Preparation method of cationic hydrogel

A technology of cationic hydrogel and cationic starch, applied in the field of pharmaceutical dosage forms, can solve problems such as being unsuitable for large-scale production and application, and achieve the effects of cheap raw materials, easy availability of raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

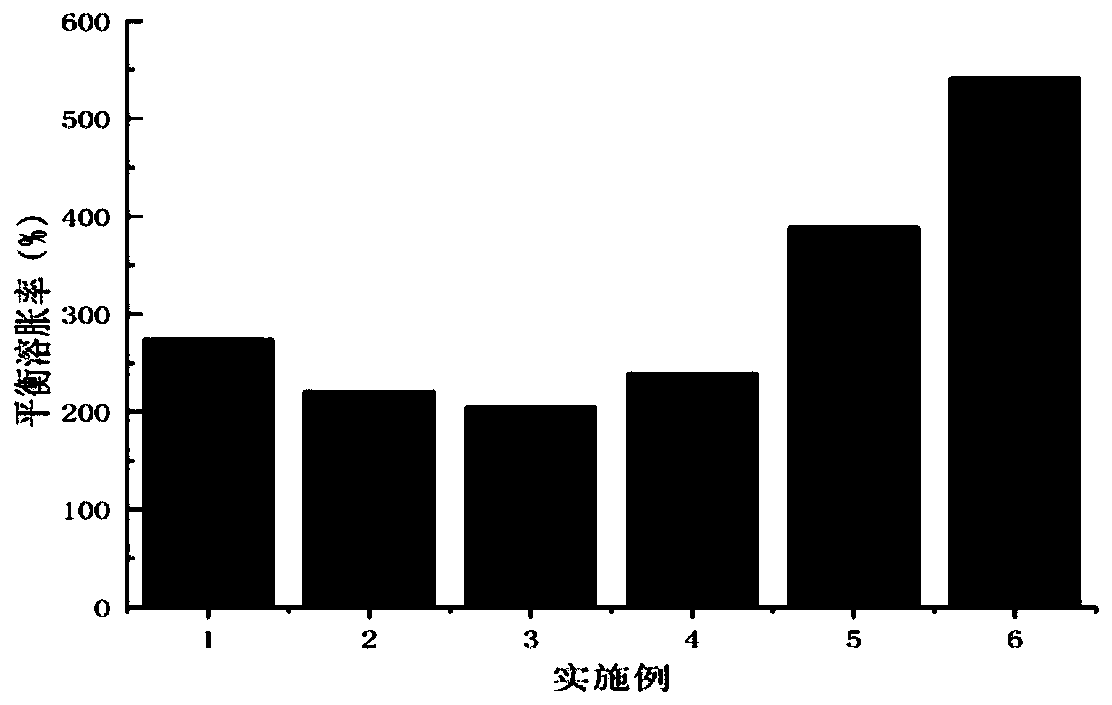

Embodiment 1

[0027] A kind of preparation of cationic hydrogel, its preparation method comprises the following steps:

[0028] (1) Mix 10g of polyvinyl alcohol and 2g of cationic starch and dissolve in 100mL of water, stir and heat at 90°C for 2h, mix the polymer completely, and dissolve in water.

[0029] (2) The polymer aqueous solution was poured into the mold, frozen at -25°C for 16 hours, thawed at 25°C for 8 hours, and repeated once to obtain a hydrogel containing cations.

Embodiment 2

[0031] A kind of preparation of cationic hydrogel, its preparation method comprises the following steps:

[0032] (1) Mix 10g of polyvinyl alcohol and 2g of cationic starch and dissolve in 100mL of water, stir and heat at 90°C for 2h, mix the polymer completely, and dissolve in water.

[0033] (2) The polymer aqueous solution was poured into the mold, frozen at -25°C for 20 hours, thawed at 25°C for 4 hours, and cycled 3 times to obtain a hydrogel containing cations.

Embodiment 3

[0035] A kind of preparation of cationic hydrogel, its preparation method comprises the following steps:

[0036] (1) Mix 10g of polyvinyl alcohol and 2g of cationic starch and dissolve in 100mL of water, stir and heat at 90°C for 2h, mix the polymer completely, and dissolve in water.

[0037] (2) The polymer aqueous solution was poured into the mold, frozen at -25°C for 22 hours, thawed at 25°C for 2 hours, and cycled 5 times to obtain a hydrogel containing cations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com