Protective agent for relieving fruit sunburn and preparation process thereof

A protective agent and fruit technology, applied in the field of plant protection, can solve the problems of ineffective control and incomplete control of sunburn, and achieve the effects of reducing damage, reducing fruit diseases, and pollution-free ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A protective agent for alleviating sunburn of fruits, comprising 6.8% titanium dioxide, 70% talc, 20% kaolinite, 3% gum arabic and 0.2% mannan by mass percentage.

[0024] The preparation technology of above-mentioned protective agent comprises the steps:

[0025] (1) Titanium dioxide, talc and kaolinite are pulverized by a Raymond mill to a fineness of 2000 mesh; gum arabic and mannan are pulverized by a jet mill to a fineness of 250 mesh to obtain pretreated raw materials.

[0026] (2) The above-mentioned pretreatment raw materials are weighed into the mixer according to the mass percentage as claimed in claim 1, and mixed by the mixer to obtain the protective agent.

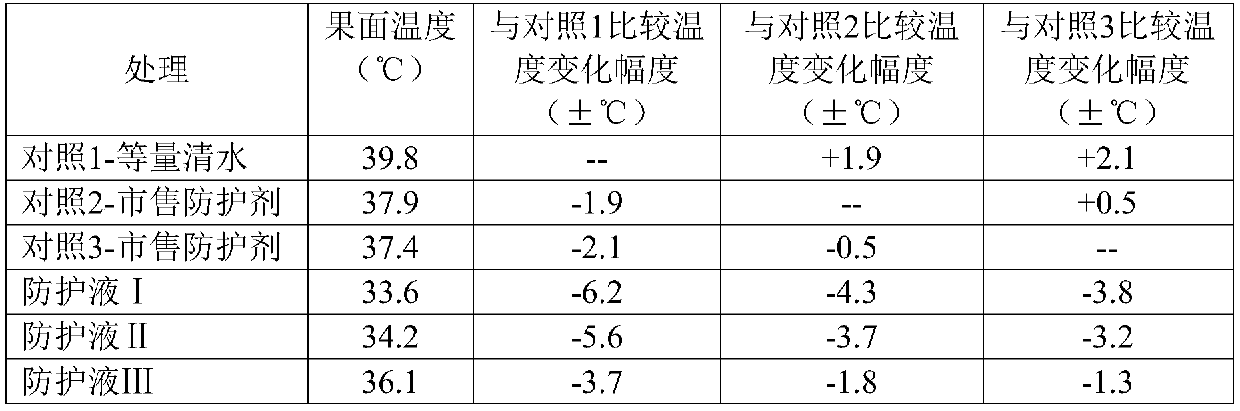

[0027] Protective effect test: The protective liquid was prepared with a mass ratio of protective agent and water of 1:50, and the citrus fruit surface was sprayed 3 times with an interval of 20 days between each time.

Embodiment 2

[0029] A protective agent for alleviating sunburn of fruits, comprising 8% titanium dioxide, 62% talc, 25% kaolinite, 4.5% gum arabic, and 0.5% mannan by mass percentage.

[0030] The preparation technology of above-mentioned protective agent comprises the steps:

[0031] (1) Titanium dioxide, talc and kaolinite are pulverized by a Raymond mill to a fineness of 1000 mesh; gum arabic and mannan are pulverized by a jet mill to a fineness of 200 mesh to obtain pretreated raw materials.

[0032] (2) The above-mentioned pretreatment raw materials are weighed into the mixer according to the mass percentage as claimed in claim 1, and mixed by the mixer to obtain the protective agent.

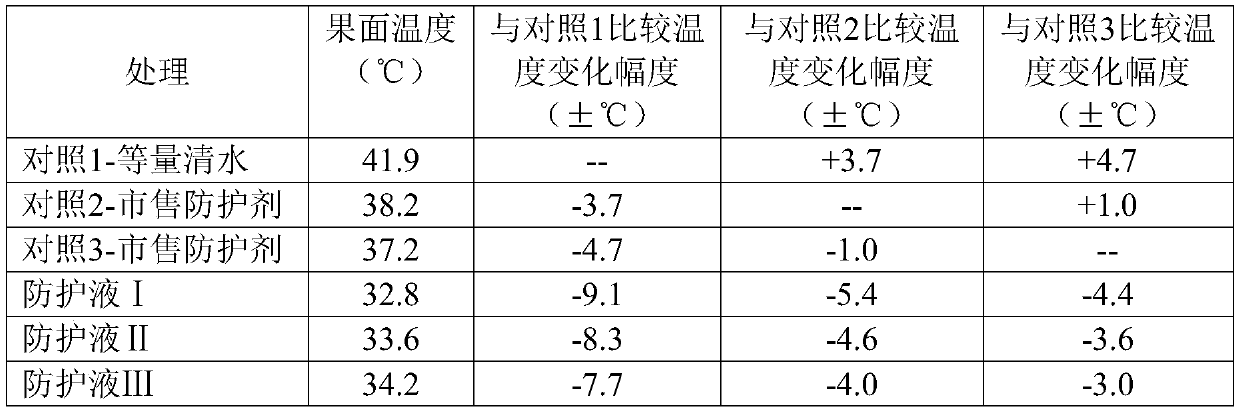

[0033] Protective effect test: Protective agent and water were prepared with a mass ratio of 1:30 to prepare a protective liquid, and sprayed on the mango fruit surface twice with an interval of 15 days between each time.

Embodiment 3

[0035] A protective agent for alleviating sunburn of fruits, comprising 5% titanium dioxide, 65% talc, 26% kaolinite, 3.3% gum arabic, and 0.7% mannan by mass percentage.

[0036] The preparation technology of above-mentioned protective agent comprises the steps:

[0037] (1) Titanium dioxide, talc and kaolinite are pulverized by a Raymond mill to a fineness of 1500 mesh; gum arabic and mannan are pulverized by a jet mill to a fineness of 220 mesh to obtain pretreated raw materials.

[0038] (2) The above-mentioned pretreatment raw materials are weighed into the mixer according to the mass percentage as claimed in claim 1, and mixed by the mixer to obtain the protective agent.

[0039] Protective effect test: Protective agent and water were prepared at a mass ratio of 1:45 to prepare a protective solution, which was sprayed on the walnut fruit surface twice with an interval of 18 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com