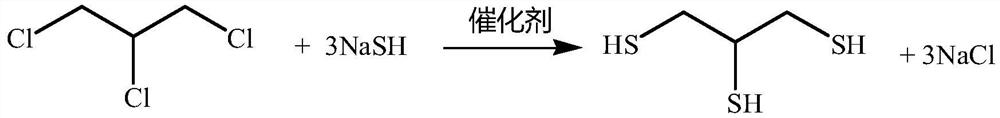

A kind of preparation method of 1,2,3-trimercaptopropane

A technology of trimercaptopropane and trichloropropane, which is applied in the field of chemical technology, can solve problems such as no relevant reports on synthesis technology, and achieve the effects of high added value of products, simple process, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Into a 1000mL four-necked flask equipped with a glass stirring and thermometer was sequentially added 147.5g of trichloropropane, 700g of 32% sodium hydrosulfide and 1.47g of tetrabutylammonium chloride;

[0032] (2) Turn on the stirring, heat it to 90°C in an oil bath for 4 hours of heat preservation reaction;

[0033] (3) After the reaction is completed, transfer the product to a separatory funnel, let stand for 15 minutes, and cut the lower organic phase into a 500mL four-neck flask;

[0034] (4) Add 221g of deionized water to the organic phase, start stirring, add 50% sulfuric acid aqueous solution to adjust the pH of the system to 4, heat up to 50-60℃, stir for 15 minutes, and then transfer to the separatory funnel. , Let stand for 15min and cut the lower organic phase into a four-neck flask;

[0035] (5) Add 221g of deionized water to the four-necked flask, raise the temperature to 50-60℃ and stir for 15min for the first water washing. After completion, transfer to th...

Embodiment 2

[0040] (1) Into a 1000 mL four-necked flask equipped with a glass stirring and thermometer was sequentially added 147.5 g of trichloropropane, 876 g of 32% sodium hydrosulfide and 0.74 g of benzyl triethylammonium chloride;

[0041] (2) Turn on the stirring and heat it to 60°C in an oil bath for 5 hours of insulation reaction;

[0042] (3) After the reaction is completed, transfer the product to a separatory funnel, let stand for 15 minutes, and cut the lower organic phase into a 500mL four-neck flask;

[0043] (4) Add 221g of deionized water to the organic phase, start stirring, add 50% sulfuric acid aqueous solution to adjust the pH of the system to 5, heat up to 50-60℃, stir for 15 minutes, and then transfer to the separatory funnel. , Let stand for 15min and cut the lower organic phase into a four-neck flask;

[0044] (5) Add 221g of deionized water to the four-necked flask, raise the temperature to 50-60℃ and stir for 15min for the first water washing. After completion, transfer ...

Embodiment 3

[0049] (1) Into a 1000mL four-necked flask equipped with glass stirring and thermometer was sequentially added 147.5g of trichloropropane, 525.6g of 32% sodium hydrosulfide and 2.21g of tetrabutylammonium bromide;

[0050] (2) Turn on the stirring, heat it to 100°C in an oil bath, and conduct a heat preservation reaction for 3 hours;

[0051] (3) After the reaction is completed, transfer the product to a separatory funnel, let stand for 15 minutes, and cut the lower organic phase into a 500mL four-neck flask;

[0052] (4) Add 221g of deionized water to the organic phase, start stirring, add 50% sulfuric acid aqueous solution to adjust the pH of the system to 3, heat up to 50-60°C, stir for 15 minutes, and then transfer to a separatory funnel. , Let stand for 15min and cut the lower organic phase into a four-neck flask;

[0053] (5) Add 221g of deionized water to the four-necked flask, raise the temperature to 50-60℃ and stir for 15min for the first water washing. After completion, tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com