A kind of daf and dnp eutectic explosive and preparation method thereof

A eutectic explosive, orthorhombic technology, which is applied to explosives processing equipment, explosives, explosive compound components, etc., can solve the problems of poor comprehensive performance, low oxygen content, low density, etc., and achieve increased crystal density and good explosion. Boom performance, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

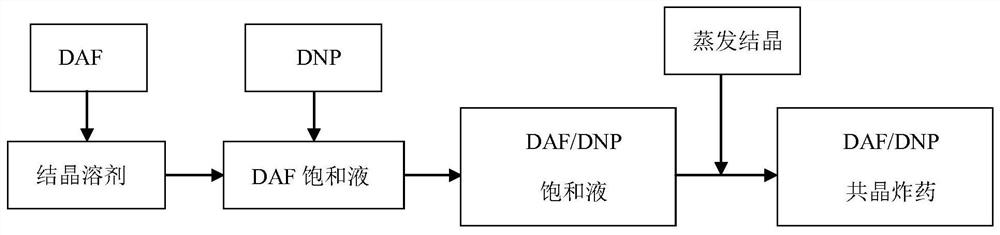

[0022] (1) Preparation of DAF and DNP solution

[0023] Dissolve a sufficient amount of DAF in a solvent, dissolve at a temperature of 20-50°C, and filter to obtain a DAF saturated solution; add sufficient DNP to the DAF saturated solution to dissolve, and filter to obtain a DAF and DNP saturated solution.

[0024] (2) Preparation of DAF and DNP eutectic explosive

[0025] Transfer the DAF / DNP solution to a beaker, then place the beaker in a constant temperature box, slowly evaporate the solvent at a certain temperature, filter and dry to obtain the DAF / DNP eutectic explosive.

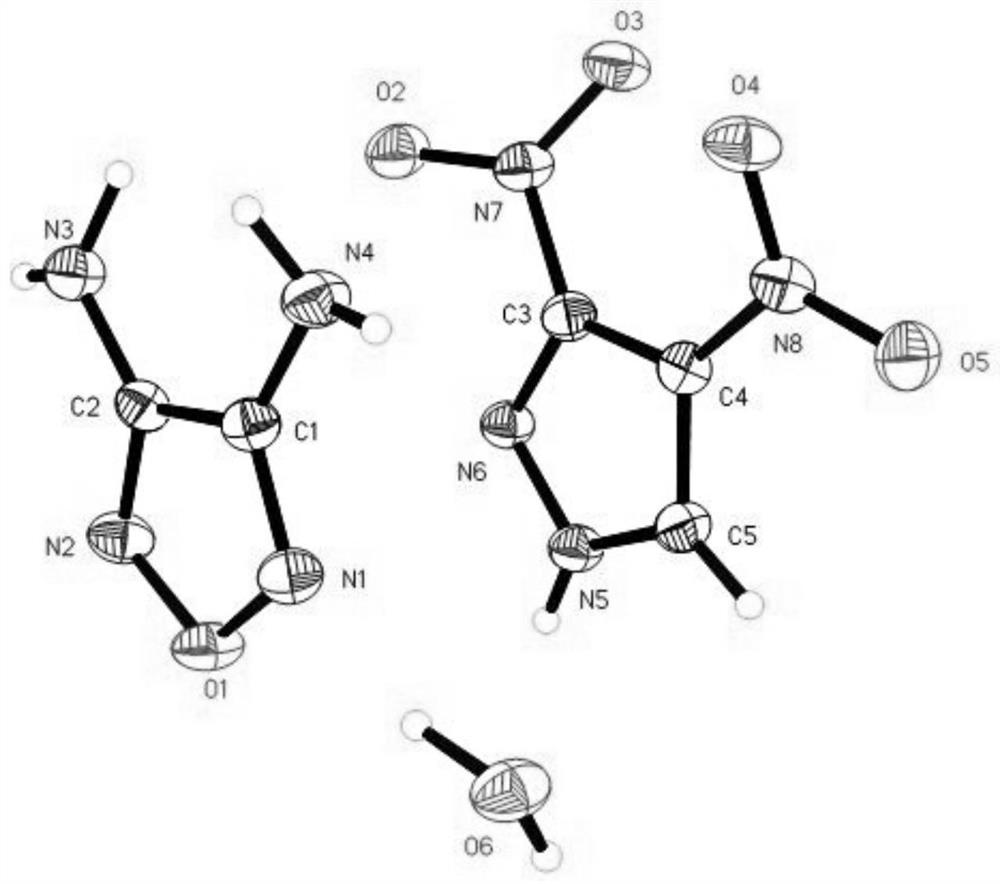

[0026] figure 2 A diagram showing the molecular structure of the DAF / DNP co-crystal explosive confirmed by single crystal diffraction (SXRD). From the SXRD analysis results, it can be seen that the DAF molecules, DNP molecules, H 2 The molar ratio of O molecules is 1:1:1. The molecular formula of the eutectic is C 5 h 8 N 8 o 6 , belonging to the orthorhombic crystal system, P2 1 2 1 2 1 Sp...

Embodiment 1

[0036] At 20°C, add 10ml of industrial ethanol into a three-necked flask, add a sufficient amount of DAF, start stirring, dissolve, and filter to obtain a saturated DAF solution. Then add a sufficient amount of DNP to the above solution, stir, dissolve, and filter to obtain a saturated solution of DAF and DNP. Transfer the saturated solution of DAF and DNP to a beaker, slowly volatilize the solvent in a thermostat at 20°C, and precipitate crystals, filter and dry to obtain DAF / DNP eutectic explosive.

Embodiment 2

[0038] At 30°C, add 20ml of industrial acetonitrile into a three-necked flask, add a sufficient amount of DAF, start stirring, dissolve, and filter to obtain a saturated DAF solution. Then add a sufficient amount of DNP to the above solution, stir, dissolve, and filter to obtain a saturated solution of DAF and DNP. Transfer the saturated solution of DAF and DNP to a beaker, slowly volatilize the solvent in a thermostat at 30°C, precipitate crystals, filter and dry to obtain DAF / DNP eutectic explosive.

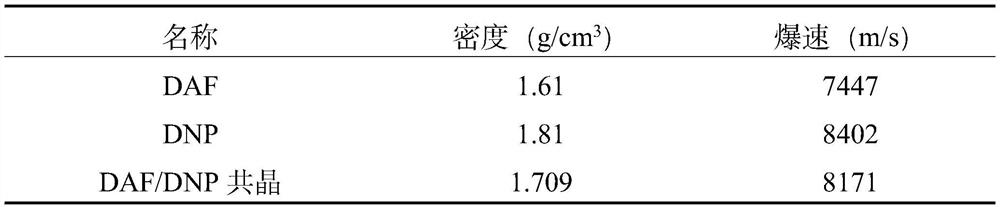

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com