Micro-enzymolysis soybean milk and preparation method thereof

A soymilk and enzymatic hydrolysis technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of increased production cost of soymilk, limited absorption efficiency, and difficulty in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

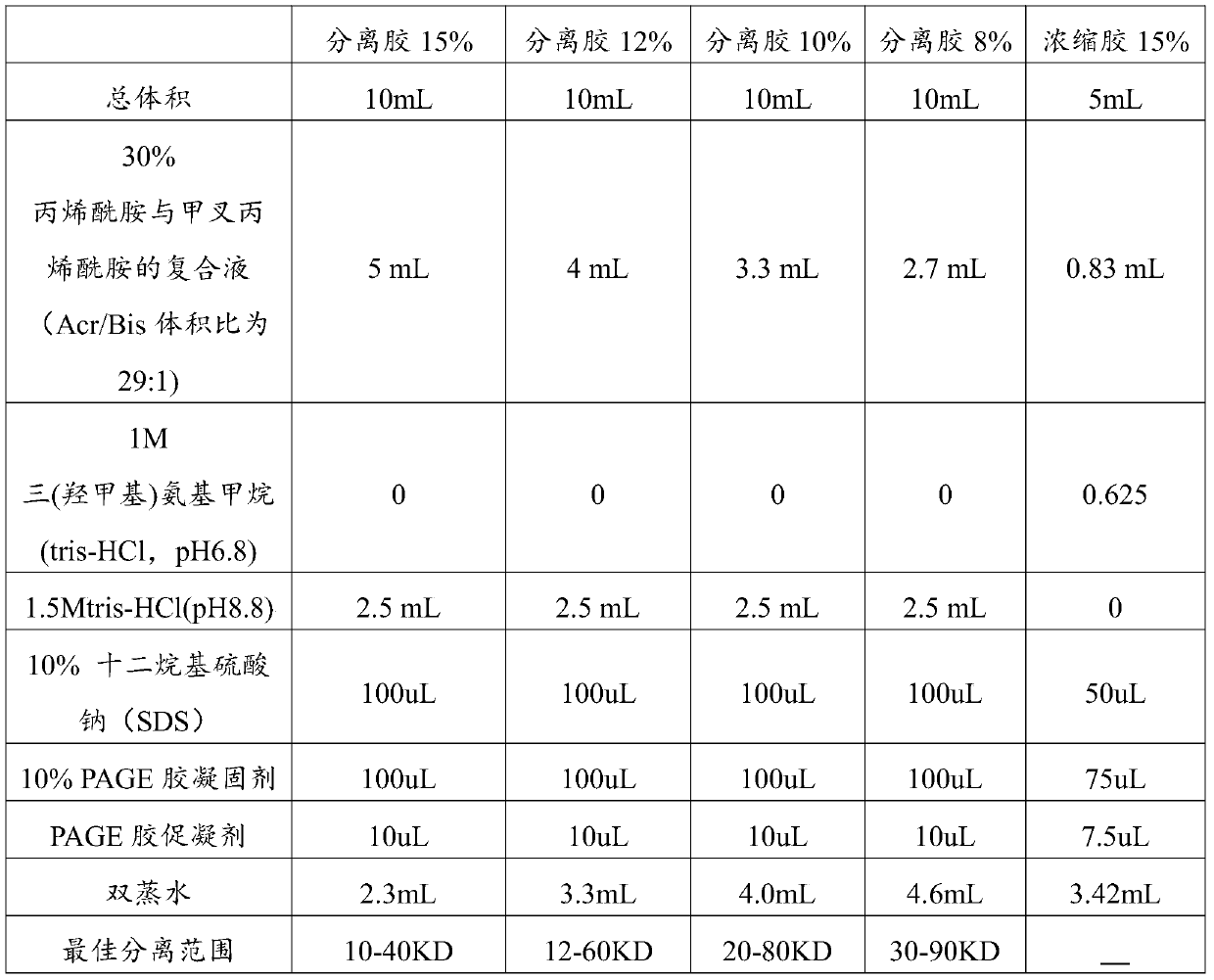

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing microenzymolysis soybean milk, comprising the following steps: (1) using NH 4 HCO 3 washing with water after soaking in an aqueous solution; refining the washed soybeans to obtain a slurry; filtering the slurry to obtain a slurry; (2) sequentially vacuum-concentrating and homogenizing the slurry to obtain a homogeneous liquid; (3) using neutral protease to carry out proteolysis of the homogeneous solution to obtain a primary enzymolysis solution; using pectinase and cellulase to perform a second enzymolysis on the primary enzymolysis solution to obtain an enzymolysis solution; (4) subjecting the enzymatic hydrolysis solution to high-pressure steam treatment to obtain cooked soymilk; sterilizing the cooked soymilk to obtain aseptic cooked soymilk; (5) vacuum heating and dehydrating the aseptic cooked soymilk in sequence and cooling to obtain microenzyme hydrolyzed soybean milk.

[0031] The present invention uses soybean NH...

Embodiment 1

[0039] (1) After washing the soybeans, put in 0.5% NH 4 HCO 3 Soak in an aqueous solution for 4 hours at 50°C, take out the soybeans and rinse them with water three times, then add 5 times the mass of deionized water to adjust the pH value to 6.5, heat to 95°C, pour into a water mill for refining, The obtained slurry is filtered through a 150-mesh sieve, and the bean dregs are added to 2 times the mass fraction of deionized water, stirred evenly, filtered through a 150-mesh sieve again, and the two filtrates are combined to obtain a slurry;

[0040] (2) Concentrate the slurry in the above step (1) in vacuum (vacuum degree 0.08MPa) to 30% of the original mass, then place the concentrated solution in an ultrasonic homogenizer with a pump pressure of 0.8MPa and a frequency of 25mHz, and carry out Homogenize for 8 minutes to obtain a homogeneous solution;

[0041] (3) all take the homogeneous liquid that step (2) obtains as consumption benchmark, set the consumption of neutral p...

Embodiment 2

[0046] A method for producing microenzyme hydrolyzed soymilk, the method for producing polypeptide-enhanced soymilk comprises the following steps:

[0047] (1) After washing the soybeans, put in 0.3% NH 4 HCO 3 The temperature of the aqueous solution is soaked at 40°C for 5 hours, the soybeans are taken out and rinsed twice with clean water, then added to 5 times the mass fraction of deionized water to adjust the pH value to 7.0, heated to 85°C, and poured into a water mill for refining. The obtained slurry is filtered through a 150-mesh sieve, and the bean dregs are added to 2 times the mass fraction of deionized water, stirred evenly, filtered through a 150-mesh sieve again, and the two filtrates are combined to obtain a slurry;

[0048] (2) Concentrate the slurry in the above step (1) in vacuum (vacuum degree 0.09MPa) to 1 / 3 of the original mass, then place the concentrated solution in an ultrasonic homogenizer with a pump pressure of 0.8MPa and a frequency of 25mHz, Carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com