A method for adding metal powder and inorganic salt to remove arsenic and chlorine in polluted acid

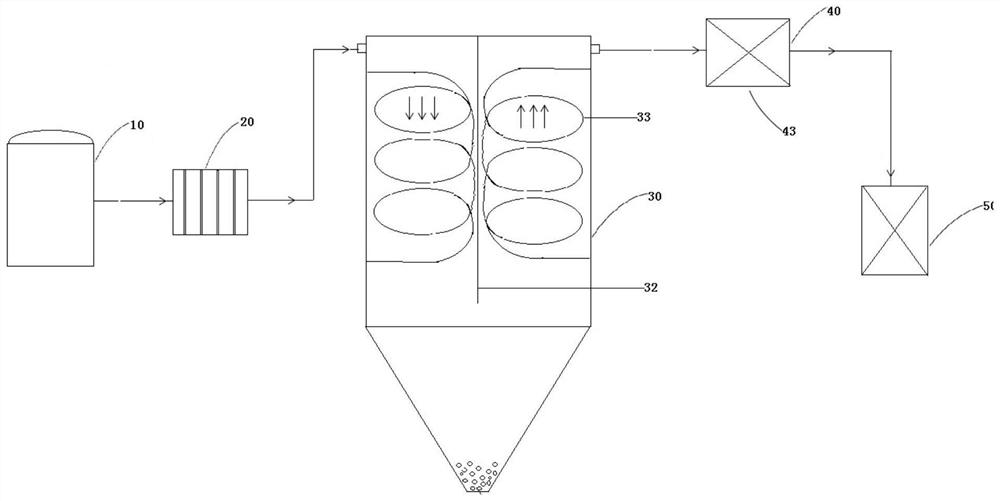

A technology of metal powder and metal addition, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problem of large acid consumption and water consumption, high cost of gypsum slag treatment, and difficult reprocessing of polluted acid. and other problems, to achieve the effect of reducing the amount of slag, improving economic and environmental benefits, and shortening the processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

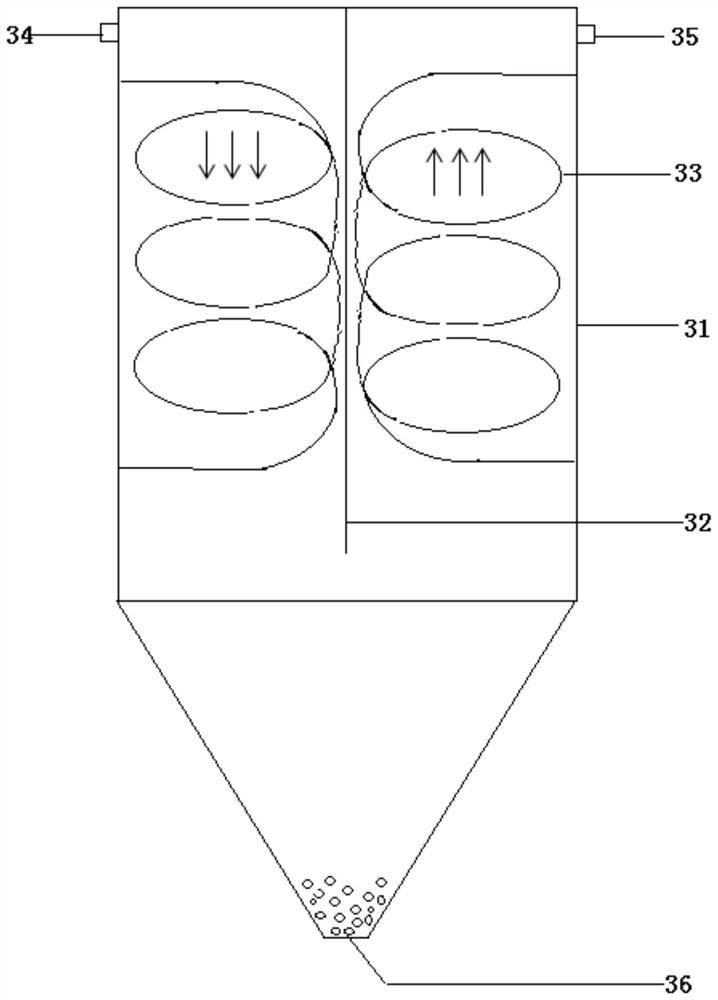

Method used

Image

Examples

Embodiment 1

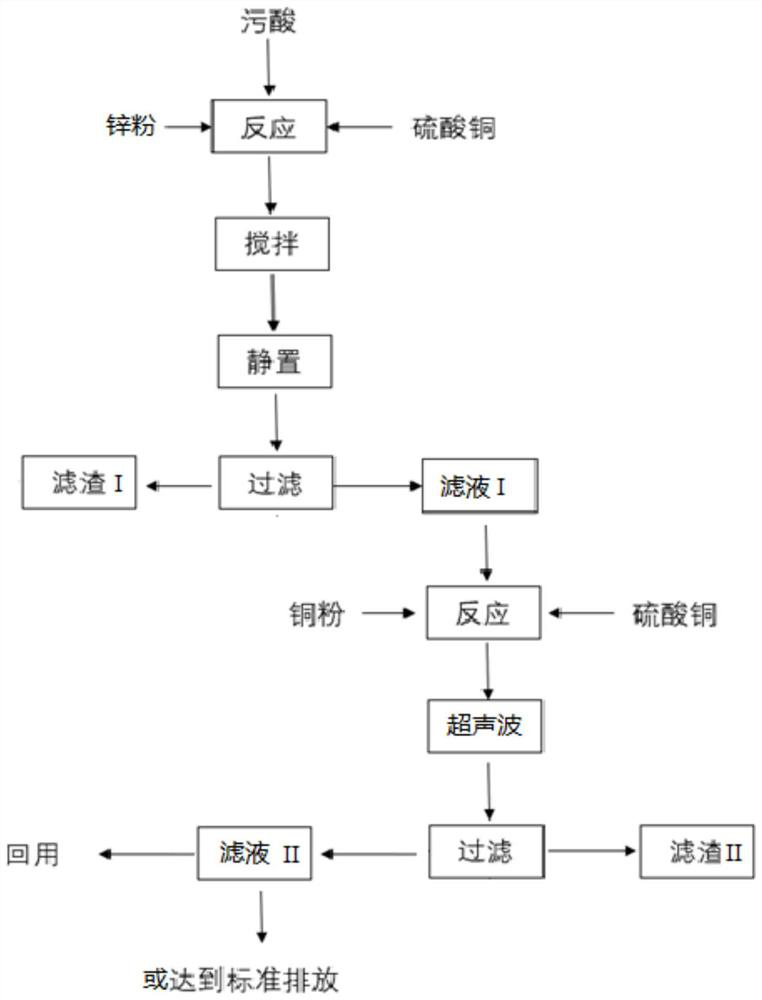

[0177] Take 100mL of dirty acid solution and put it into the reaction kettle, start stirring (100 rpm), and preheat to 35°C, the dirty acid contains As (as H 3 AsO 3 form) 735mg / L, Cl (as Cl - form) 1300mg / L, Pb (as Pb 2+ form) 116mg / L, Cd (as Cd 2+ form) 101.7mg / L, F (in the form of F - form) 456mg / L, pH=1.2;

[0178] Add 0.255g zinc powder, 8.6mL of copper sulfate solution of 50g / L in polluted acid simultaneously, continue to stir (100 revs / min) reaction, the reaction time is 10 minutes, obtains solid-liquid mixture I; Above-mentioned solid-liquid mixture I is extracted Filter, obtain filtrate I and filter residue I, measure the content of arsenic in filtrate I, contain As (with H 3 AsO 3 form) 43.96mg / L, in the above reaction process, the removal rate of arsenic is 94.0%;

[0179] Take the filtrate I and place it in the reactor, start stirring (100 rpm), and heat to 35°C, add copper powder and copper sulfate solution, 0.094g copper powder, 3.9mL of 50g / L copper sulfa...

Embodiment 2

[0181] Take 100mL of dirty acid solution and put it into the reaction kettle, start stirring (100 rpm), and preheat to 35°C, the dirty acid contains As (as H 3 AsO 3 form) 790mg / L, Cl (as Cl - form) 1025mg / L, Pb (as Pb 2+ form) 198mg / L, Cd (as Cd 2+ form) 98mg / L, F (in the form of F - form) 502mg / L, pH=1.0;

[0182] Add 0.273g zinc powder, 9.1mL of copper sulfate solution of 50g / L in polluted acid simultaneously, continue to stir (100 revs / min) reaction, the reaction time is 10 minutes, obtains solid-liquid mixture I; Above-mentioned solid-liquid mixture I is pumped Filter, obtain filtrate I and filter residue I, measure the content of arsenic in filtrate I, contain As (with H 3 AsO 3 form) 48.98mg / L; in the above-mentioned reaction process, the removal rate of arsenic is 93.8%;

[0183] Get the filtrate I and place it in the reactor, start stirring (100 rev / min), and heat to 35°C, add copper powder and copper sulfate simultaneously, 0.616g copper powder, 12.3mL of copp...

Embodiment 3

[0185] Take 100mL of dirty acid solution and put it into the reaction kettle, start stirring (100 rpm), and preheat to 35°C, the dirty acid contains As (as H 3 AsO 3 form) 483mg / L, Cl (as Cl - form) 1103mg / L, Pb (as Pb 2+ form) 156mg / L, Cd (as Cd 2+ form) 86.5mg / L, F (in the form of F - form) 598mg / L, pH=1.5;

[0186] Add 0.167g zinc powder, 5.6mL of copper sulfate solution of 50g / L in polluted acid simultaneously, continue stirring (100 revs / min) reaction, the reaction time is 10 minutes, obtains solid-liquid mixture I; Above-mentioned solid-liquid mixture I is pumped Filter, obtain filtrate I and filter residue I, measure the content of arsenic in filtrate I, contain As (with H 3 AsO 3 form) 28.49mg / L; in the above-mentioned reaction process, the removal rate of arsenic is 94.1%;

[0187] Get the filtrate I and place it in the reactor, start stirring (100 rev / min), and heat to 35°C, add copper powder and copper sulfate simultaneously, 0.706g copper powder, 29.4mL of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com