A kind of manufacturing process of metal film screen plate

A manufacturing process and metal film technology, which is applied in the field of metal film screen plate manufacturing process, can solve the problems of undisclosed process details and methods, and achieve the effects of flexible bonding, high production efficiency, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

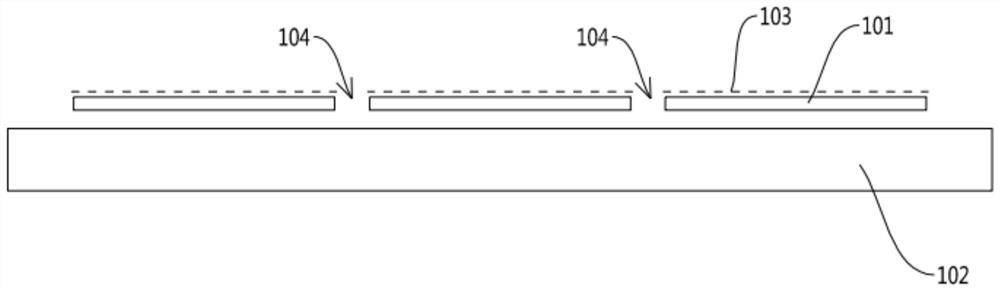

[0036] see figure 1 As shown, in the manufacturing process of a metal film screen involved in this embodiment, the metal film 101 is fixed on the transfer film 102, and then the glue that plays the adhesive function after heating is attached to the metal film 101 -103, through laser engraving, remove excess metal film-101 and glue-103 (that is, gap-104) to achieve the desired shape, and combine with the screen by hot pressing.

Embodiment 2

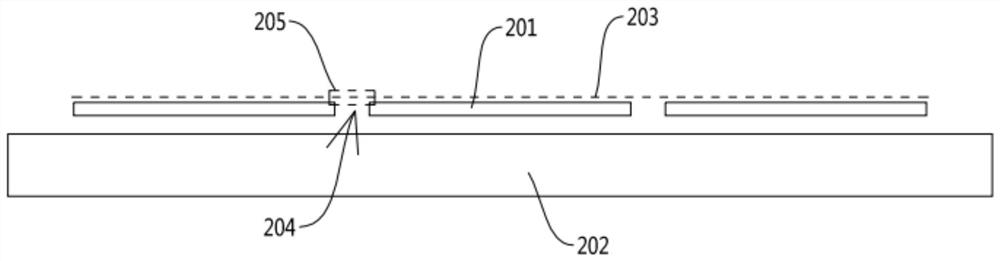

[0038] see figure 2 As shown, in the manufacturing process of a metal film screen involved in this embodiment, the metal film 201 is fixed on the transfer film 202, and the redundant metal film 201 is removed by laser engraving or electroforming (ie Gap 2 204), to reach the desired shape, and then attach the glue 2 203 that has been heated to play an adhesive function on the metal film 2 201, and remove the excess glue 2 (that is, the gap 3 205) by laser engraving to achieve the same The metal film 2 201 forms the same structure, and then combined with the screen by hot pressing.

[0039] In this solution, the metal film 201 and the glue 203 are cut separately, so that the metal film 201 can be electroformed, and the glue 203 can be laser engraved, so that the requirements for the laser are reduced. Among them, electroforming can also be replaced by etching operation.

Embodiment 3

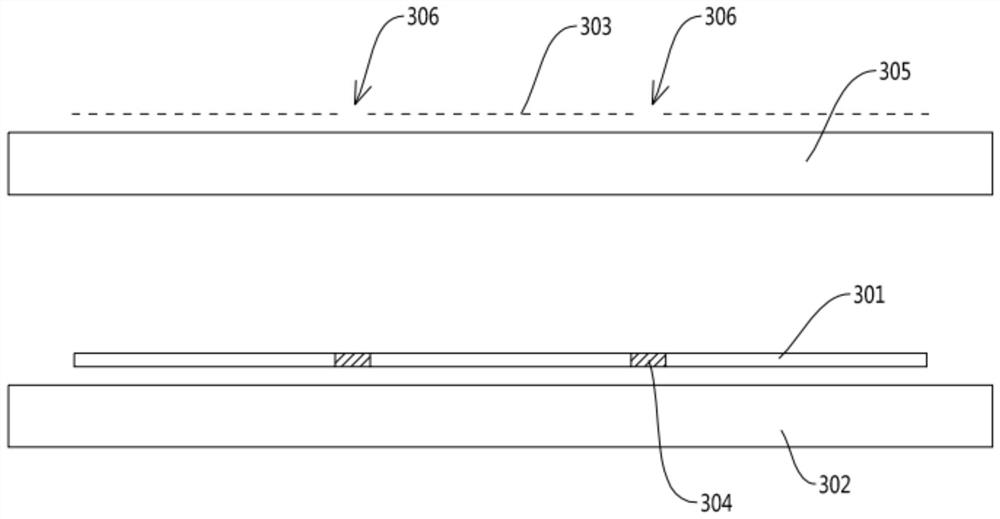

[0041] see image 3 with Figure 4 As shown, in the manufacturing process of a metal film screen involved in this embodiment, the metal film 301 is fixed on the transfer film 302, and the redundant metal film 301 is removed by laser engraving or electroforming (ie Gap 4 304) reaches the desired shape; meanwhile, glue 3 303 is fixed on the transfer film 4 305, and excess glue 3 303 (that is, gap 5 306) is removed by laser engraving to form with the metal film 3 301 With the same structure, first hot press the glue three 303 onto the metal film three 301, and then heat press the metal film three 301 to the screen through the glue three 303.

[0042] In this solution, the metal film 301 and the glue 303 are cut separately, so that the metal film 301 can be electroformed, and the glue 303 can be engraved by laser, so that the requirements for the laser are reduced. Among them, electroforming can also be replaced by etching operation.

[0043]The manufacturing process of the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com