stir to assist the reaction 30min; Pour into a high-pressure reaction kettle and heat at 200°C for 18h in a blast drying oven, take it out and let it cool naturally, then centrifuge, wash with deionized water and ethanol three times each, put it into a blast drying oven to dry, and obtain CuInS 2 Quantum dot photocatalyst.

[0036] (2) CuInS 2 Preparation of quantum dot-supported BiOI composite photocatalyst:

[0037] Weigh 0.485mg of bismuth nitrate and 0.166g of potassium iodide into a small beaker, respectively, add 20ml of absolute ethanol, 20ml of deionized water, stir magnetically until completely dissolved, and then mix the above two solutions. Then add 0.05g of CuInS 2 The quantum dots were fu...

Embodiment 3

[0043] (1) CuInS 2 Preparation of quantum dot photocatalyst:

[0044] Put 0.17g of copper chloride dihydrate and 30mL of ethylenediamine into a small beaker, dissolve them all, add 0.22g of indium chloride and 0.24g of L-cysteine, add 30ml of deionized water and magnetically stir to assist the reaction 30min; Pour into a high-pressure reaction kettle and heat at 190°C for 15h in a blast drying oven, take it out and let it cool naturally, centrifuge, wash with deionized water and ethanol three times each, put it into a blast drying oven to dry, and obtain CuInS 2 Quantum dot photocatalyst.

[0045] (2) CuInS 2 Preparation of quantum dot-supported BiOI composite photocatalyst:

[0046] Weigh 0.485mg of bismuth nitrate and 0.166g of potassium iodide into a small beaker, respectively, add 20ml of absolute ethanol, 40ml of deionized water, stir magnetically until completely dissolved, and then mix the above two solutions. Then add 0.1g of CuInS 2 After the quantum dots were fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com