Construction of slender flexible filamentous particle model and numerical simulation method thereof

A numerical simulation and particle technology, applied in CAD numerical modeling, design optimization/simulation, etc., can solve the problem of not being able to characterize the complex motion characteristics of slender and flexible filamentous particles, the mass transfer and heat transfer process, and the real shape of tobacco shreds is very different. Far, tobacco easily deformed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

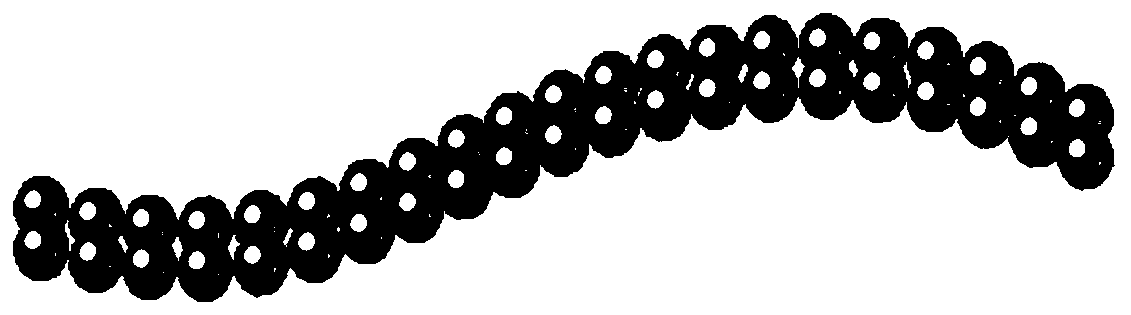

[0082] Attached below Figure 1-10 Embodiments of the present invention are described.

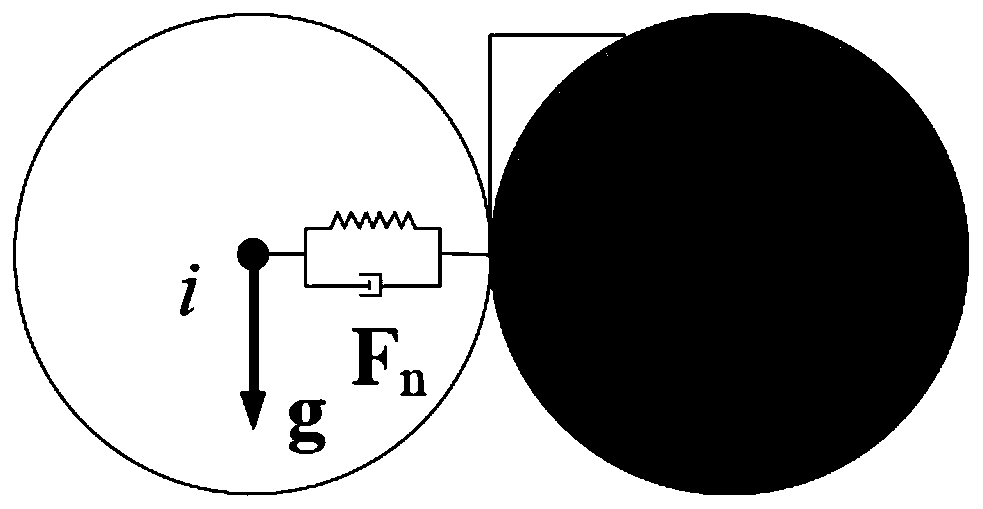

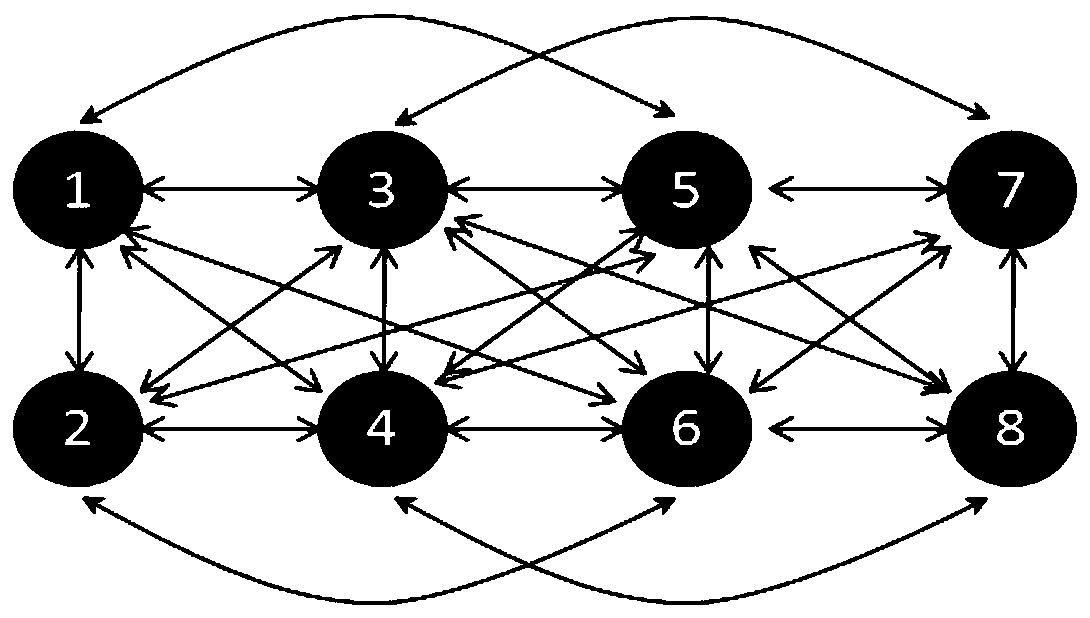

[0083] A construction of a slender and flexible filamentous particle model and its numerical simulation method. This embodiment is based on the construction of a slender and flexible filamentous particle model, and on the basis of the existing mathematical model of the large-scale computational fluid dynamics open source software OpenFoam, through Coupling the constructed elongated and flexible filamentary particle model with it, that is, the interaction mode of the elongated and flexible filamentary particle model (the structural form of the elongated and flexible filamentary particle model, the particle motion model of the elongated and flexible filamentary particle model and its inter-particle Constraint model), time step saving and output mechanism, to realize the numerical simulation of the gas-solid flow characteristics and value and heat transfer of slender and flexible filamentous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com