Novel polyurethane composite material for wall decoration and preparation method thereof

A polyurethane composite material and wall technology, which is applied in the field of polyurethane synthetic materials, can solve the problems of resource waste, high cost, and insufficient strength, and achieve the effects of low VOC, appropriate performance, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

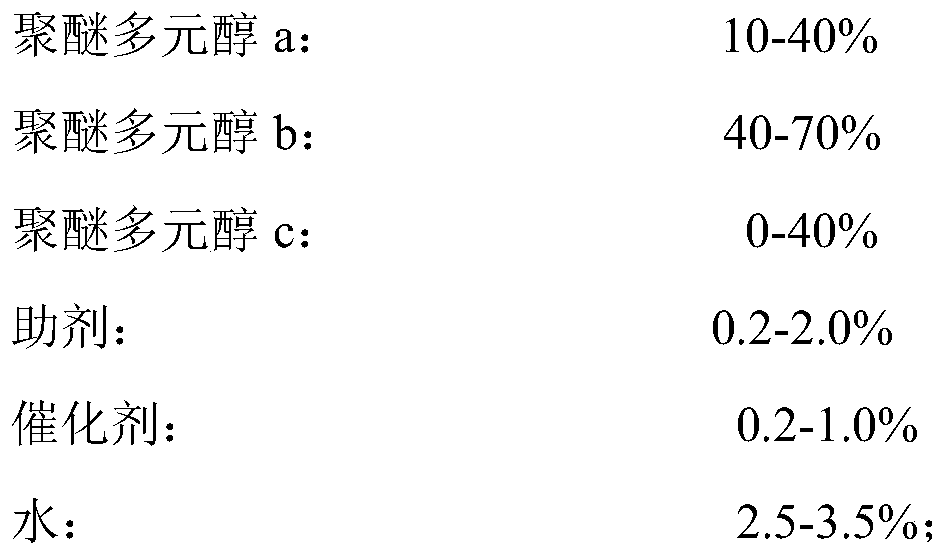

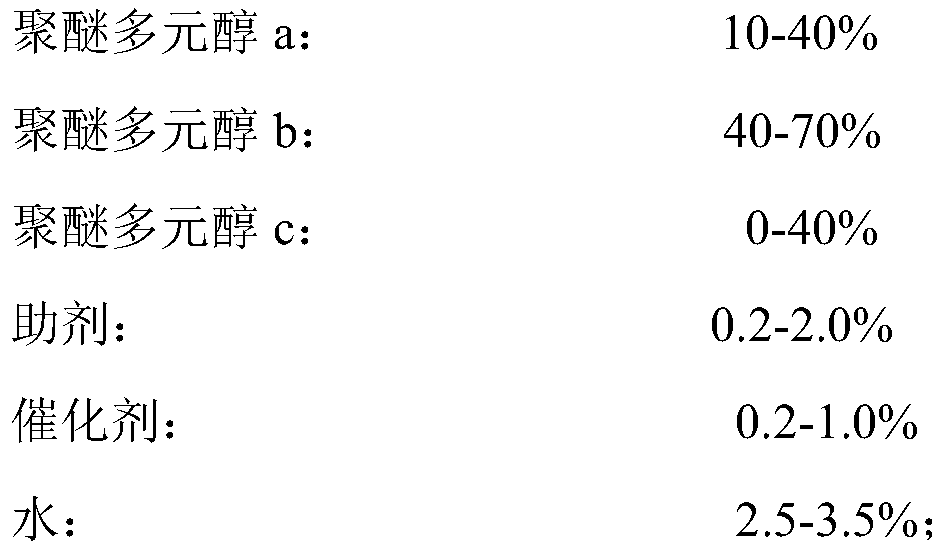

Method used

Image

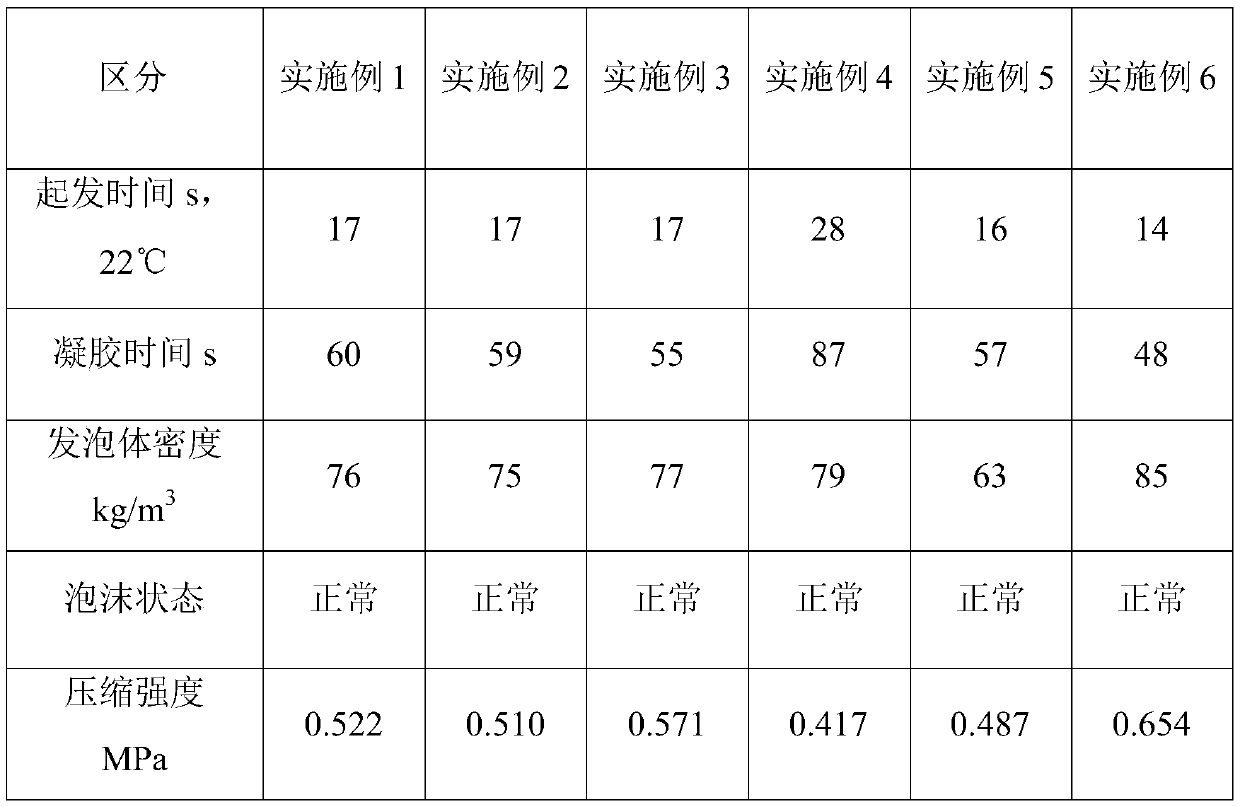

Examples

Embodiment 1

[0035] (1) Prepare 100Kg of component A material, respectively weigh polyether polyol a (F330N, Novel) 19.2Kg, polyether polyol b (C3050A, Novel) 52.9Kg, polyether polyol c (F628 , a Novel) 23.8Kg, water 3.2Kg, cell opener a (O-501,) 0.3Kg, catalyst a (bis(dimethylaminoethyl) ether) 0.1Kg, catalyst b (N,N-dimethyl Cyclohexylamine) 0.5Kg, put the weighed polyether polyol and water into the mixing tank and stir, then add the weighed cell opener and catalyst, add them to the reactor in turn, stir evenly at room temperature, and take samples After passing the test, it can be loaded into barrels.

[0036] (2) Prepare 100Kg of component B material, accurately measure polymethylene polyphenyl polyisocyanate 44V20L (Byer) 75Kg, plasticizer (dioctyl phthalate) 25Kg, put into the reaction kettle in order, stir and mix for 1 Hours, after the sampling test is qualified, the material is discharged, and the nitrogen is replaced with a sealed package.

[0037] Mix A and B components accord...

Embodiment 2

[0039] The novel wall interior material is prepared from the following components according to the following steps:

[0040] (1) Prepare 100Kg of component A material, weigh polyether polyol a (F330N, Novel) 23.8Kg, polyether polyol b (C3050A, Novel) 46.9Kg, polyether polyol c (F628 , Novel) 23.8Kg, water 3.2Kg, foam stabilizer a (F8001A, Novel) 1Kg, foam stabilizer b (L-580, Momentive) 1Kg, catalyst a (bis(dimethylaminoethyl) ether) 0.1Kg, catalyst b (bismuth isooctanoate) 0.2Kg, put the weighed polyether polyol and water into the mixing kettle and stir, then add the weighed foam stabilizer and catalyst, and add them in the reaction kettle successively, Stir evenly at room temperature, and after sampling and testing pass, it can be filled into barrels.

[0041] (2) Prepare 100Kg of component B materials, accurately measure 75Kg of polymethylene polyphenyl polyisocyanate M20S (BASFSE), and 25Kg of plasticizer (chlorinated paraffin), put them into the reaction kettle in order,...

Embodiment 3

[0044] The novel wall interior material is prepared from the following components according to the following steps:

[0045] (1) Prepare 100Kg of component A material, weigh polyether polyol a (F330N, Novel) 24.3Kg, polyether polyol b (C3050A, Novel) 47.5Kg, polyether polyol c (F628 , a Novel) 24.1Kg, water 3.2Kg, cell opener a (O-501) 0.3Kg, catalyst a (bis(dimethylaminoethyl) ether) 0.1Kg, catalyst b (C1) 0.5Kg, will weigh Put the measured polyether polyol and water into the mixing tank and stir, then add the weighed cell opening agent and catalyst, add them to the reaction tank in turn, stir evenly at room temperature, and fill the tank after sampling and testing pass.

[0046] (2) Prepare 100Kg of component B material, accurately measure 75Kg of polymethylene polyphenyl polyisocyanate PM200 (Yantai Wanhua), and 25Kg of plasticizer (dioctyl phthalate) into the reaction kettle in order, stir and mix After 1 hour, after the sampling test is qualified, the material is dischar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com