Cylindrical grinding machine

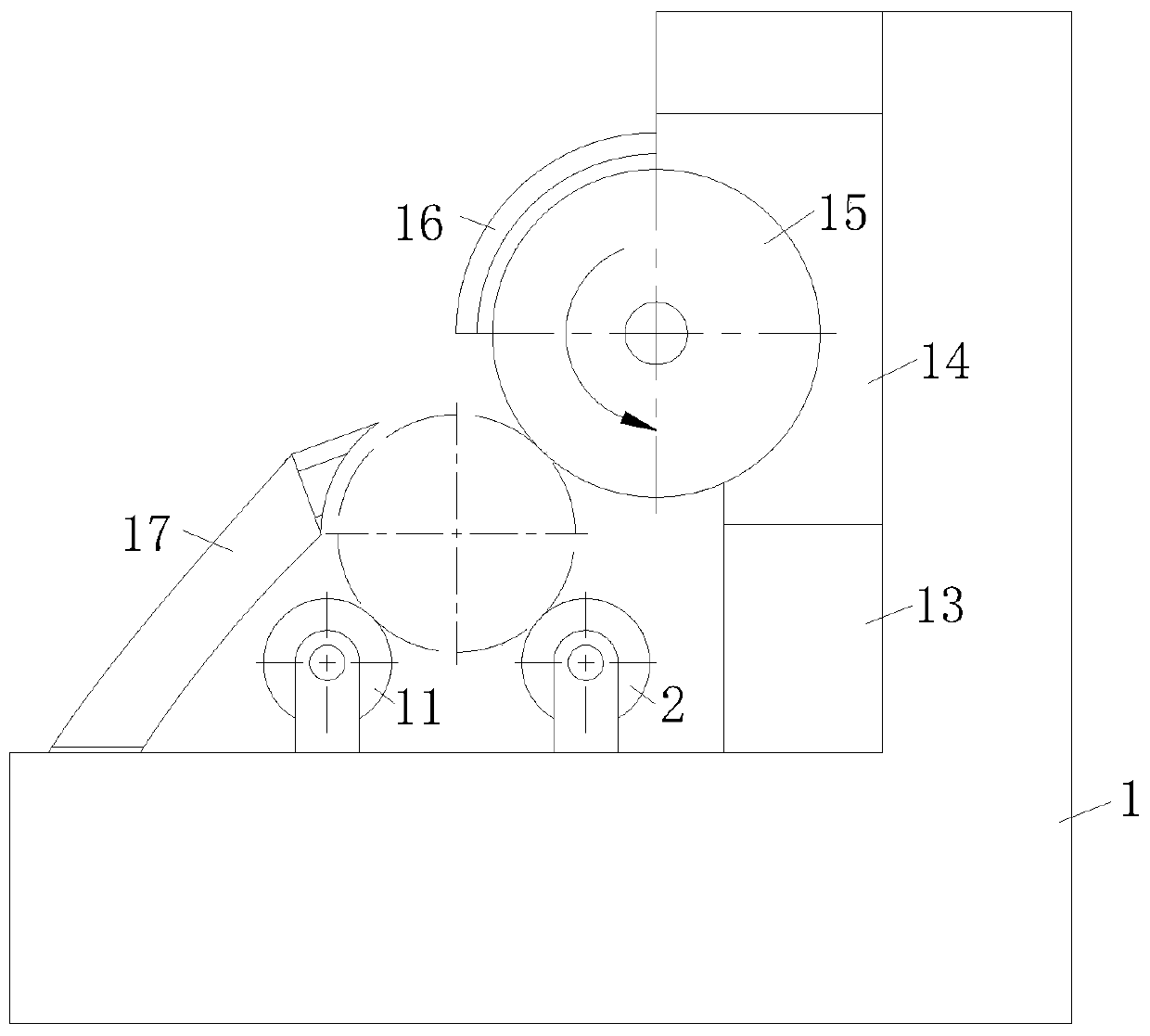

A cylindrical grinding machine, No. 1 technology, applied in grinding machines, machine tools designed for grinding the rotating surface of workpieces, grinding/polishing equipment, etc., can solve the problems of reducing the service life of water pumps, single cooling liquid spraying methods, and cooling liquid splashing Waste and other issues, to achieve the effect of increasing grinding quality, reducing spatter, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

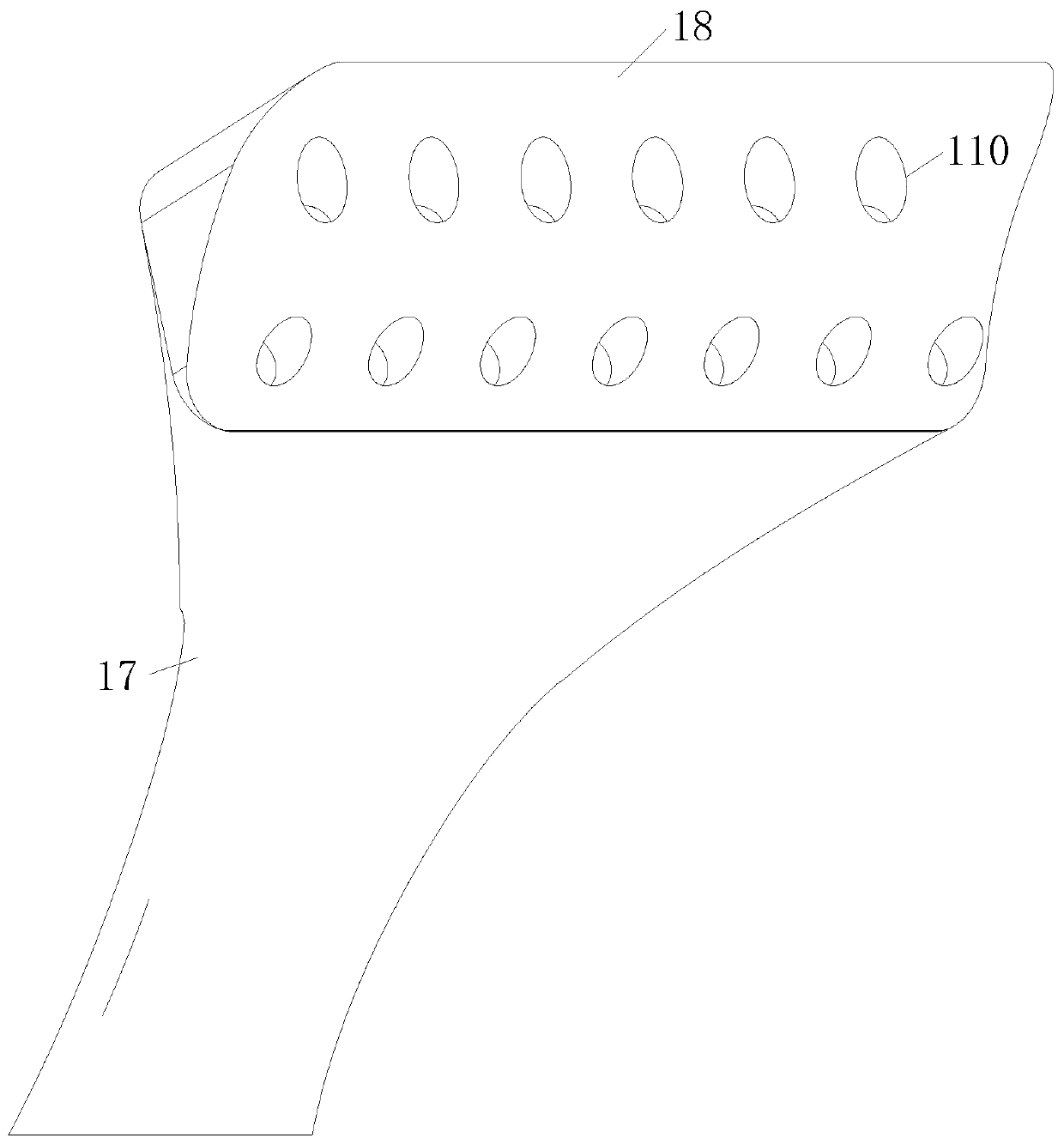

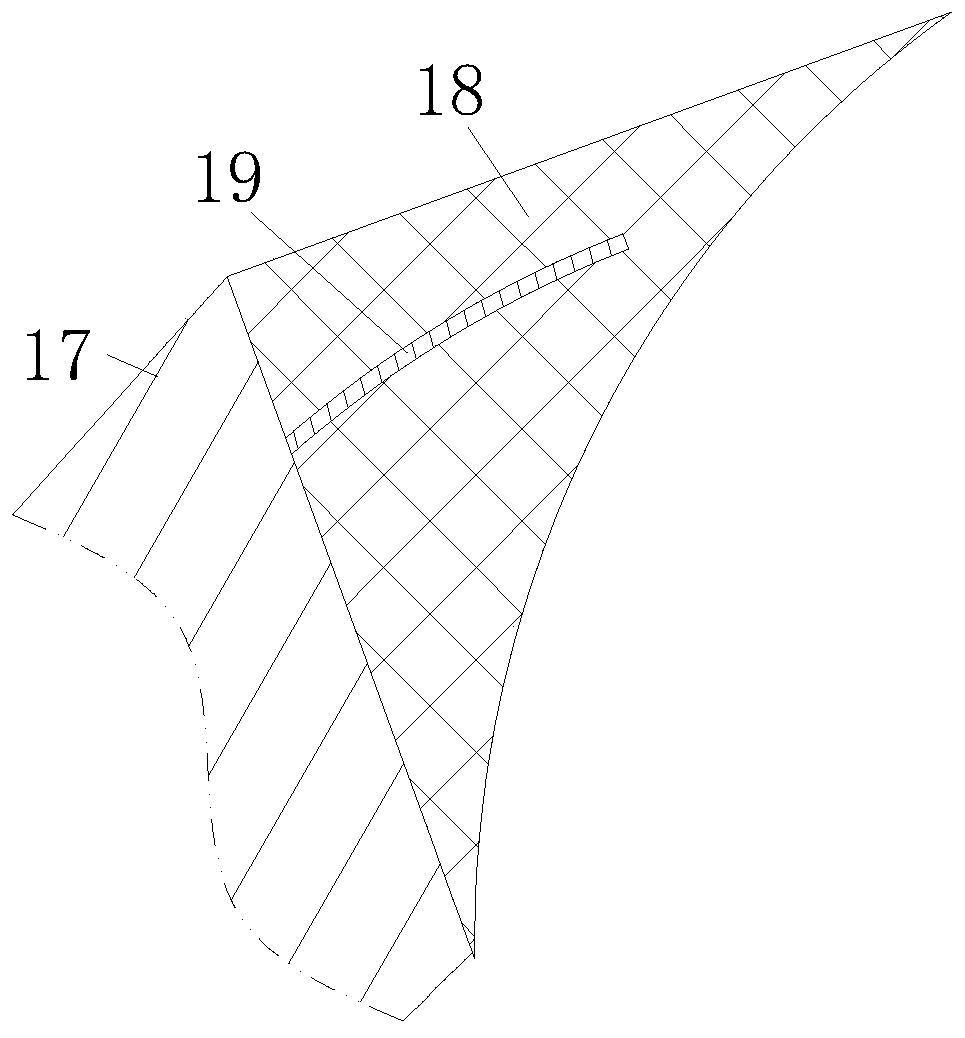

[0025]As an embodiment of the present invention, the arc-shaped portion 18 is made of elastic wear-resistant rubber, thereby increasing the fit between the arc-shaped portion 18 and the workpiece 12, so that the cooling liquid sprayed by the nozzle 17 is evenly dispersed on the workpiece 12 surface to increase the cooling efficiency of the workpiece 12; the arc portion 18 is inlaid with a group of elastic steel plates 19, and the steel plate close to the nozzle 17 is fixedly connected with the nozzle 17, and the support force of the arc portion 18 is improved through the elastic steel plate 19 , to further increase the fit between the arc portion 18 and the workpiece 12, increase the cooling efficiency of the workpiece 12, and further increase the cooling efficiency of the workpiece 12; the arc portion 18 made of wear-resistant elastic rubber increases the nozzle 17 and the workpiece 12, while reducing the scratches on the surface of the workpiece 12 by the arc-shaped part 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com