Ceramic slurry, ceramic diaphragm and lithium ion battery

A technology of ceramic slurry and ceramic diaphragm, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems that the trend of diaphragm thinning is contradictory, the anti-lithium dendrite puncture ability has not been greatly improved, and needs to be improved. , to achieve good anti-lithium dendrite puncture performance, excellent electronic barrier properties, and excellent anti-lithium dendrite puncture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

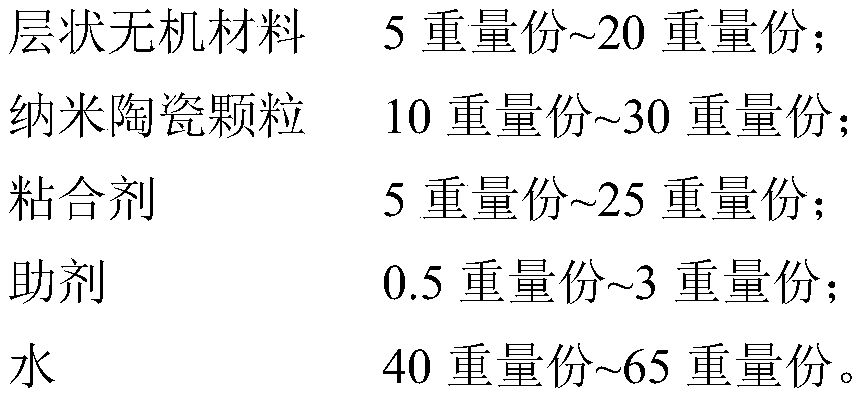

[0054] 15g of montmorillonite, 25g of nano-ceramic particles, 5g of polymethyl methacrylate and 2.5g of fatty alcohol polyoxyethylene ether were evenly dispersed into 52.5g of water under stirring, and a ceramic slurry was prepared by sand milling, wherein the montmorillonite The diameter-thickness ratio of the soil is 200-350, and the specific surface area is 240m 2 / g, the average wafer thickness is less than 25nm. A polyethylene film with a thickness of 5 μm prepared by Lucky Film Co., Ltd. was used as the base film. After the ceramic slurry is prepared, the prepared ceramic slurry is evenly coated on one surface of the base film with a wire rod, and then dried in an oven at 70°C to evaporate the water to obtain a ceramic with a ceramic coating thickness of 3 μm. diaphragm.

Embodiment 2

[0056] Disperse 10g of montmorillonite, 30g of nano-ceramic particles, 8g of polymethyl methacrylate and 2g of fatty alcohol polyoxyethylene ether into 50g of water evenly under stirring, and prepare a ceramic slurry through sand milling, wherein the hydrotalcite powder The ratio of diameter to thickness is 350-400, and the specific surface area is 550m 2 / g, the average wafer thickness is less than 25nm. A polyethylene film with a thickness of 7 μm prepared by Lucky Film Co., Ltd. was used as the base film. After preparing the ceramic slurry, the prepared ceramic slurry was evenly coated on one surface of the base film with a wire rod, and then dried in an oven at 70°C to evaporate the water to obtain a ceramic coating with a thickness of 2.5 μm. Ceramic diaphragm.

Embodiment 3

[0058] 5g of montmorillonite, 35g of nano-ceramic particles, 3g of polymethyl methacrylate and 0.5g of fatty alcohol polyoxyethylene ether were uniformly dispersed into 50g of water under stirring, and prepared into a ceramic slurry by sand milling, wherein the montmorillonite The diameter-thickness ratio is 150-200, and the specific surface area is 150m 2 / g, the average wafer thickness is less than 25nm. A polyethylene film with a thickness of 16 μm prepared by Lucky Film Co., Ltd. was used as the base film. After the ceramic slurry is prepared, the prepared ceramic slurry is evenly coated on one surface of the base film with a wire rod, and then dried in an oven at 70°C to evaporate the water to obtain a ceramic with a ceramic coating thickness of 2 μm. diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com