Underground long-distance water conveying pipe for municipal engineering and production process thereof

A long-distance water pipe technology, applied in the field of water pipes, can solve the problems of insufficient thermal insulation performance, short service life of pipes, weak impact resistance, etc., and achieve the effects of light weight, energy saving service life, environmental protection, and strong antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

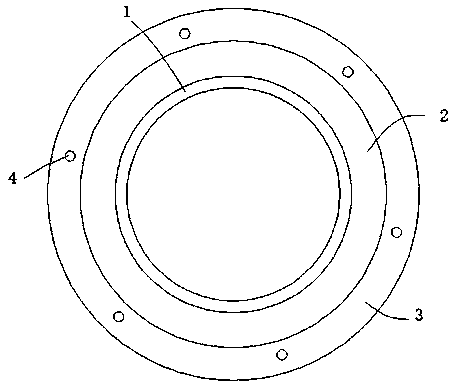

[0021] refer to figure 1 , an underground long-distance water delivery pipe for municipal engineering, comprising an inner casing 1, a buffer pipe 2 is arranged on the outside of the inner casing 1, an outer casing 3 is arranged on the outer side of the buffer pipe 2, and a hole is arranged on the outer casing 3 along the circumferential direction, An elastic metal wire 4 is arranged in the hole, and the inner casing 1 and the outer casing 3 are made of the same material.

[0022] The inner casing 1 and the outer casing 3 are made of the following raw materials in parts by weight: 50-95 parts of polyvinyl chloride resin, 6-15 parts of butyl rubber, 4-20 parts of nano-activated carbon fiber, and 3 parts of diethyl phthalate -8 parts, 7-10 parts of heat-expandable graphite, 9-15 parts of reinforcing fiber, 4-7 parts of silicon dioxide, 3-4 parts of compatibilizer, 1-8 parts of lubricant, 2-10 parts of antioxidant, Toughening agent 0.2-3.5 parts.

[0023] The reinforcing fiber ...

Embodiment 2

[0032] refer to figure 1 , an underground long-distance water delivery pipe for municipal engineering, comprising an inner casing 1, a buffer pipe 2 is arranged on the outside of the inner casing 1, an outer casing 3 is arranged on the outer side of the buffer pipe 2, and a hole is arranged on the outer casing 3 along the circumferential direction, An elastic metal wire 4 is arranged in the hole, and the inner casing 1 and the outer casing 3 are made of the same material.

[0033] The inner casing 1 and the outer casing 3 are made of the following raw materials in parts by weight: 70 parts of polyvinyl chloride resin, 8.5 parts of butyl rubber, 17 parts of nano-activated carbon fiber, 5.6 parts of diethyl phthalate, and 8 parts of thermally expandable graphite parts, 10 parts of reinforcing fiber, 5 parts of silica, 3 parts of compatibilizer, 4 parts of lubricant, 7 parts of antioxidant, and 0.26 parts of toughening agent.

[0034] The reinforcing fiber is one of Orlon fiber,...

Embodiment 3

[0043] refer to figure 1 , an underground long-distance water delivery pipe for municipal engineering, comprising an inner casing 1, a buffer pipe 2 is arranged on the outside of the inner casing 1, an outer casing 3 is arranged on the outer side of the buffer pipe 2, and a hole is arranged on the outer casing 3 along the circumferential direction, An elastic metal wire 4 is arranged in the hole, and the inner casing 1 and the outer casing 3 are made of the same material.

[0044] The inner casing 1 and the outer casing 3 are made of the following raw materials in parts by weight: 50 parts of polyvinyl chloride resin, 15 parts of butyl rubber, 4 parts of nano-activated carbon fiber, 8 parts of diethyl phthalate, and 10 parts of thermally expandable graphite parts, 9 parts of reinforcing fiber, 7 parts of silicon dioxide, 3 parts of compatibilizer, 8 parts of lubricant, 10 parts of antioxidant, and 3.5 parts of toughening agent.

[0045] The reinforcing fiber is one of Orlon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com