Halogen-free flame retardant composition, halogen-free flame retardant masterbatch and high-fluidity high-oxygen-index glass fiber reinforced halogen-free flame-retardant polyamide

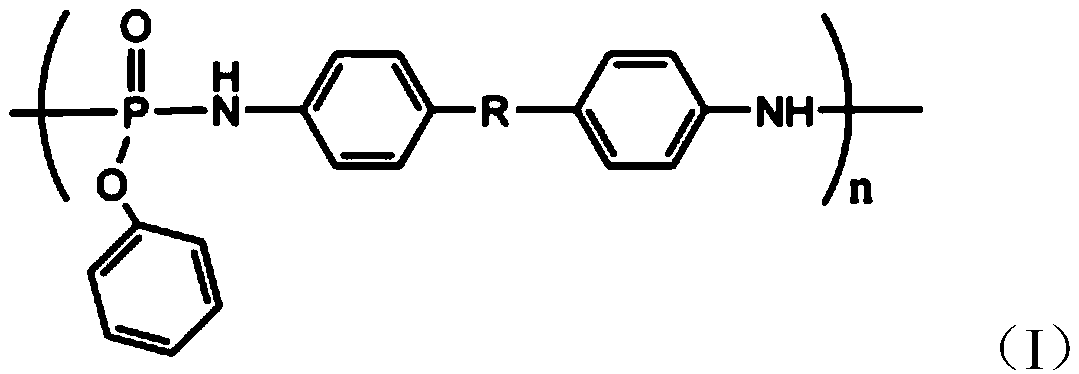

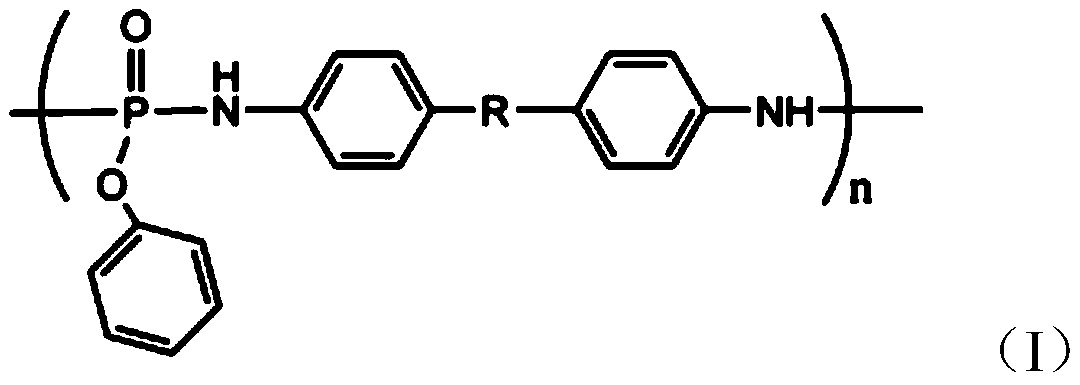

A technology of flame retardant polyamide and flame retardant, which is applied in the field of halogen-free flame retardant composition, halogen-free flame retardant masterbatch and high flow high oxygen index glass fiber reinforced halogen-free flame retardant polyamide, which can solve the problem of flame retardant Low combustion efficiency, unable to meet the application requirements of high flame retardancy, etc., to achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

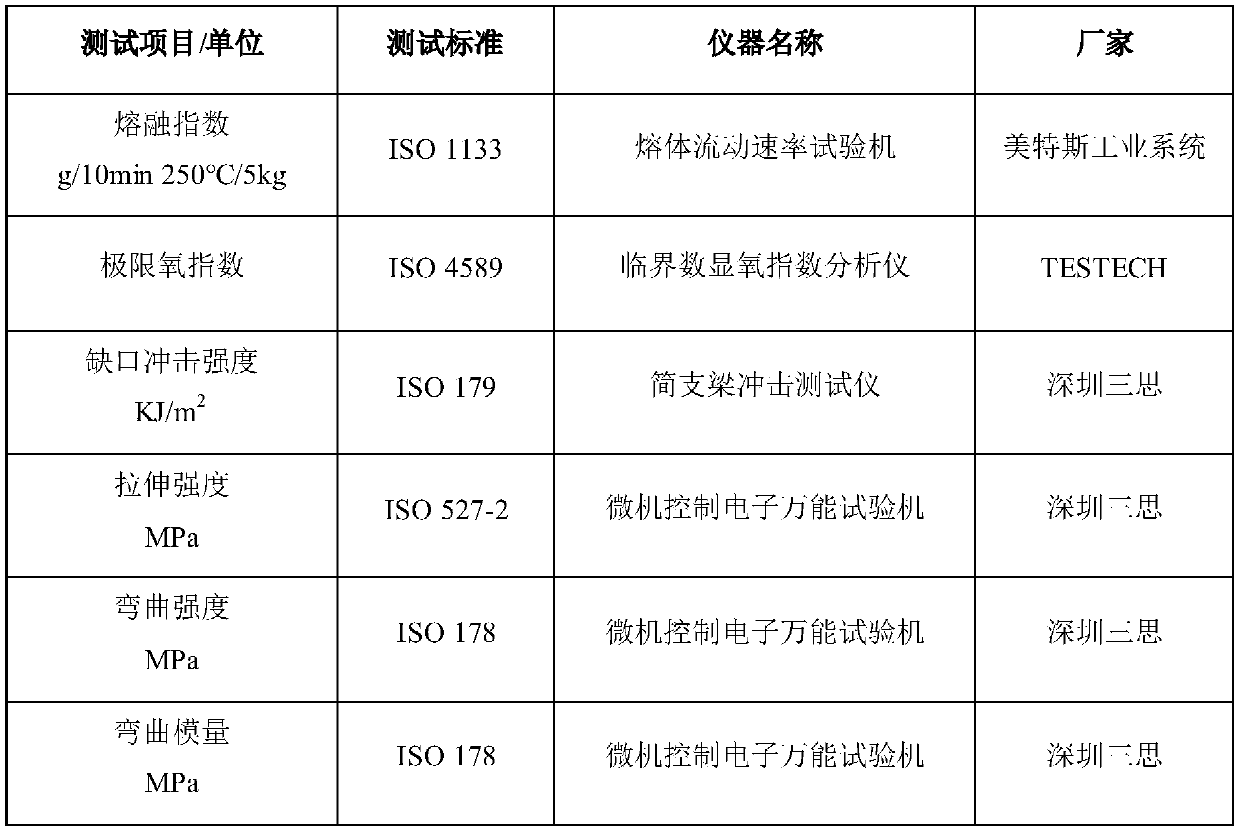

[0067] 70% by weight of sulfone-based polyphosphoramide (n=300), 25% by weight of triphenyl phosphate, and 5% by weight of zinc borate are uniformly mixed by a high-speed mixer to obtain a flame retardant composition powder. The above-mentioned flame-retardant composition powder agent is added to PA6 (M2500) resin at a concentration of 60 wt%, and the flame-retardant masterbatch is obtained by extruding and granulating through a twin-screw extruder at 220-250°C.

[0068] Based on the total weight of raw materials, 15wt% of the flame retardant masterbatch prepared in this implementation, 30wt% of glass fiber (GF), 55wt% of PA6 (M2500) and antioxidant 1098 / 168

[0069] (0.2wt% / 0.2wt%) blended, extruded and pelletized by a twin-screw extruder to obtain a halogen-free flame-retardant polyamide with high flow and high oxygen index.

[0070] After testing, the mechanical properties, melt index and limiting oxygen index data of the halogen-free flame-retardant polyamide prepared in this exa...

Embodiment 2

[0100] The raw material ratio and preparation process of the flame retardant composition, flame retardant masterbatch and halogen-free flame-retardant polyamide are exactly the same as in Example 1, except that the sulfone-based polyphosphoramide is used as the raw material, and n is selected from 500.

[0101] After testing, the mechanical properties, melt index and limiting oxygen index data of the halogen-free flame-retardant polyamide prepared in this example are listed in Table 4 below.

Embodiment 3

[0103] The raw material ratio and preparation process of the flame retardant composition, flame retardant masterbatch and halogen-free flame retardant polyamide are exactly the same as those in Example 1, except that the sulfone-based polyphosphoramide used as the raw material is replaced with alkyl polyphosphorus Amide (n is selected from 300).

[0104] After testing, the mechanical properties, melt index and limiting oxygen index data of the halogen-free flame-retardant polyamide prepared in this example are listed in Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com